Highway Safety Benefit–Cost

Analysis Guide

http://safety.fhwa.dot.gov

FHWA Safety Program

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE

FOREWORD

The purpose of the Highway Safety Benefit-Cost Analysis Guide (this Guide) is to assist

transportation agencies in making consistent and theoretically sound decisions for economically

evaluating and ranking safety countermeasures. Transportation professionals can use the

methods described to analyze both site-specific and systemic safety approaches with single or

multiple countermeasures. This Guide is intended as a user-friendly technical reference which

transportation professionals can use with no prior experience with economic evaluation

techniques. This Guide provides example calculations throughout the document to assist

transportation professionals in understanding benefit-cost analysis (BCA) concepts and applying

them for safety applications.

NOTICE

This document is disseminated under the sponsorship of the U.S. Department of

Transportation in the interest of information exchange. The U.S. Government assumes no

liability for the use of the information contained in this document.

The U.S. Government does not endorse products or manufacturers. Trademarks or

manufacturers’ names appear in this report only because they are considered essential to the

objective of the document.

QUALITY ASSURANCE STATEMENT

The Federal Highway Administration (FHWA) provides high-quality information to serve

Government, industry, and the public in a manner that promotes public understanding.

Standards and policies are used to ensure and maximize the quality, objectivity, utility, and

integrity of its information. FHWA periodically reviews quality issues and adjusts its programs

and processes to ensure continuous quality improvement.

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE

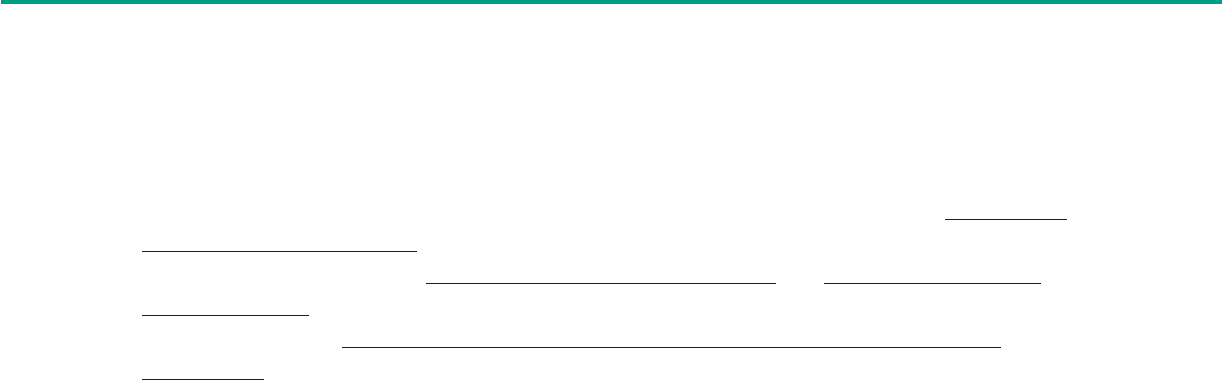

TECHNICAL DOCUMENTATION PAGE

1. Report No.

FHWA-SA-18-001

2. Government Accession

No.

3. Recipient's Catalog No.

4. Title and Subtitle

Highway Safety Benefit-Cost Analysis Guide

5. Report Date

February 2018

6. Performing Organization Code

7.Author(s)

Michael Lawrence, Alan Hachey, Geni Bahar, and Frank Gross

8. Performing Organization Report No.

9. Performing Organization Name and Address

VHB

Venture I

940 Main Campus Drive, Suite 500

Raleigh, NC 27606

10. Work Unit No.

11. Contract or Grant No.

DTFH61-16-D-00005 (VHB)

12. Sponsoring Agency Name and Address

Federal Highway Administration Office of Safety

1200 New Jersey Ave., SE

Washington, DC 20590

13. Type of Report and Period

Final Draft Report, August 2016-

February 2018

14. Sponsoring Agency Code

FHWA

15. Supplementary Notes

The contract manager for this report was Karen Scurry, FHWA. The task was led by Jack Faucett Associates.

16. Abstract

The purpose of the Highway Safety Benefit-Cost Analysis (BCA) Guide is to assist transportation agencies in making

consistent and sound investment decisions. The target audience includes transportation professionals such as traffic

engineers, highway safety engineers, and planners conducting highway safety BCA for projects and programs. This Guide

will help these users to quantify the costs, and direct and indirect safety-related benefits of project alternatives. Direct

safety benefits include the expected change in crash frequency and severity. Indirect benefits include the operational and

environmental benefits that result from a reduction in crashes (e.g., reduced delay, fuel use, and emissions). Readers will

understand the methods, data requirements, and considerations associated with BCA. Examples demonstrate the application

of the methods in various scenarios, including both site-specific and systemic projects with single or multiple

countermeasures. Conducting consistent and reliable BCA will support decision making, optimize the return on

investments, and increase the effectiveness of projects and programs.

17. Key Words:

safety, economic analysis, lifecycle analysis,

benefit-cost analysis, crash cost

18. Distribution Statement

No restrictions.

19. Security Classif. (of this report)

Unclassified

20. Security Classif. (of this

page) Unclassified

21. No. of Pages

160

22. Price

Form DOT F 1700.7 (8-72) Reproduction of completed pages authorized

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE

ii

ACKNOWLEDGEMENTS

The authors would like to thank the Technical Advisory Committee (TAC) of the Highway

Safety Manual Implementation Transportation Pooled-Fund Study for providing input and

recommendations on the organization and content of this Guide. The TAC has been invaluable

in identifying areas of the greatest need for guidance as well as reviewing the guidance materials

and application of the techniques presented. The TAC is comprised of individuals representing

State transportation agencies throughout the United States.

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE

iii

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE

iv

TABLE OF CONTENTS

1. Overview of Guide ................................................................................................... 1

1.1 Introduction and Purpose .................................................................................................................1

1.2 Target Audience ..................................................................................................................................2

1.3 Structure of the Guide .......................................................................................................................2

2. Overview of BCA for Safety .................................................................................... 3

2.1 What is Benefit-Cost Analysis? ........................................................................................................3

2.2 What is Safety Management? ............................................................................................................4

2.3 Economic Measures for BCA ...........................................................................................................7

2.4 Use of Highway Safety BCA in Safety Management and Project Development ................. 10

2.5 Highway Safety BCA Resources ................................................................................................... 14

2.6 Chapter Summary ............................................................................................................................ 17

3. Introduction to Project Costs ................................................................................ 19

3.1 Initial Costs ........................................................................................................................................ 20

3.2 Continuing Costs ............................................................................................................................. 20

3.3 Rehabilitation and End-of-Life Costs ........................................................................................... 21

3.4 Data Sources for Project Costs .................................................................................................... 22

3.5 Chapter Summary ............................................................................................................................ 22

4. Introduction to Project Benefits and Externalities .............................................. 23

4.1 Safety ................................................................................................................................................ 24

4.2 Travel Time ....................................................................................................................................... 30

4.3 Travel Time Reliability .................................................................................................................... 34

4.4 Vehicle Operating Costs ................................................................................................................ 38

4.5 Externalities ....................................................................................................................................... 40

4.6 Chapter Summary ............................................................................................................................ 44

5. Preparing for a BCA............................................................................................... 47

5.1 Developing the Project Base Condition...................................................................................... 47

5.2 Setting an Analysis Period .............................................................................................................. 50

5.3 Evaluating Uncertainty..................................................................................................................... 51

5.4 Discounting ........................................................................................................................................ 53

5.5 Challenges and Opportunities ....................................................................................................... 56

5.6 Chapter Summary ............................................................................................................................ 59

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE

v

6. Conducting BCA for Safety ................................................................................... 61

6.1 Estimating Safety Benefits ............................................................................................................... 61

6.2 Estimating Travel Time Benefits.................................................................................................... 71

6.3 Estimating Travel Time Reliability Benefits ................................................................................. 73

6.4 Estimating Vehicle Operating Cost Benefits .............................................................................. 75

6.5 Estimating Emissions Benefits ........................................................................................................ 77

6.6 Chapter Summary ............................................................................................................................ 78

7. Project Applications ............................................................................................... 79

7.1 Single Countermeasure Example .................................................................................................. 79

7.2 Multiple Countermeasure Example #1 ....................................................................................... 94

7.3 Multiple Countermeasure Example #2 ..................................................................................... 103

7.4 Multiple Sites (Systemic) Example .............................................................................................. 112

8. Communicating BCA Results .............................................................................. 129

8.1 Considerations for Presenting BCA Results ............................................................................ 129

8.2 Example Summaries of BCA Results ......................................................................................... 130

8.3 Chapter Summary .......................................................................................................................... 137

9. Summary .............................................................................................................. 139

References .................................................................................................................. 143

Appendix A: Glossary of Terms ................................................................................ 147

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE

vi

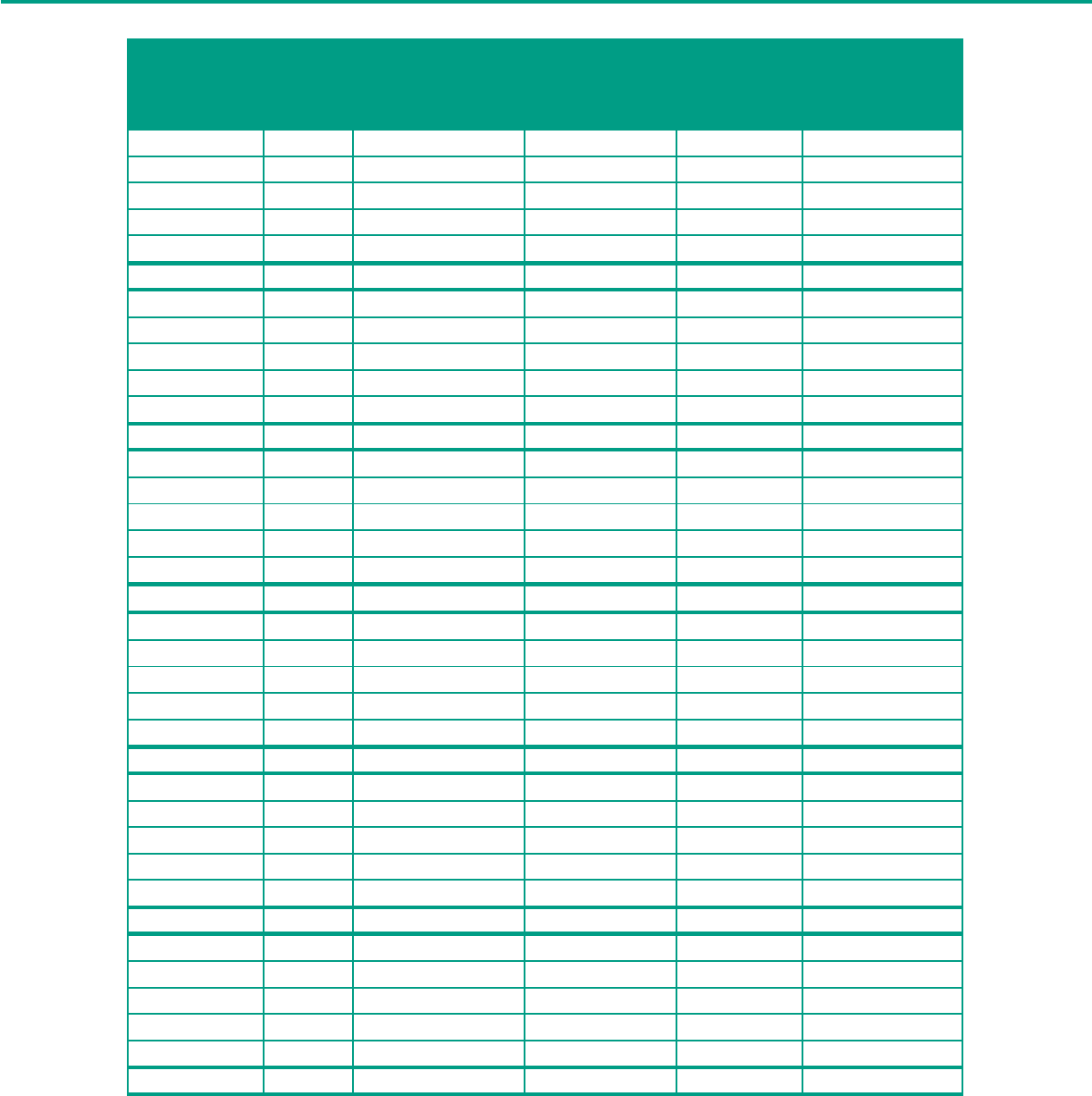

LIST OF TABLES

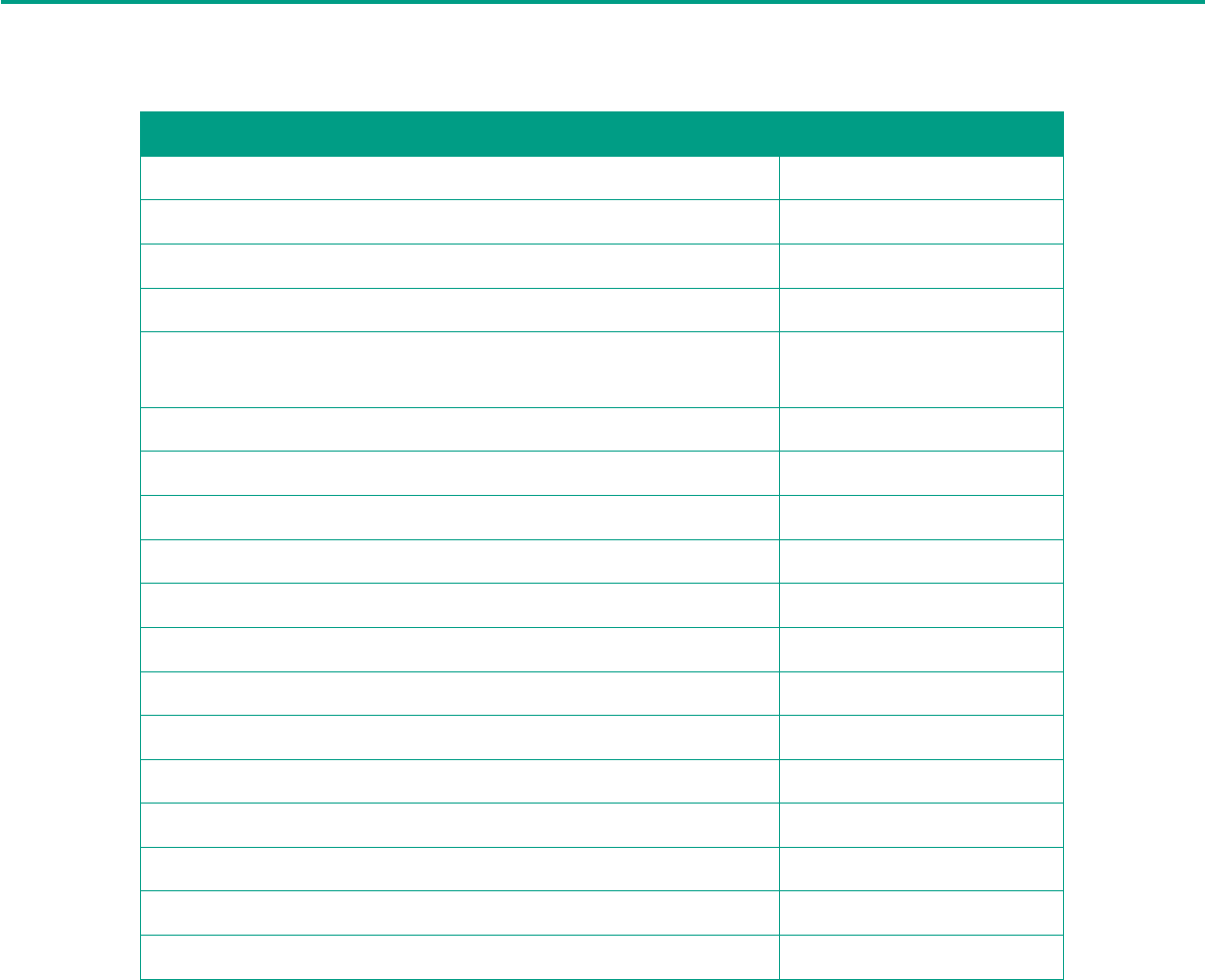

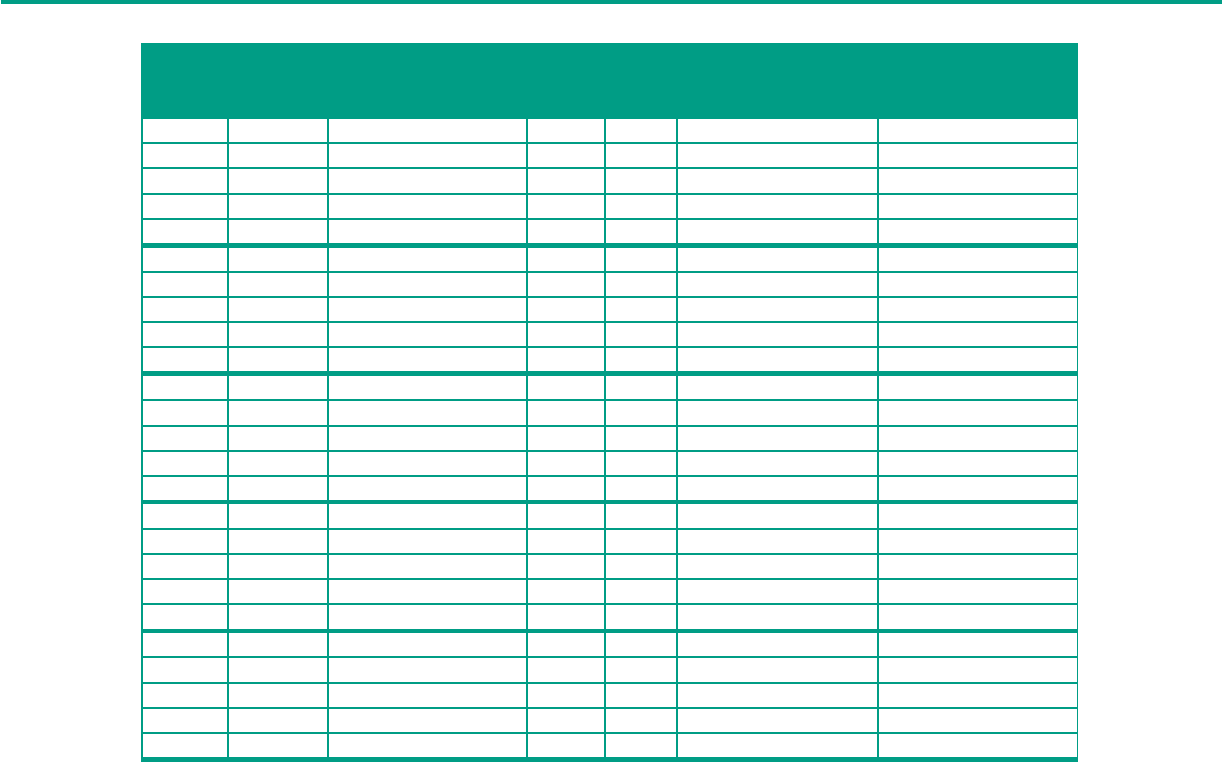

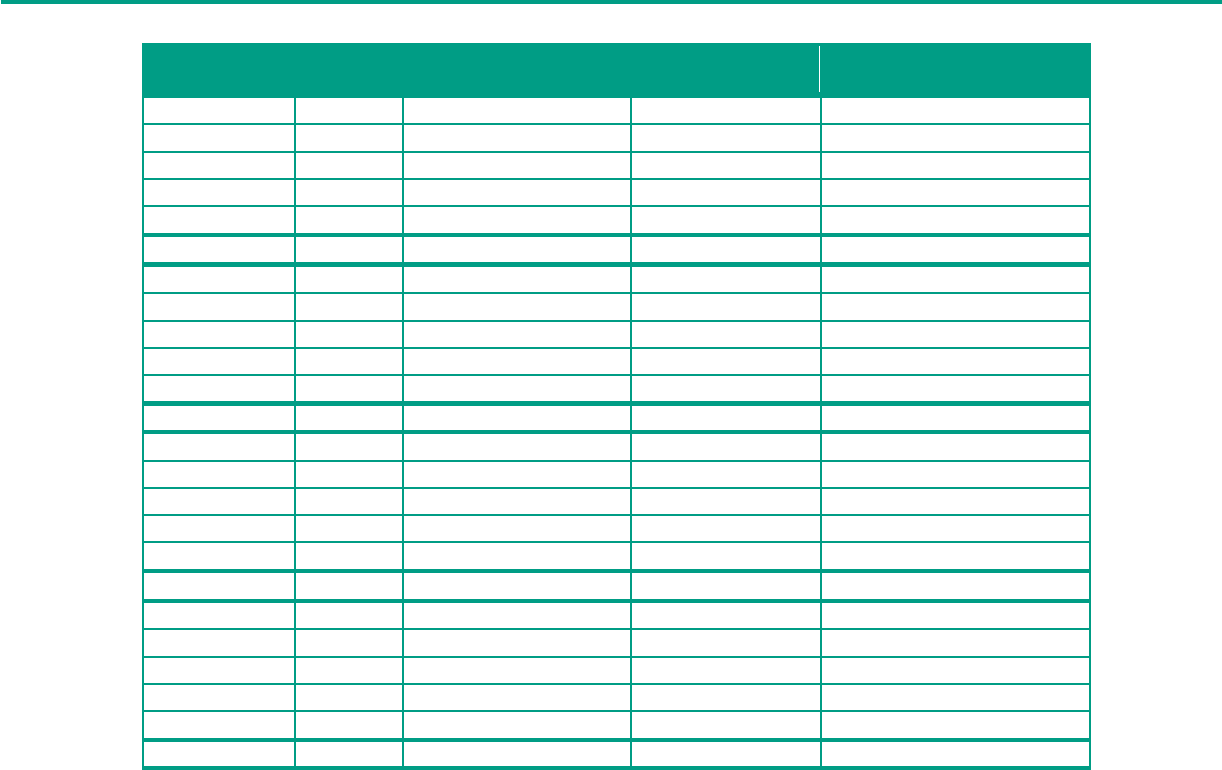

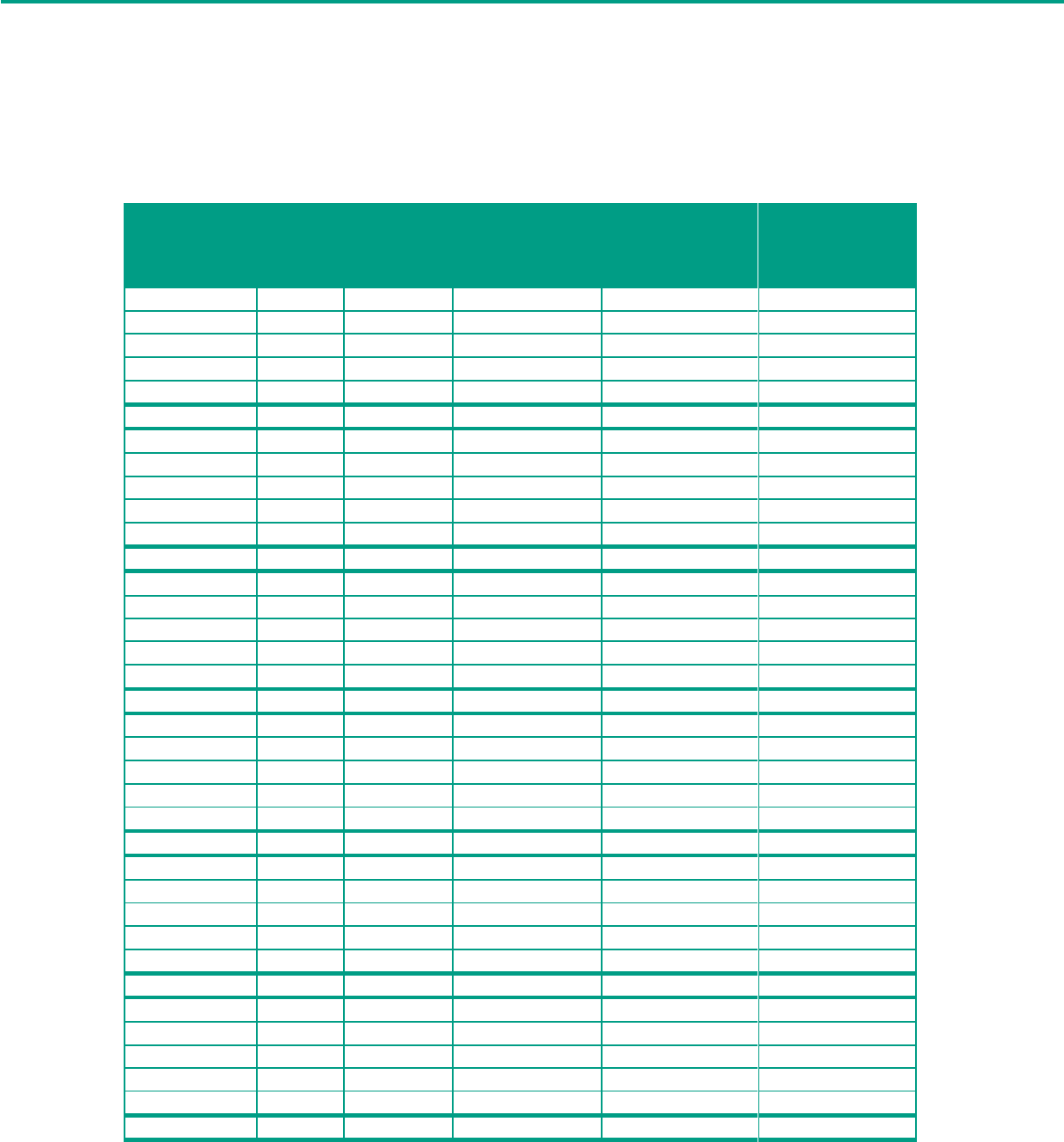

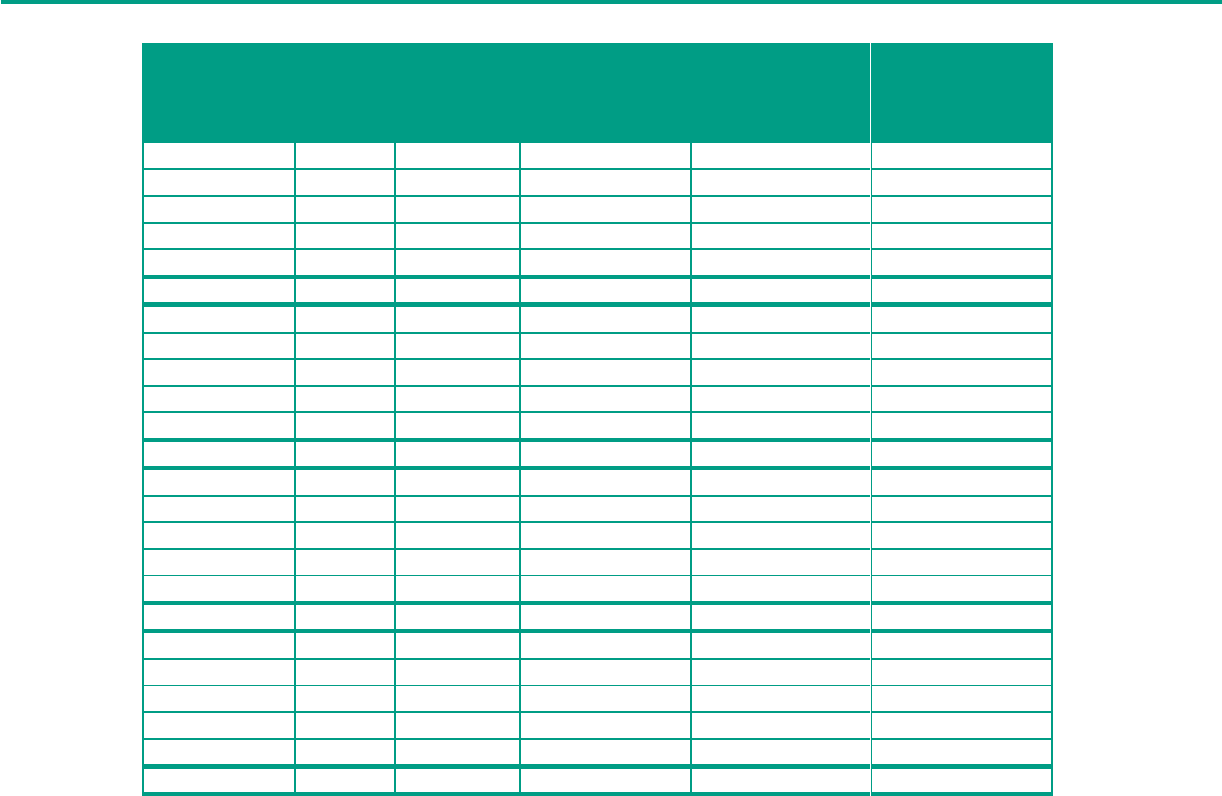

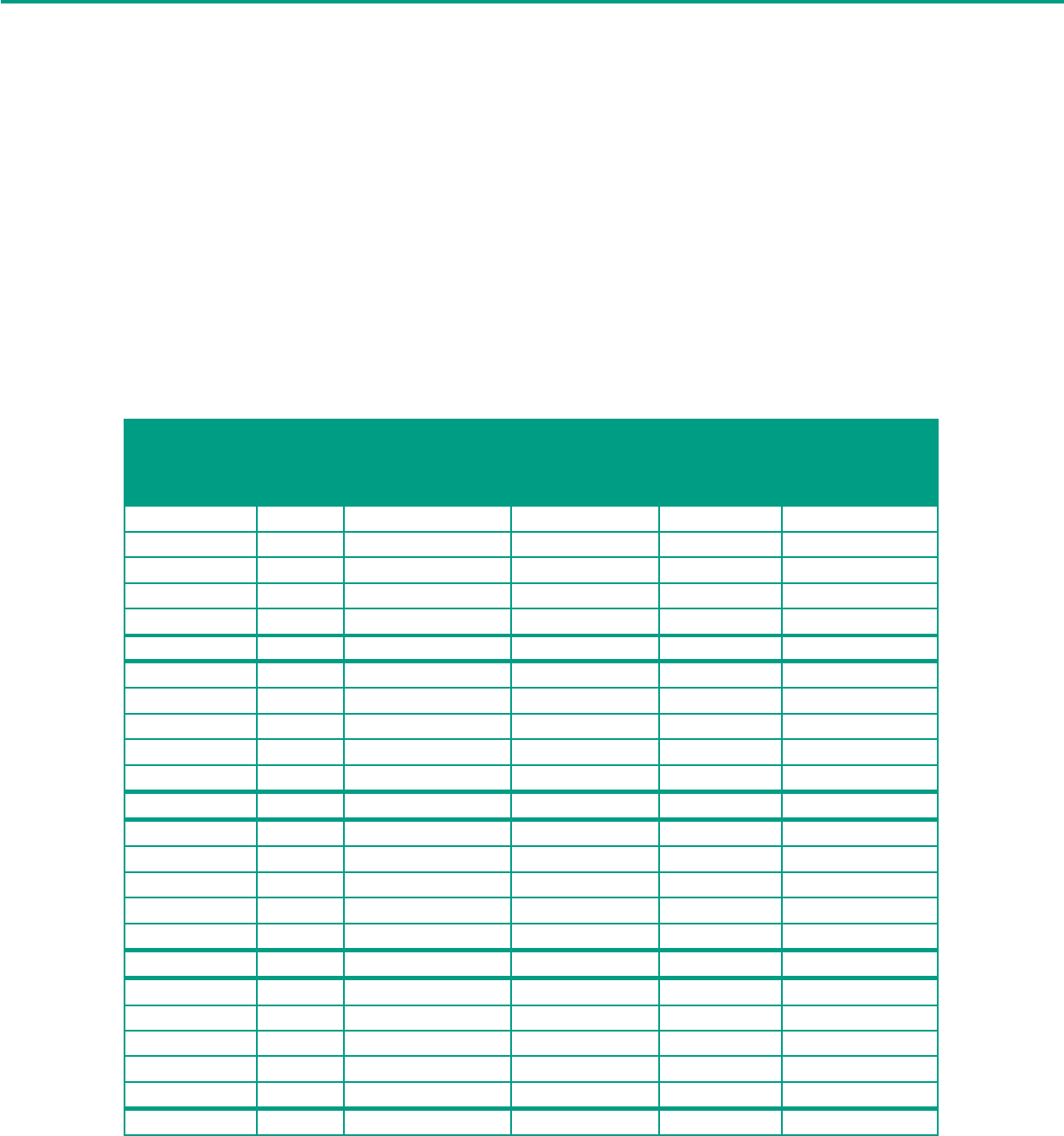

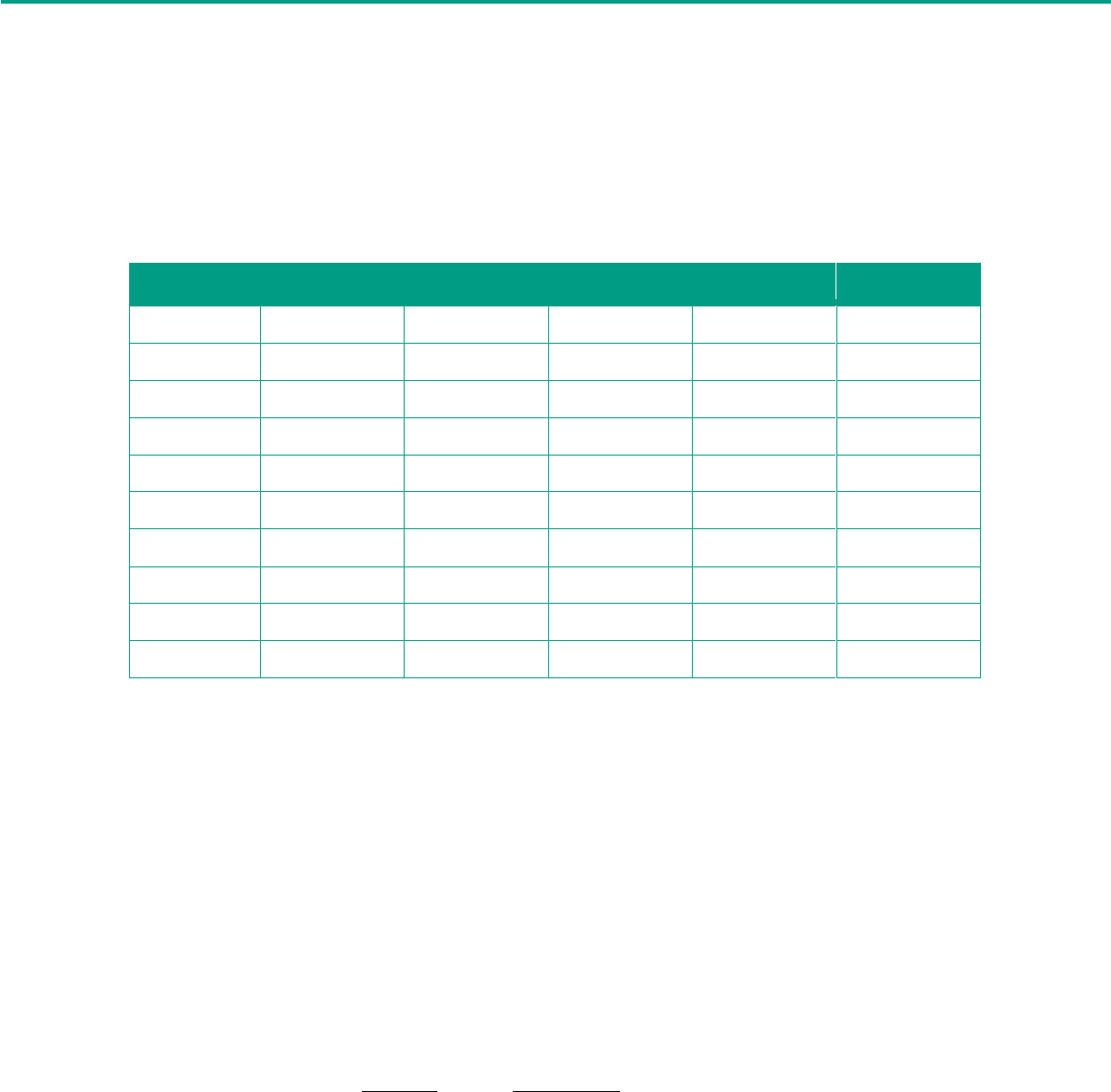

Table 1. Cost and benefit categories. ........................................................................................................... 4

Table 2. Comparison of economic appraisal measures. ........................................................................... 7

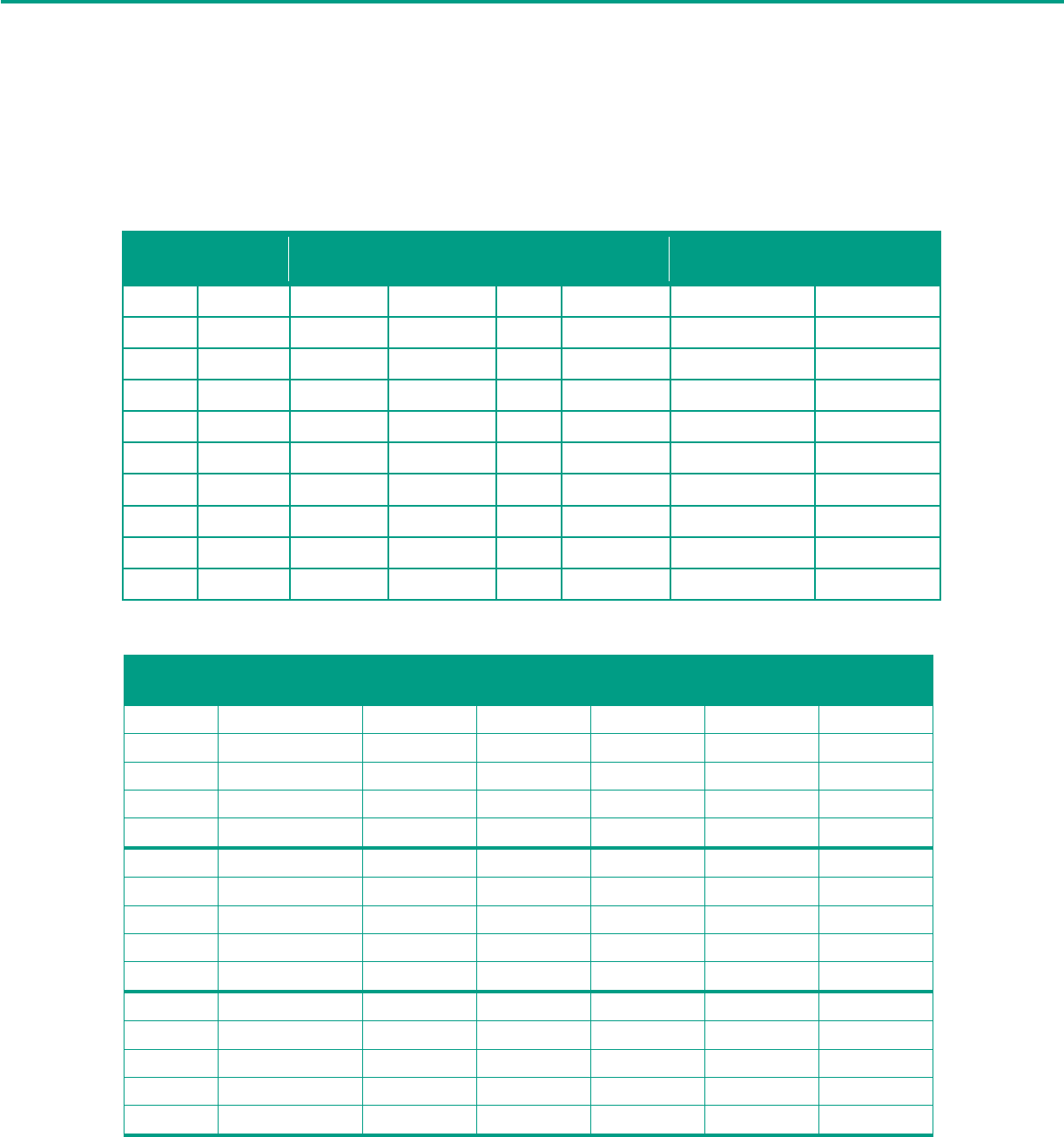

Table 3. Economic information for example project locations. .......................................................... 11

Table 4. BCR ranking of example project locations for Alternative 1. ............................................. 11

Table 5. NPV ranking of example project locations for Alternative 2. ............................................. 12

Table 6. Alternative 1 and Alternative 2 economic comparison. ....................................................... 12

Table 7. AIS injury codes.

(21)

........................................................................................................................ 27

Table 8. Frequently asked questions and answers for applying crash costs. .................................... 28

Table 9. Comprehensive crash costs (2017 U.S. $). .............................................................................. 30

Table 10. NHTSA recommended values of travel time (2017 U.S. $)

(11)

.......................................... 32

Table 11. TIGER recommended values of travel time by type (2017 U.S. $).

(23)

............................. 33

Table 12. TIGER recommended values of driver time (2017 U.S. $).

(23)

........................................... 33

Table 13. Reliability performance measures.

(27)

....................................................................................... 36

Table 14. Estimated value of net emissions per fatal crash (2017 dollars).

(11)

.................................. 42

Table 15. Estimated value of net emissions per injury crash (2017 dollars).

(11)

............................... 43

Table 16. Estimated value of net emissions per PDO crash (2017 dollars).

(11)

................................ 43

Table 17. Overview of methods to estimate safety performance of base condition. .................... 50

Table 18. Frequently asked questions and answers for applying crash costs. .................................. 56

Table 19. Example application of CMFs by severity. .............................................................................. 64

Table 20. Example application of crash costs by severity. .................................................................... 65

Table 21. Example of local severity distribution for total crashes...................................................... 66

Table 22. Example of combining CMFs. .................................................................................................... 70

Table 23. Example application of CMFs for multiple countermeasures. ........................................... 71

Table 24. Vehicle delay hours by crash severity and roadway type (per crash).

(11)

........................ 72

Table 25. Example monetization of travel time for a project on a rural principal arterial

(NHTSA methodology). ............................................................................................................................... 72

Table 26. Net increase in and cost of fuel consumption per fatal crash.

(11)

...................................... 75

Table 27. Net increase in and cost of fuel consumption per injury crash.

(11)

................................... 76

Table 28. Net increase in and cost of fuel consumption per PDO crash.

(11)

.................................... 76

Table 29. Example monetization of fuel-related vehicle operating cost for a project on a rural

principal arterial (NHTSA methodology). ................................................................................................ 77

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE

vii

Table 30. Example monetization of emissions for a project on a rural principal arterial (NHTSA

methodology).................................................................................................................................................. 78

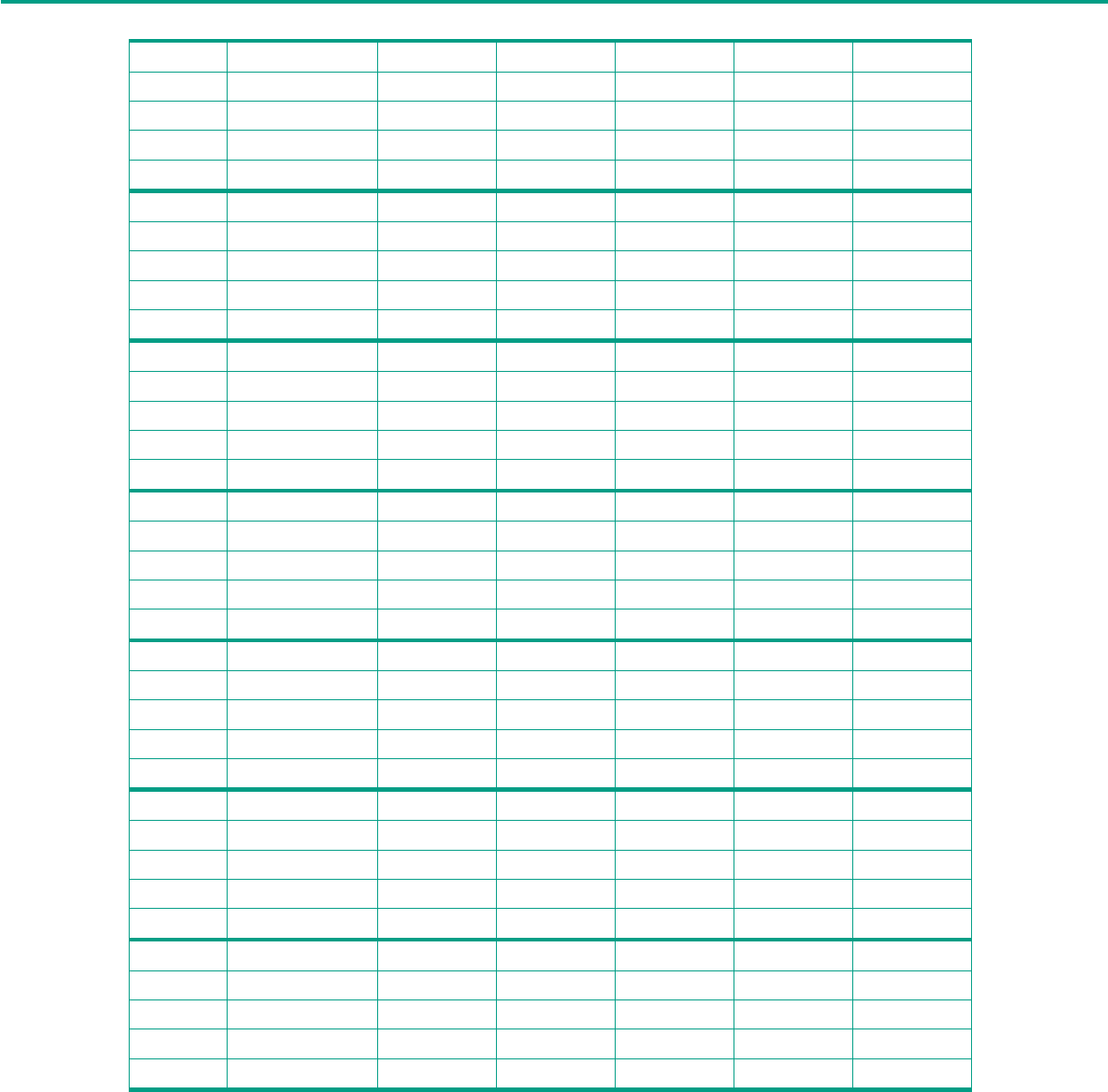

Table 31. Project costs for single countermeasure example, 2017 present value $. ..................... 81

Table 32. Amortization table for maintenance costs. ............................................................................ 82

Table 33. Estimated change in crashes by severity for alternative 1 (traffic signal). ....................... 83

Table 34. Estimated change in crashes by severity for alternative 2 (roundabout). ....................... 84

Table 35. Monetary safety benefit for alternative 1 (traffic signal). .................................................... 85

Table 36. Monetary safety benefit for alternative 2 (roundabout). .................................................... 85

Table 37. Monetary travel time benefit for alternative 1 (traffic signal). ........................................... 86

Table 38. Monetary travel time benefit for alternative 2 (roundabout). ........................................... 86

Table 39. Travel time reliability inputs for single countermeasure example. ................................... 87

Table 40. Monetary fuel-related benefit for alternative 1 (traffic signal)........................................... 88

Table 41. Monetary fuel-related benefit for alternative 2 (roundabout)........................................... 89

Table 42. Monetary emissions benefit for alternative 1 (traffic signal). ............................................. 90

Table 43. Monetary emissions benefit for alternative 2 (roundabout). ............................................. 90

Table 44. BCA results for single countermeasure example. ................................................................ 91

Table 45. Amortization table of project benefits for alternative 1 (traffic signal). .......................... 92

Table 46. Amortization table of project benefits for alternative 2 (roundabout). .......................... 93

Table 47. Project costs for multiple countermeasure example #1, 2017 present value $. .......... 94

Table 48. Estimated change in crashes by severity for multiple countermeasure example #1

(shoulder widening and shoulder rumble strips). ................................................................................... 96

Table 49. Monetary safety benefit for multiple countermeasure example #1 (shoulder widening

and shoulder rumble strips). ....................................................................................................................... 97

Table 50. Monetary travel time benefit for multiple countermeasure example #1 (shoulder

widening and shoulder rumble strips). ...................................................................................................... 98

Table 51. Travel time reliability inputs for multiple countermeasure example #1 (shoulder

widening and shoulder rumble strips). ...................................................................................................... 99

Table 52. Monetary fuel-related benefit for multiple countermeasure example #1 (shoulder

widening and shoulder rumble strips). .................................................................................................... 100

Table 53. Monetary emissions benefit for multiple countermeasure example #1 (shoulder

widening and shoulder rumble strips). .................................................................................................... 101

Table 54. BCA results for multiple countermeasure example #1. ................................................... 102

Table 55. Amortization table of project benefits for multiple countermeasure example #1

(shoulder widening and shoulder rumble strips). ................................................................................. 102

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE

viii

Table 56. Project costs for multiple countermeasure example #2 (shoulder widening and safety

edge), 2017 present value $. ..................................................................................................................... 103

Table 57. Estimated combined CMF by severity for multiple countermeasure example #2

(shoulder widening and safety edge). ...................................................................................................... 104

Table 58. Estimated change in crashes by severity for multiple countermeasure example #2

(shoulder widening and safety edge). ...................................................................................................... 106

Table 59. Monetary safety benefit for multiple countermeasure example #2 (shoulder widening

and safety edge). ........................................................................................................................................... 107

Table 60. Monetary travel time benefit for multiple countermeasure example #2 (shoulder

widening and safety edge). ......................................................................................................................... 108

Table 61. Monetary fuel-related benefit for multiple countermeasure example #2 (shoulder

widening and safety edge). ......................................................................................................................... 109

Table 62. Monetary emissions benefit for multiple countermeasure example #2 (shoulder

widening and safety edge). ......................................................................................................................... 110

Table 63. BCA results for multiple countermeasure example #2. ................................................... 111

Table 64. Amortization table of project benefits for multiple countermeasure example #2

(shoulder widening and safety edge). ...................................................................................................... 111

Table 65. Summary of curves for multiple sites example. .................................................................. 112

Table 66. Project cost for multiple sites example, 2017 present value $. ...................................... 113

Table 67. Estimated long-term average crashes for multiple sites example. .................................. 114

Table 68. Estimated crashes by severity for multiple sites example. ............................................... 115

Table 69. Estimated change in crashes by severity for multiple sites example. ............................. 116

Table 70. Monetary safety benefit for multiple sites example. .......................................................... 118

Table 71. Monetary travel time benefit for multiple sites example. ................................................. 120

Table 72. Monetary fuel-related benefit for multiple sites example................................................. 122

Table 73. Monetary emissions benefit for multiple sites example. ................................................... 124

Table 74. Summary of annual monetary benefits for multiple sites example. ................................ 126

Table 75. BCA results for multiple sites example. ............................................................................... 127

Table 76. Amortization table of project benefits for multiple sites example. ................................ 127

Table 77. BCA results for multiple sites example. ............................................................................... 137

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE

ix

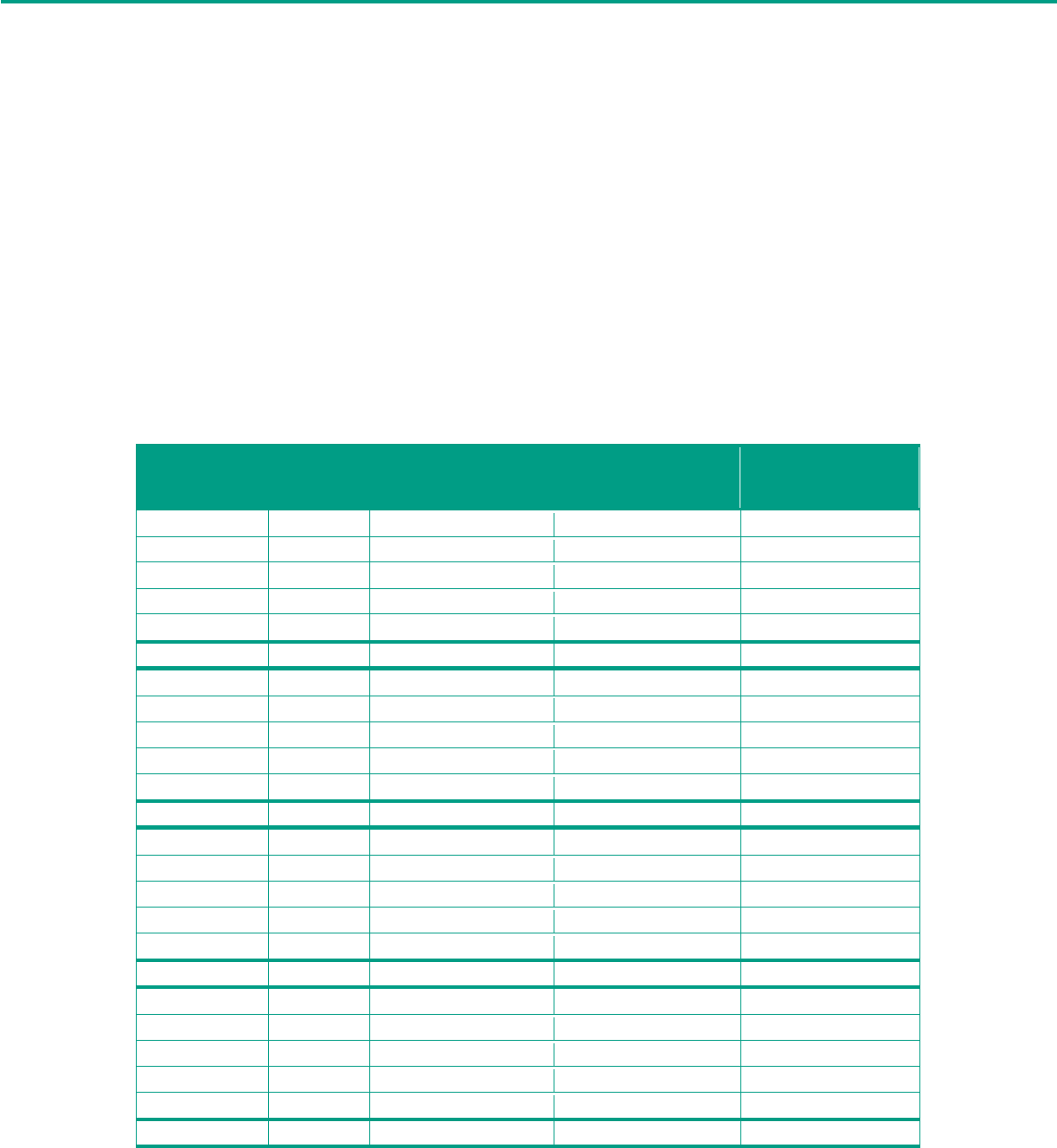

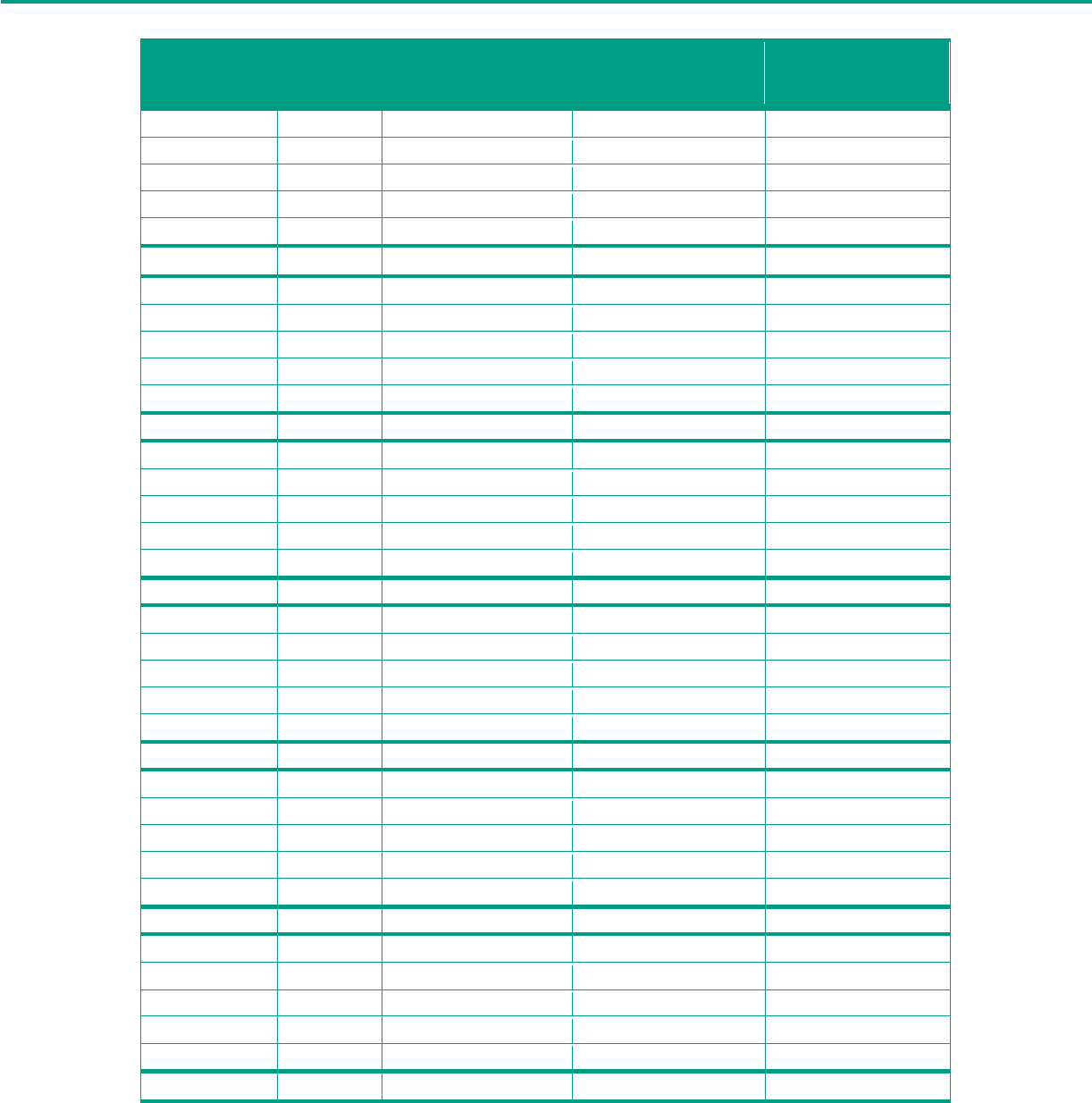

LIST OF FIGURES

Figure 1. Chart. Roadway safety management process. ........................................................................... 6

Figure 2. Equation. Cost-effectiveness index. ............................................................................................. 8

Figure 3. Equation. Benefit-cost ratio. .......................................................................................................... 8

Figure 4. Equation. Net present value. ......................................................................................................... 9

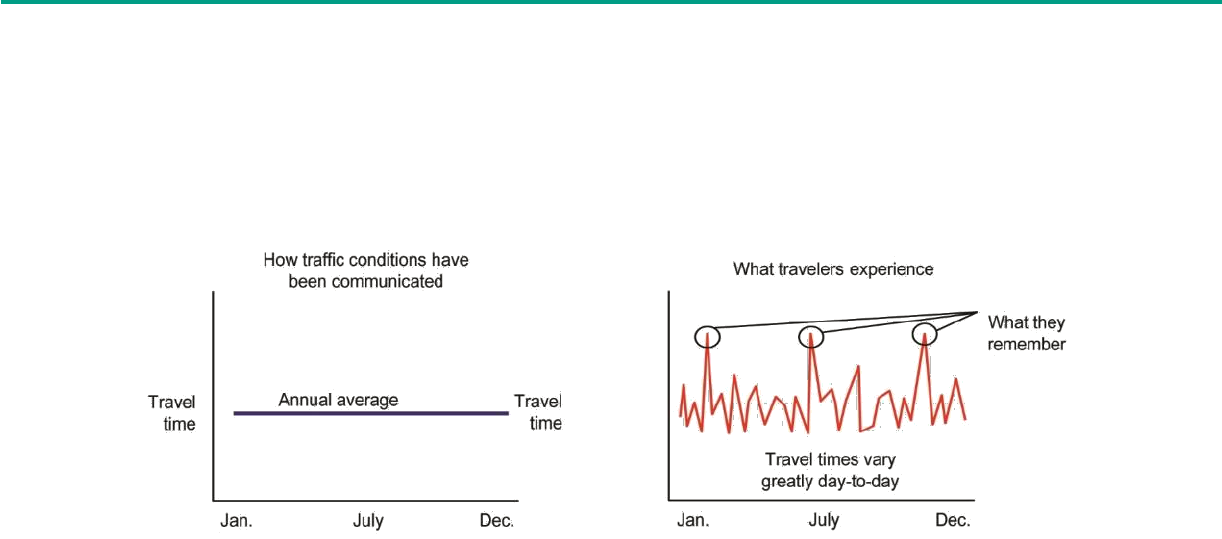

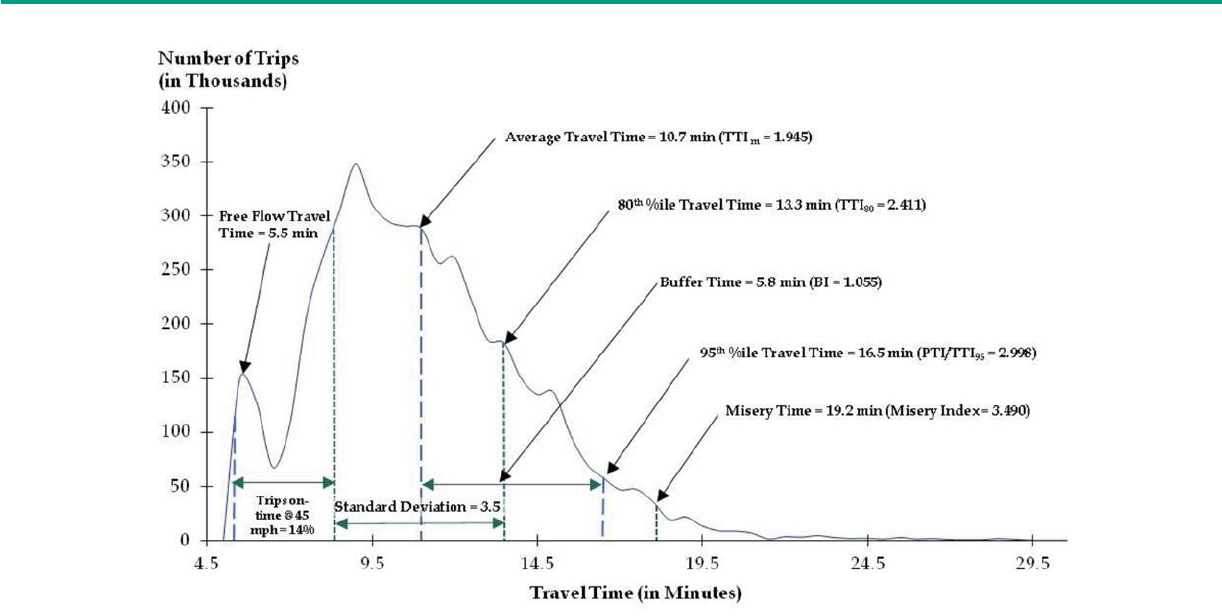

Figure 5. Chart. Recurring travel time measurement versus actual traveler experience.

(26)

........ 35

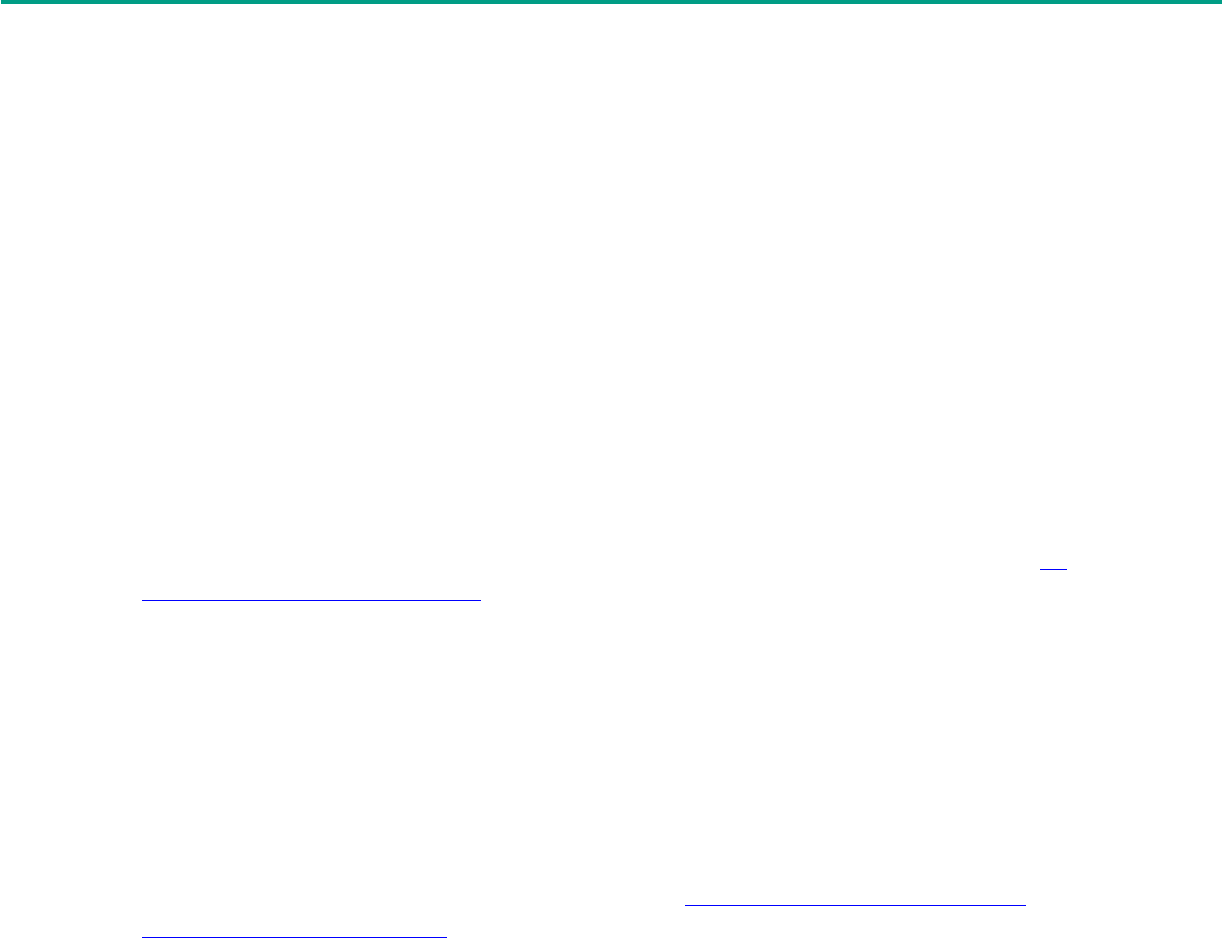

Figure 6. Chart. Relationship of travel time measures and reliability.

(28)

........................................... 37

Figure 7. Equation. Example SPF. ................................................................................................................ 48

Figure 8. Chart. Time series of costs and benefits (in constant dollars).

(8)

....................................... 53

Figure 9. Equation. Standard formula for discounting. .......................................................................... 54

Figure 10. Equation. Discount factor. ........................................................................................................ 54

Figure 11. Equation. Summation of discounted values. ......................................................................... 55

Figure 12. Equation. Estimating crashes for a single countermeasure. .............................................. 63

Figure 13. Equation. Additive method for estimating the combined benefit of multiple

countermeasures. .......................................................................................................................................... 67

Figure 14. Equation. Dominant common residuals method for estimating the combined benefit

of multiple countermeasures. ..................................................................................................................... 68

Figure 15. Equation. Multiplicative method for estimating the combined benefit of multiple

countermeasures. .......................................................................................................................................... 68

Figure 16. Equation. Example conversion of annual cost to present value cost for year 21

(Alternative 1). ............................................................................................................................................... 81

Figure 17. Equation. Example conversion of annual safety benefit to present value benefit for

year 21 (alternative 1)................................................................................................................................... 91

Figure 18. Equation. Example conversion of annual safety benefit to present value benefit for

year 8 (multiple countermeasure example #1). .................................................................................... 101

Figure 19. Equation. Dominant common residuals method for estimating the combined effect of

shoulder widening and safety edge on KABC crashes. ....................................................................... 105

Figure 20. Equation. Dominant common residuals method for estimating the combined effect of

shoulder widening and safety edge on PDO crashes........................................................................... 105

Figure 21. Equation. Example conversion of annual safety benefit to present value benefit for

year 7 (multiple countermeasure example #2). .................................................................................... 110

Figure 22. Equation. SPF for rural, two-lane base segments. ............................................................. 113

Figure 23. Equation. CMF for horizontal curve on rural, two-lane road. ....................................... 114

Figure 24. Equation. Example conversion of annual safety benefit to present value benefit for

curve 1 in year 5 (multiple sites example). ............................................................................................ 126

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE

x

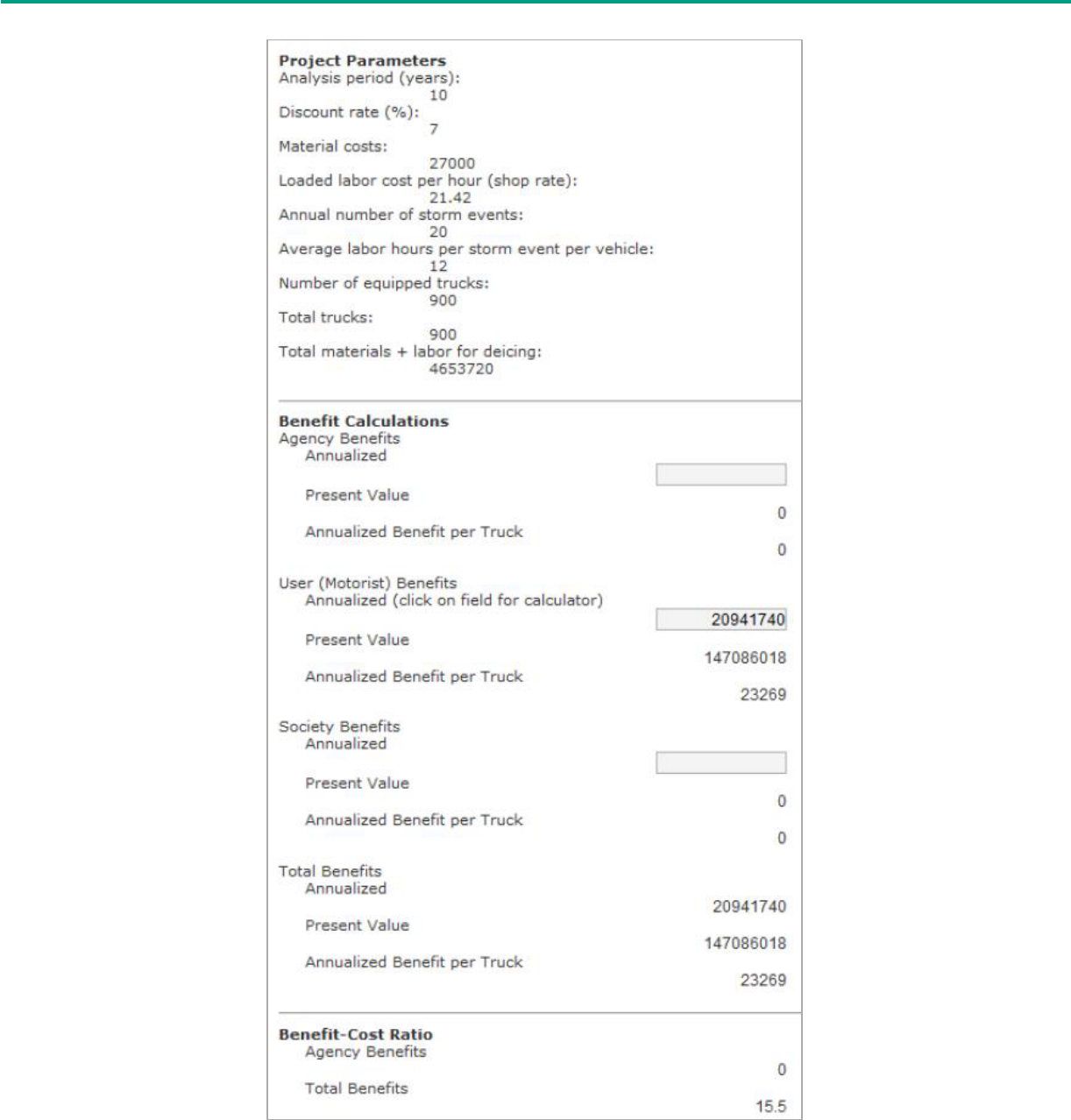

Figure 25. Chart. Tabular and graphical BCA results from Highway Safety BCA Tool. .............. 131

Figure 26. Chart. Tabular BCA results from TOPS-BC tool.

(37)

........................................................ 132

Figure 27. Chart. Tabular BCA results from Clear Roads cost-benefit tool.

(38)

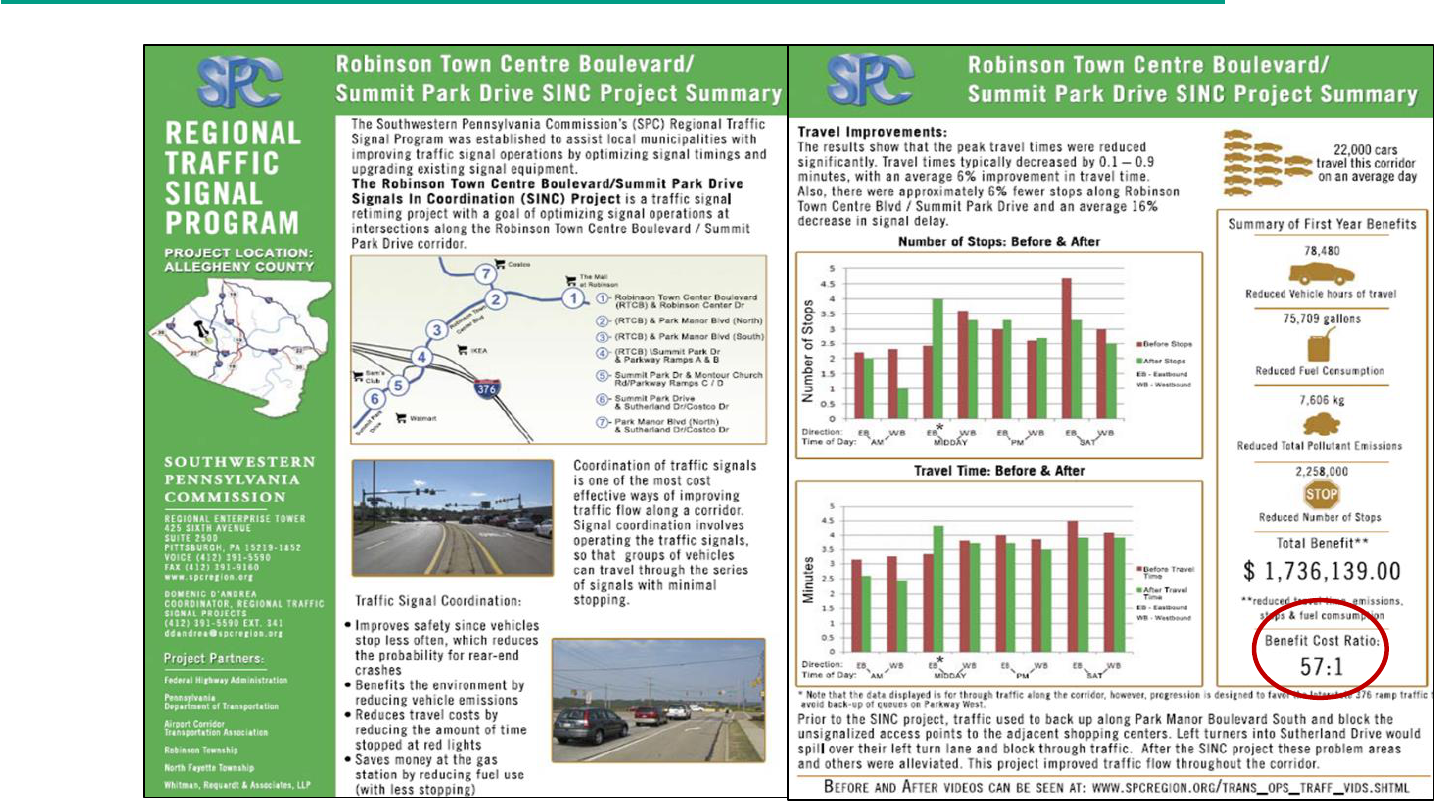

............................ 133

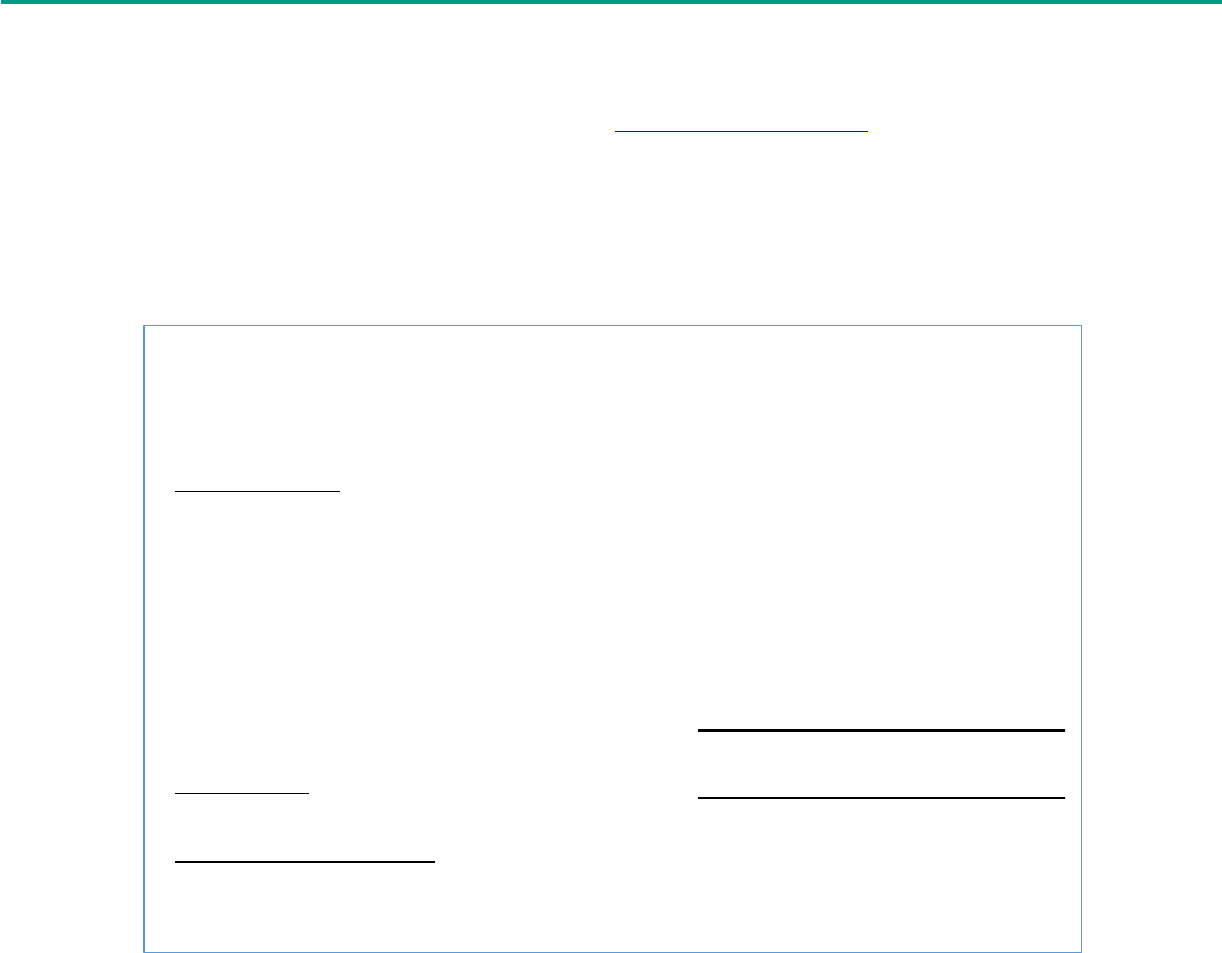

Figure 28. Chart. Graphical BCA results from Kansas City SCOUT.

(39)

......................................... 134

Figure 29. Chart. Newsletter display of BCA results from Southwestern Pennsylvania Regional

Signal Program.

(9)

.......................................................................................................................................... 135

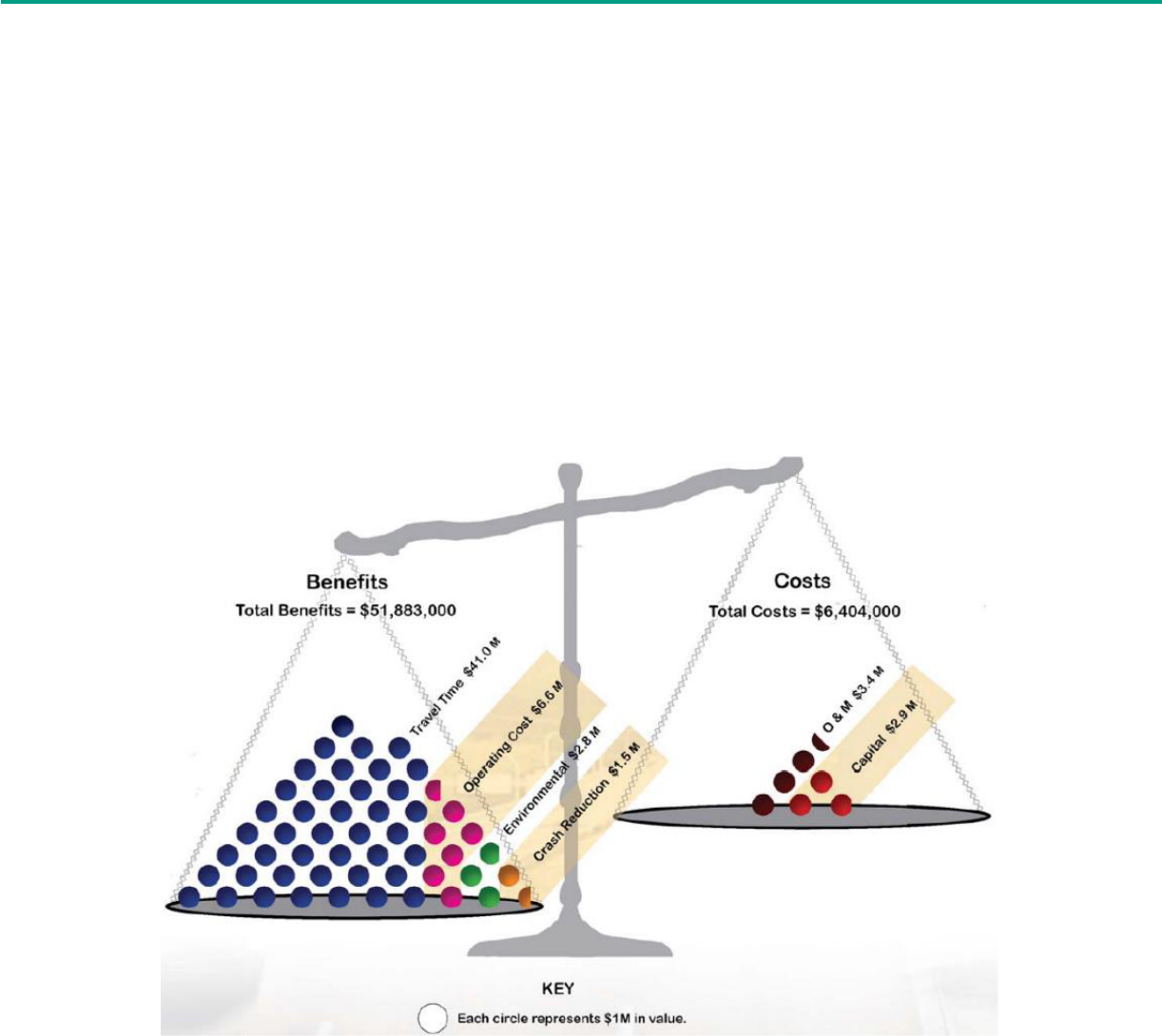

Figure 30. Chart. Multidimensional graphical BCA results from the Metropolitan Transportation

Commission.

(9)

.............................................................................................................................................. 136

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE

xi

ACRONYMS

AADT Annual Average Daily Traffic

AIS Abbreviated Injury Scale

BCA Benefit-Cost Analysis

BCR Benefit-Cost Ratio

CFR Code of Federal Regulations

CMAQ Congestion Mitigation and Air Quality

CMF Crash Modification Factor

EA Environmental Assessment

EIS Environmental Impact Statement

EPA Environmental Protection Agency

FHWA Federal Highway Administration

HSIP Highway Safety Improvement Program

KABCO National Safety Council Injury Scale

LCCA Life-Cycle Cost Analysis

MMUCC Model Minimum Uniform Crash Criteria

MPO Metropolitan Planning Organization

NCHRP National Cooperative Highway Research Program

NEPA National Environmental Policy Act

NHTSA National Highway Traffic Safety Administration

NPV Net Present Value

OMB Office of Management and Budget

PDO Property Damage Only

PHT Person Hours of Travel

SHRP2 Second Strategic Highway Research Program

SPF Safety Performance Function

TAC Technical Advisory Committee

TRB Transportation Research Board

USDOT United States Department of Transportation

VMT Vehicle Miles Traveled

VOC Volatile Organic Compound

VSL Value of a Statistical Life

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE

xii

EXECUTIVE SUMMARY

Transportation agencies must continuously justify the economic effectiveness of their programs

and expenditures. Economically effective and efficient projects are particularly important for

safety programs that establish aggressive targets and require greater fiscal responsibility and

stewardship to achieve these goals. Further, transportation professionals routinely assess and

prioritize projects based on costs and benefits related to pavement preservation, operational

performance, and environmental impacts. While guidance and tools are available to analyze the

direct safety-related benefits and costs of projects, there is a need to consider the complete

lifecycle cost and benefits of all projects, including the indirect safety-related benefits.

There are many reasons to perform a benefit-cost analysis (BCA) for transportation projects.

Some funding programs require BCA (e.g., TIGER and INFRA grants), while other agencies

establish a policy or procedure to perform BCA. In either case, the following are specific

benefits to employing BCA in the roadway safety management and project development

processes:

• Best Return on Investment: Economic analysis can help in planning, programming,

and implementing transportation programs with the best rate of return for any given

budget. It can also help to determine an optimal program budget.

• Cost-Effective Design and Construction: Economic analysis can inform agencies as

to which of several project designs to implement at the lowest lifecycle cost to the

agency, lowest delay cost to the traveler, highest safety benefit to users, and the best

affordable balance between these costs.

• Understanding Complex Projects: In a time of growing public scrutiny of new and

costly road projects, transportation agencies and other decision makers need to

understand the comprehensive costs and benefits of these projects. A rigorous BCA can

help to quantify and compare the impacts of project alternatives on safety, mobility, the

environment, and regional economies.

• Documentation of Decision Process: The discipline of quantifying and valuing the

benefits and costs of highway projects also provides documentation to justify and

explain the decision process to legislatures and the public.

The Highway Safety Benefit-Cost Analysis Guide provides agencies with the knowledge, tools,

and insights to perform reliable highway safety BCA and communicate the results. For those

new to BCA, this Guide introduces the BCA process and describes fundamental concepts and

factors to consider when preparing for BCA. For those familiar with BCA, this Guide can help

to enhance current practices through a discussion of common challenges and opportunities to

overcome those challenges. This Guide also defines typical project costs and benefits included

in BCA and provides default values to monetize these benefits. This Guide provides instruction

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE

xiii

and examples of how to estimate and monetize safety-related project benefits, including the

expected change in crashes and the resulting operational and environmental benefits. Finally,

this Guide provides considerations and examples related to the communication of BCA results.

In summary, BCA is critical to understanding the potential return on investment from potential

projects and programs. While BCA is a policy or procedural decision, this Guide can help

agencies to understand the value of performing BCA, consider the data requirements and

resources to perform BCA, and determine the specific format and parameters of the analysis.

This Guide can also help transportation professionals perform reliable BCA and use the results

to inform decisions and improve investments.

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE CHAPTER 1

1

1. OVERVIEW OF GUIDE

1.1 INTRODUCTION AND PURPOSE

This Guide focuses on the safety benefits of competing engineering projects (i.e., expected

difference in crash frequency and severity) and the benefits derived from differences in safety

performance (e.g., reduced delay, travel time, and emissions because of fewer crashes). While

safety is a key factor in transportation decision-making, agencies may consider many factors in

project selection and programming. The following is a list of other potential factors an agency

may consider during project selection and programming:

• Other planned projects at the location (for safety improvement or otherwise).

• Right-of-way needs and acquisition.

• Operational efficiency.

• Environmental impacts and mitigation.

• Economic impacts.

• Social equity (distribution of investments across select population groups).

• Project readiness.

• Familiarity with the treatment’s design, construction, and potential impacts.

• Public requests for improvement projects.

• Public acceptance and perception.

This Guide explains how to quantify the monetary benefits associated with expected differences

in safety among project alternatives, and the indirect operational and environmental benefits

(i.e., operational and environmental impacts that result from a change in safety performance). It

focuses on project-level analysis of single or multiple improvements at a given location. It also

covers network-level analysis for projects that include multiple locations (e.g., systemic

improvements). This Guide focuses on economic analysis and only briefly discusses project

prioritization within a program. It does not address behavioral measures or the direct benefits

related to operations and the environment (i.e., those benefits not derived from a change in

safety performance). Agencies may use other methods and tools to quantify the benefits of

behavioral measures and non-safety factors (e.g., microsimulation to estimate operational

impacts; noise and emissions models to estimate environmental impacts). Some of these non-

safety factors (e.g., public acceptance) may be difficult to quantify and will require subjective

weights to prioritize projects.

While this Guide provides methods and default values to monetize the direct and indirect

safety benefits of alternatives, a benefit-cost analysis (BCA) is a policy or procedural decision

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE CHAPTER 1

2

where an agency defines the parameters. Agencies should develop a prioritization process that

meets their specific needs, integrating quantitative safety and non-safety factors as needed.

A BCA is a policy or procedural decision where an

agency defines the parameters.

1.2 TARGET AUDIENCE

This Guide is intended to meet the needs of transportation professionals conducting highway

safety BCA for projects and programs. Transportation professionals, such as traffic and safety

engineers or planners, are the target audience for this Guide. This Guide assumes these

professionals are not economists and may not have formal training in economic evaluation

techniques. Thus, this Guide describes basic concepts and terminology relating to BCA to

support the needs of transportation professionals who may be new to BCA.

1.3 STRUCTURE OF THE GUIDE

This Guide is organized into nine chapters and an appendix. Chapter 2 introduces fundamental

concepts of BCA and safety management, defines economic measures for BCA, provides an

overview of BCA in the safety management and project development process, and identifies

several related resources. Chapter 3 introduces project costs, including the costs to design,

construct, operate, maintain, and rehabilitate the project. Chapter 4 introduces project

benefits, identifying types of benefits included in highway safety BCA and default values to

monetize benefits. Chapter 5 identifies factors to consider when preparing for BCA such as the

base condition, analysis period, potential for uncertainty in the underlying data and analysis

results, and discount rate. Chapter 6 describes how to estimate and monetize safety-related

project benefits, including the expected change in crashes and the resulting change in

operational and environmental measures. Chapter 7 presents hypothetical examples of BCA for

projects with single countermeasures, multiple countermeasures, and multiple locations.

Chapter 8 presents considerations and options for communicating BCA results to decision-

makers. Chapter 9 presents a summary of this Guide with key takeaways. Appendix A provides

a glossary of terms.

Complementary to this Guide, a spreadsheet-based BCA tool was developed to complete a

BCA in accordance with the methods, assumptions, and data sources described in this Guide.

The purpose of the Tool is to assist transportation professionals in generating results for

presentation to colleagues, management, and the public. The Tool provides the framework for

an efficient and repeatable process that facilitates communication of the results to diverse

audiences.

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE CHAPTER 2

3

2. OVERVIEW OF BCA FOR SAFETY

A BCA is a key component of a comprehensive project or program development process that

considers quantitative and qualitative impacts of highway investments. Transportation agencies

use these economic evaluation techniques to identify, quantify, and assign value to the economic

benefits and costs of highway projects and programs over multiyear timeframes. This chapter

introduces fundamental concepts of BCA and the safety management process, defines economic

measures for BCA, provides an overview of BCA in the safety management process and project

development process, and identifies several related resources.

Chapter 2 At-A-Glance

Chapter 2 is divided into six sections:

• Section 2.1 defines BCA.

• Section 2.2 defines safety management, including the crash-based approach, the systemic

approach, and how these two complementary approaches provide a comprehensive

approach to safety management.

• Section 2.3 introduces economic measures used to compare and rank alternatives,

including present value cost (PVC), present value benefit (PVB), benefit-cost ratio

(BCR), net present value (NPV), cost-effectiveness index (CEI), and payback period.

• Section 2.4 describes the use of BCA in safety management, including the use of BCA to

achieve the most efficient or effective project.

• Section 2.5 provides a brief description of several highway safety BCA resources.

• Section 2.6 provides a summary of the chapter.

2.1 WHAT IS BENEFIT-COST ANALYSIS?

A BCA is a systematic process for calculating and comparing the benefits and costs of project

alternatives.

(1)

A BCA attempts to capture all benefits to society from a project or course of

action, and the cost to achieve those benefits, regardless of which party realizes the benefits

and costs, or the form of these benefits and costs. Using BCA, transportation professionals can

compare present value costs and benefits among alternatives for a given analysis period. Used

properly, BCA reveals the most economically-efficient investment alternative (i.e., the one that

maximizes the net benefits to society relative to the allocation of resources).

A BCA is systematic process for calculating and

comparing benefits and costs of a project.

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE CHAPTER 2

4

A BCA differentiates costs and benefits by project costs (or agency costs), project benefits (or

user benefits), and externalities (or non-user benefits). Project benefits and externalities include

costs avoided, but also include negative benefits (disbenefits) such as increased crashes or air

emissions. Analysts monetize project benefits by assigning dollar values to the different effects.

For example, if there is an expected change in crash frequency associated with a project

alternative, compared to the base condition (e.g., the do-nothing alternative), then the analyst

multiplies the expected change in crashes by the average cost of a crash. If there are negative

impacts, then these appear as negative benefits. Table 1 summarizes common project costs,

project benefits, and externalities.

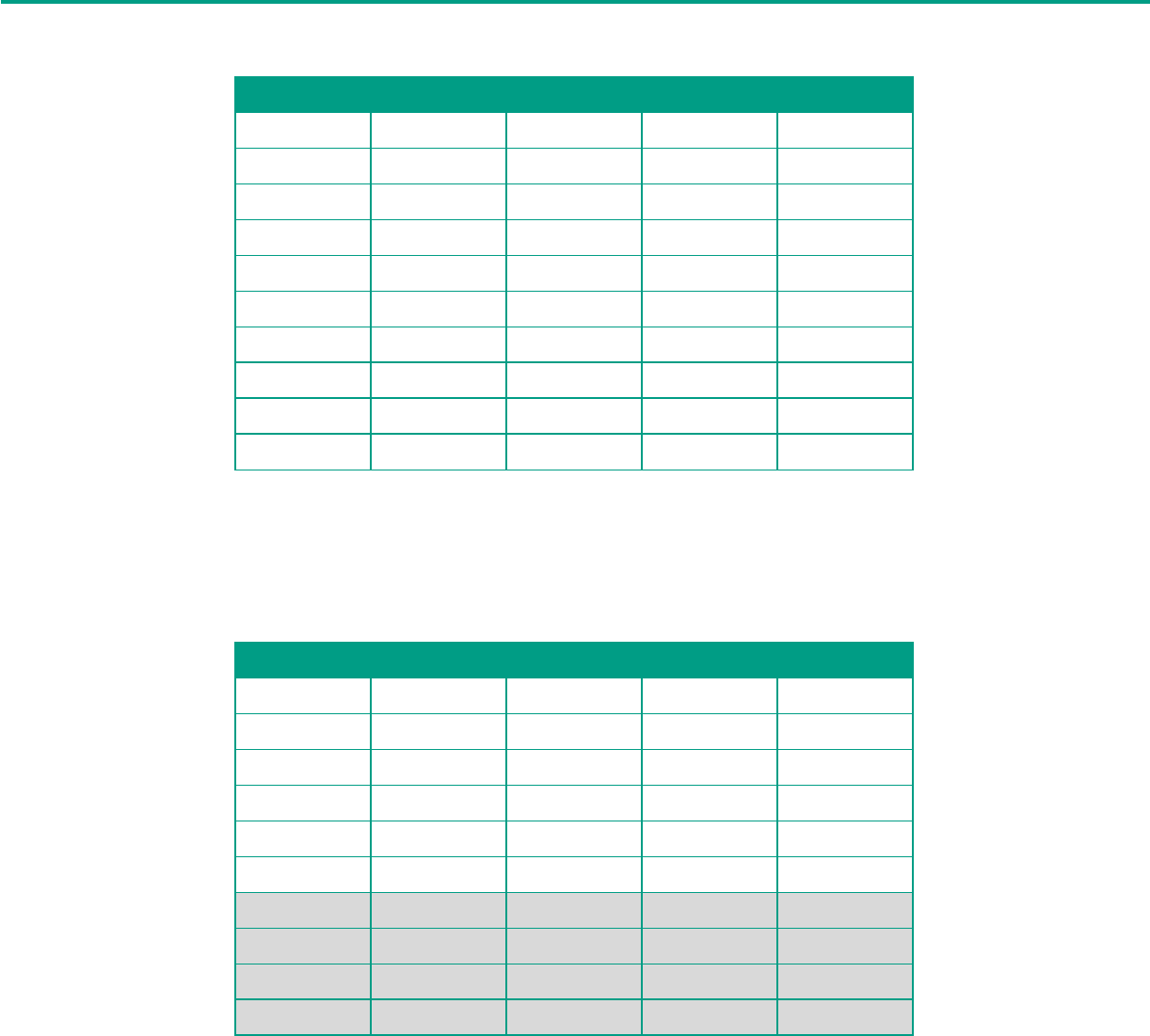

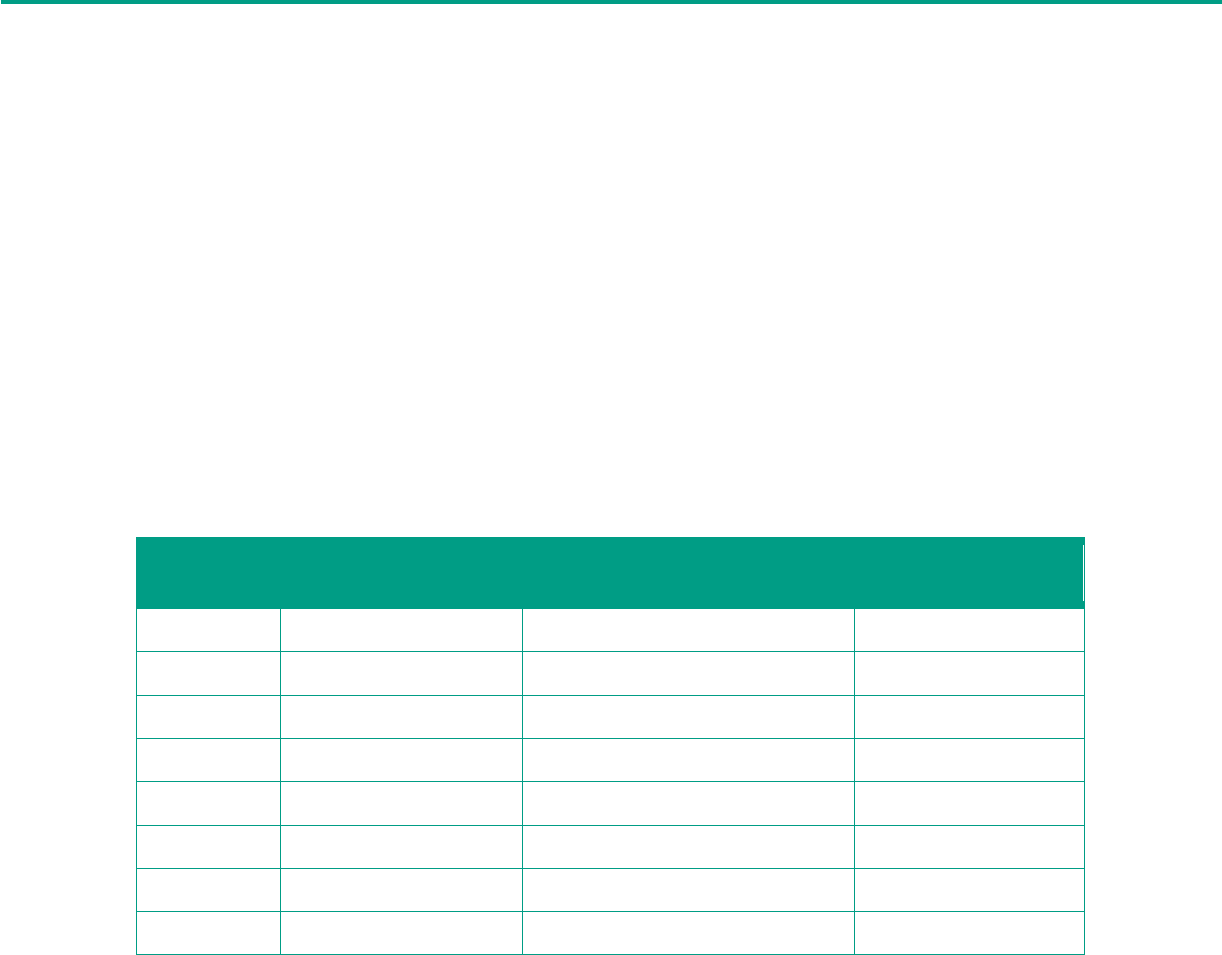

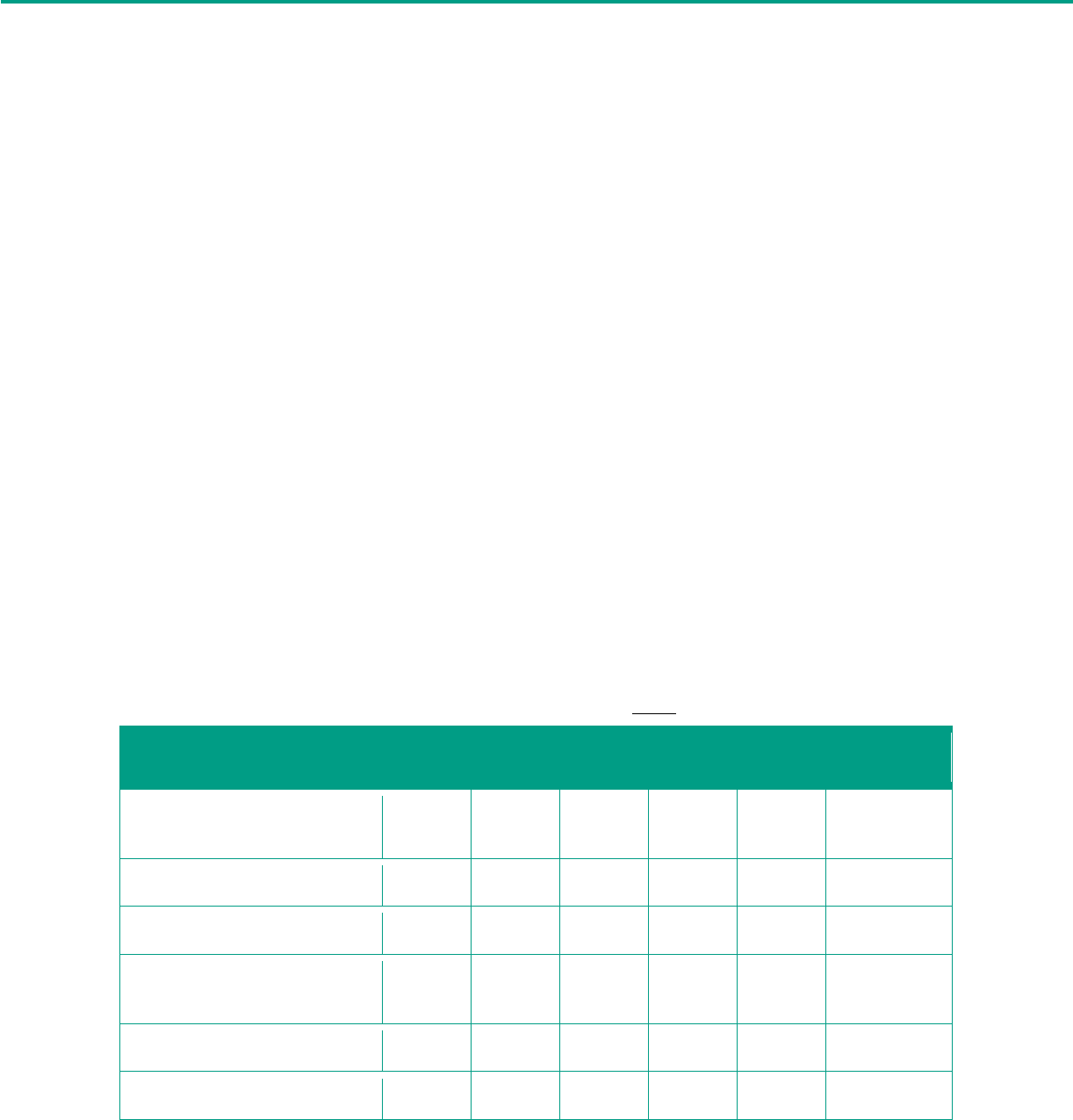

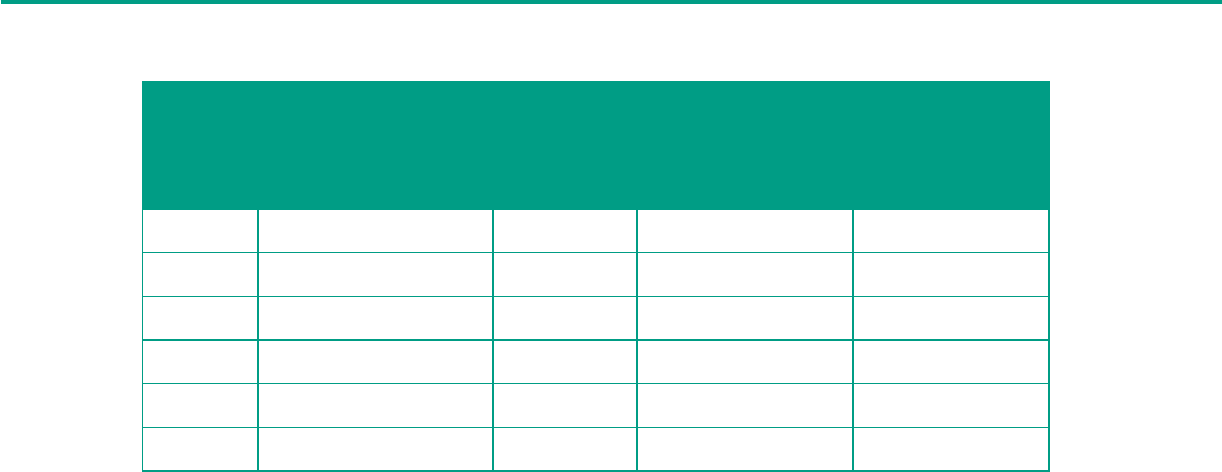

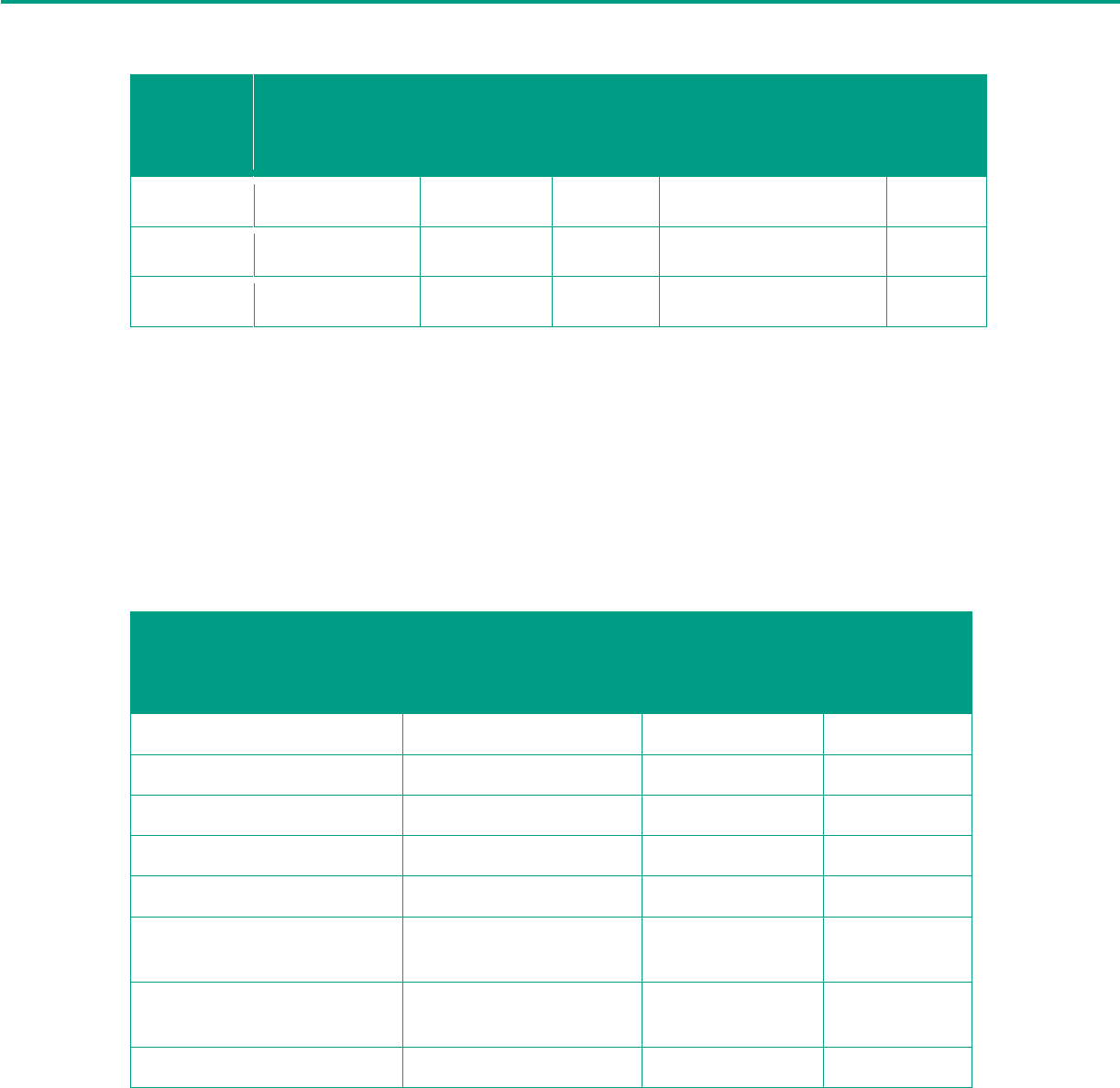

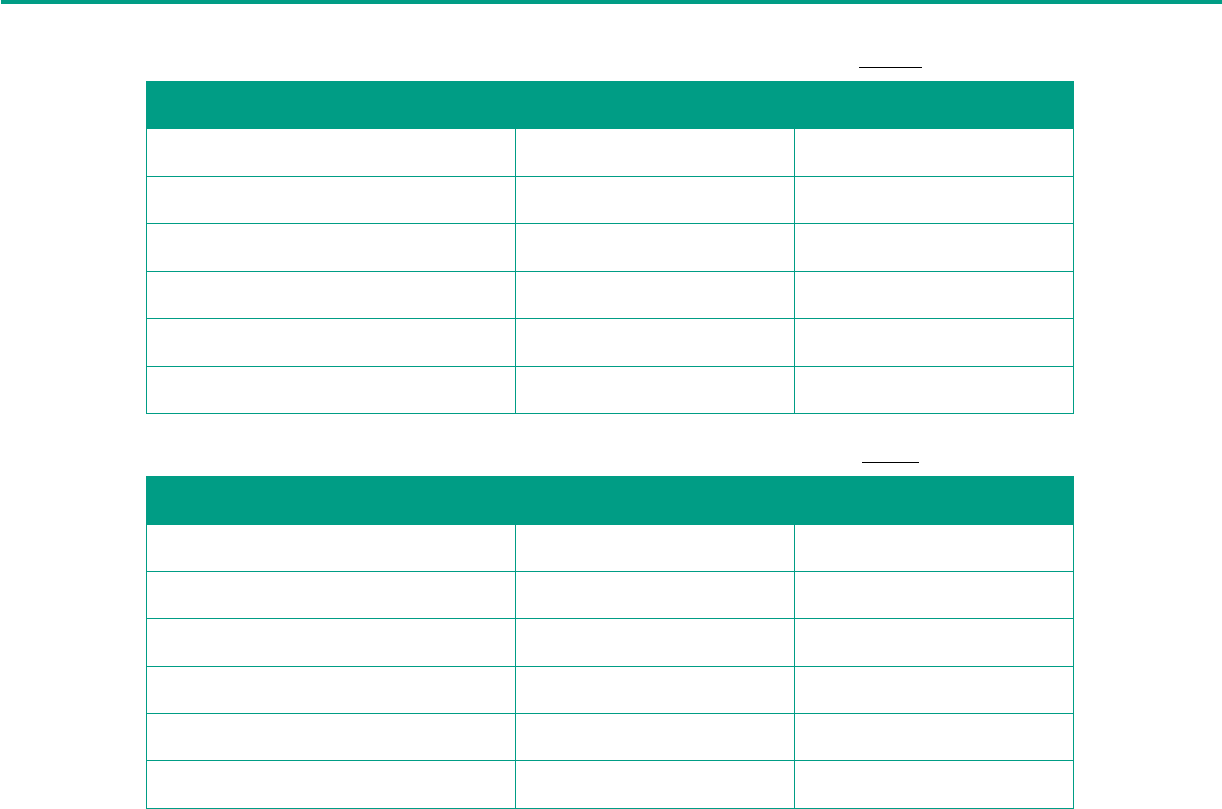

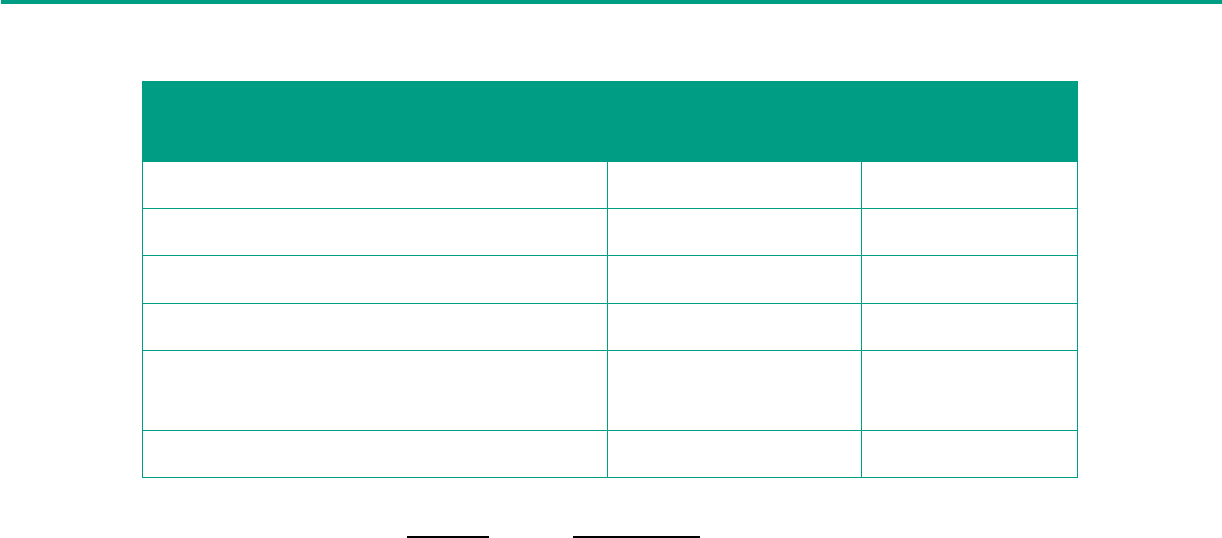

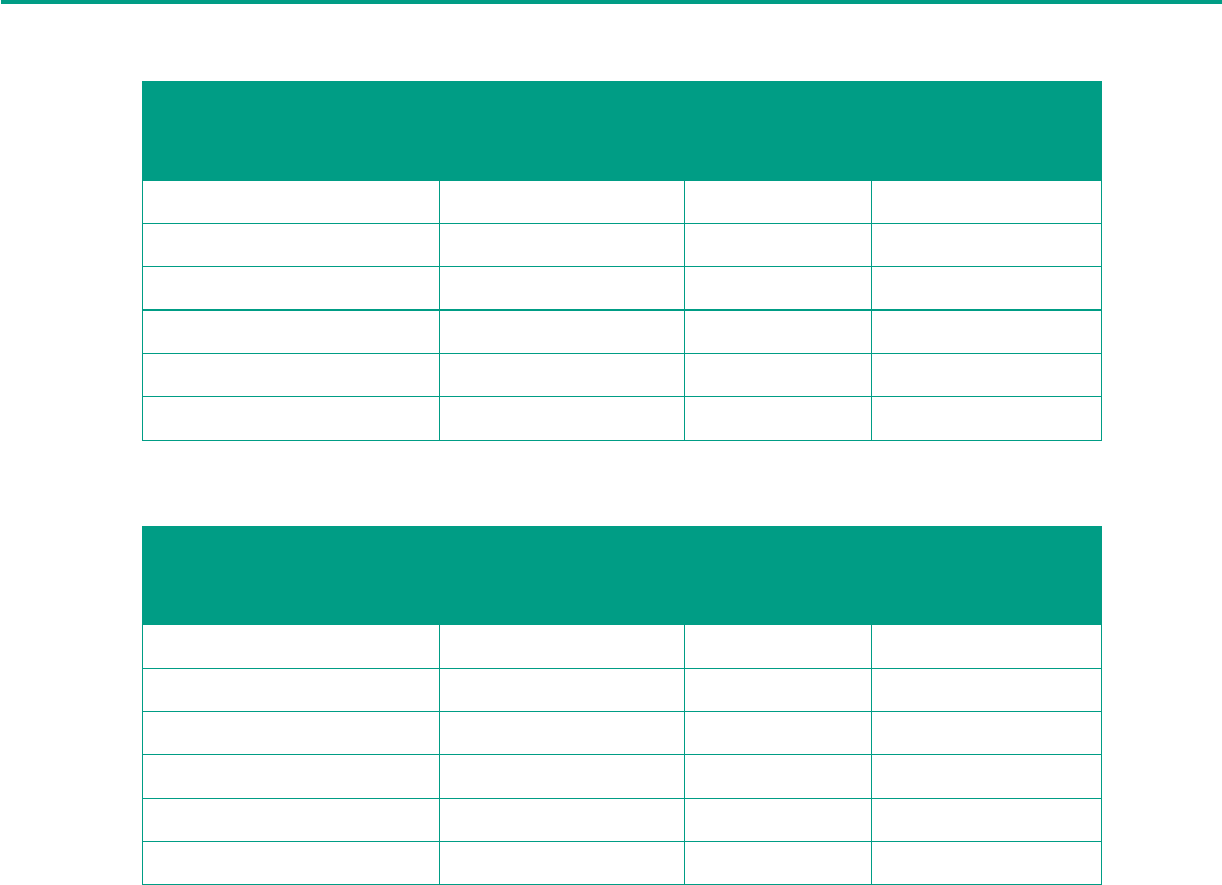

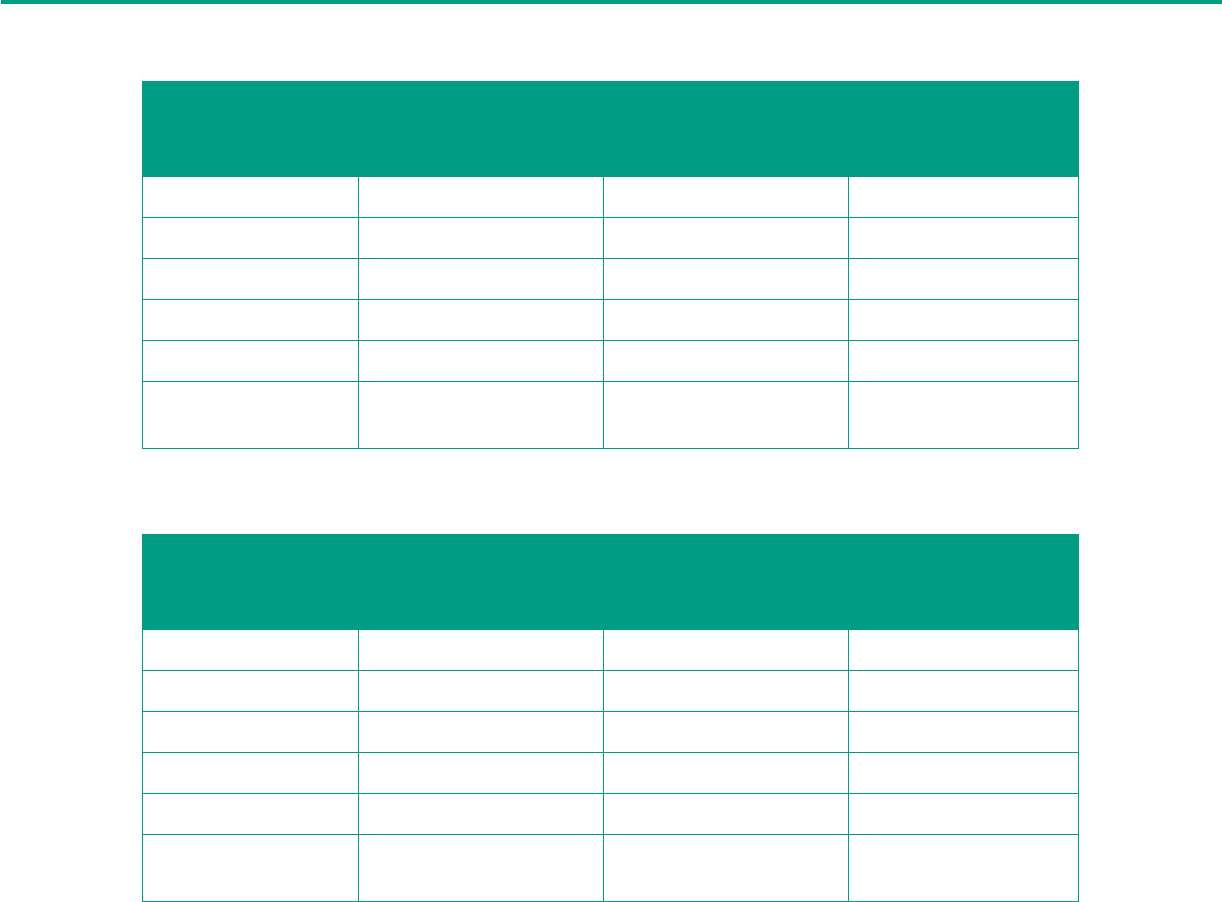

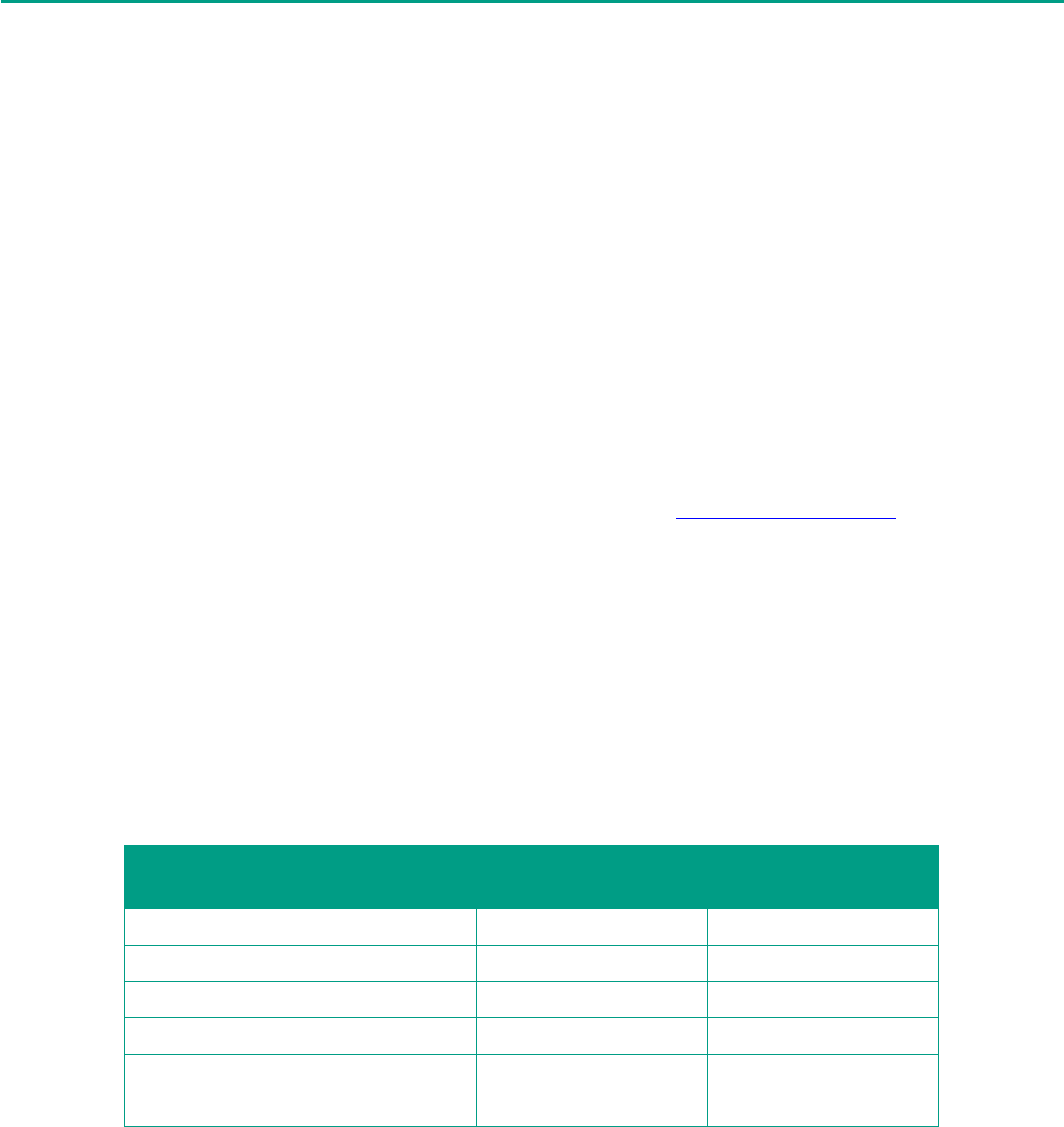

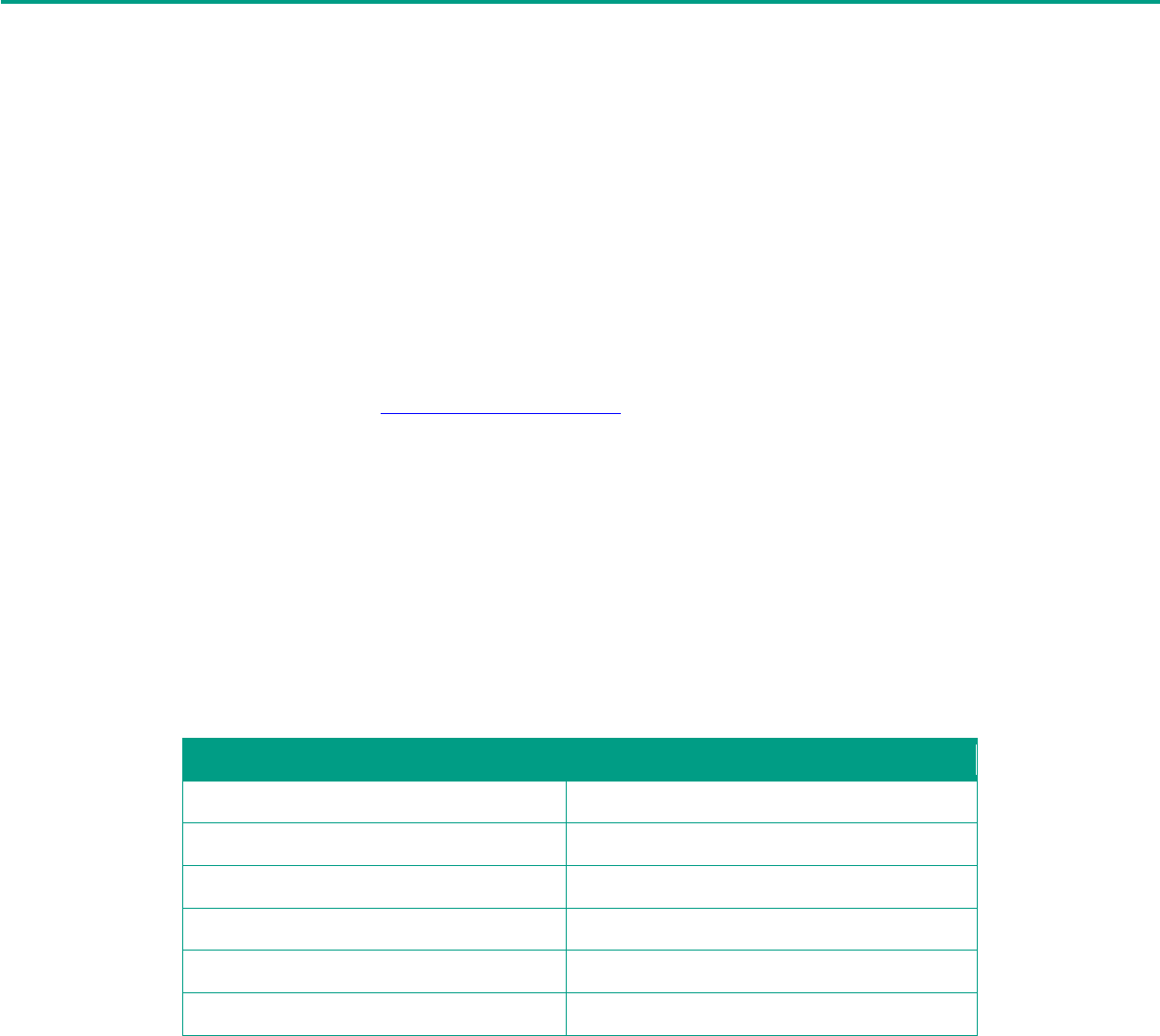

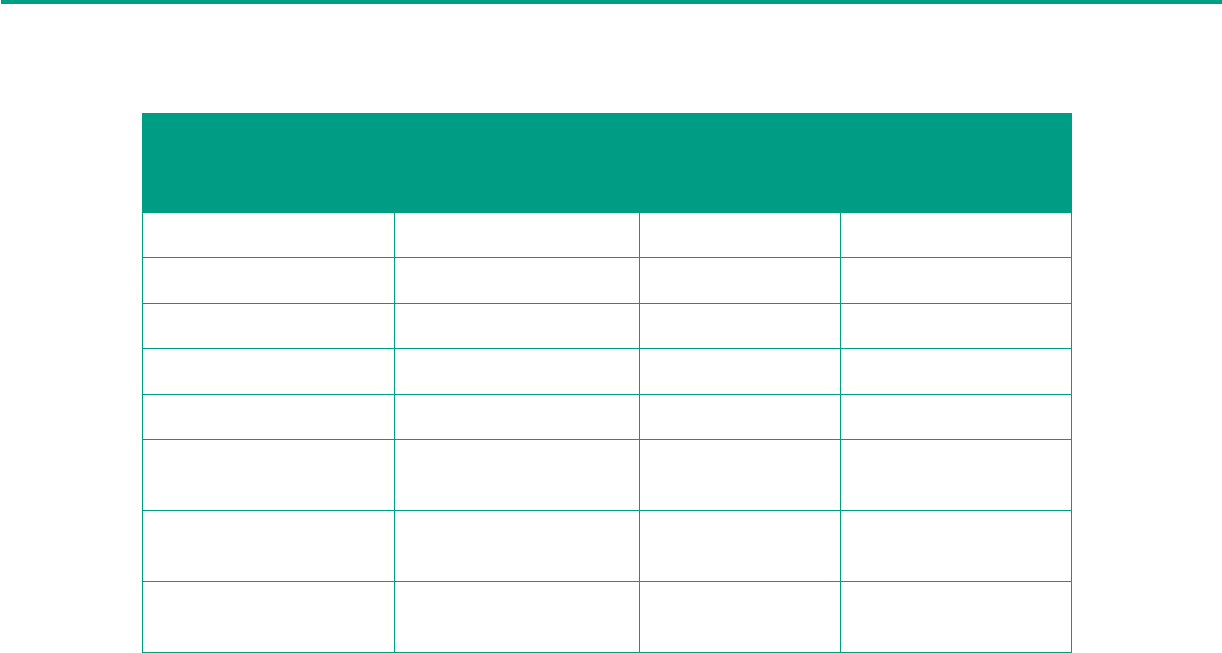

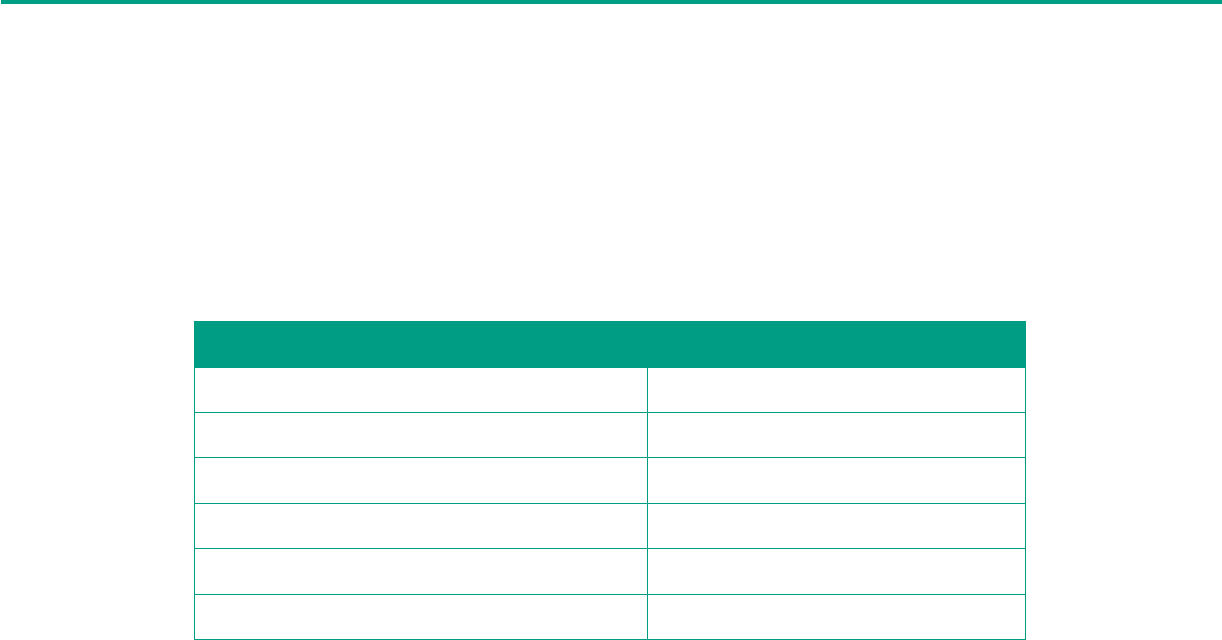

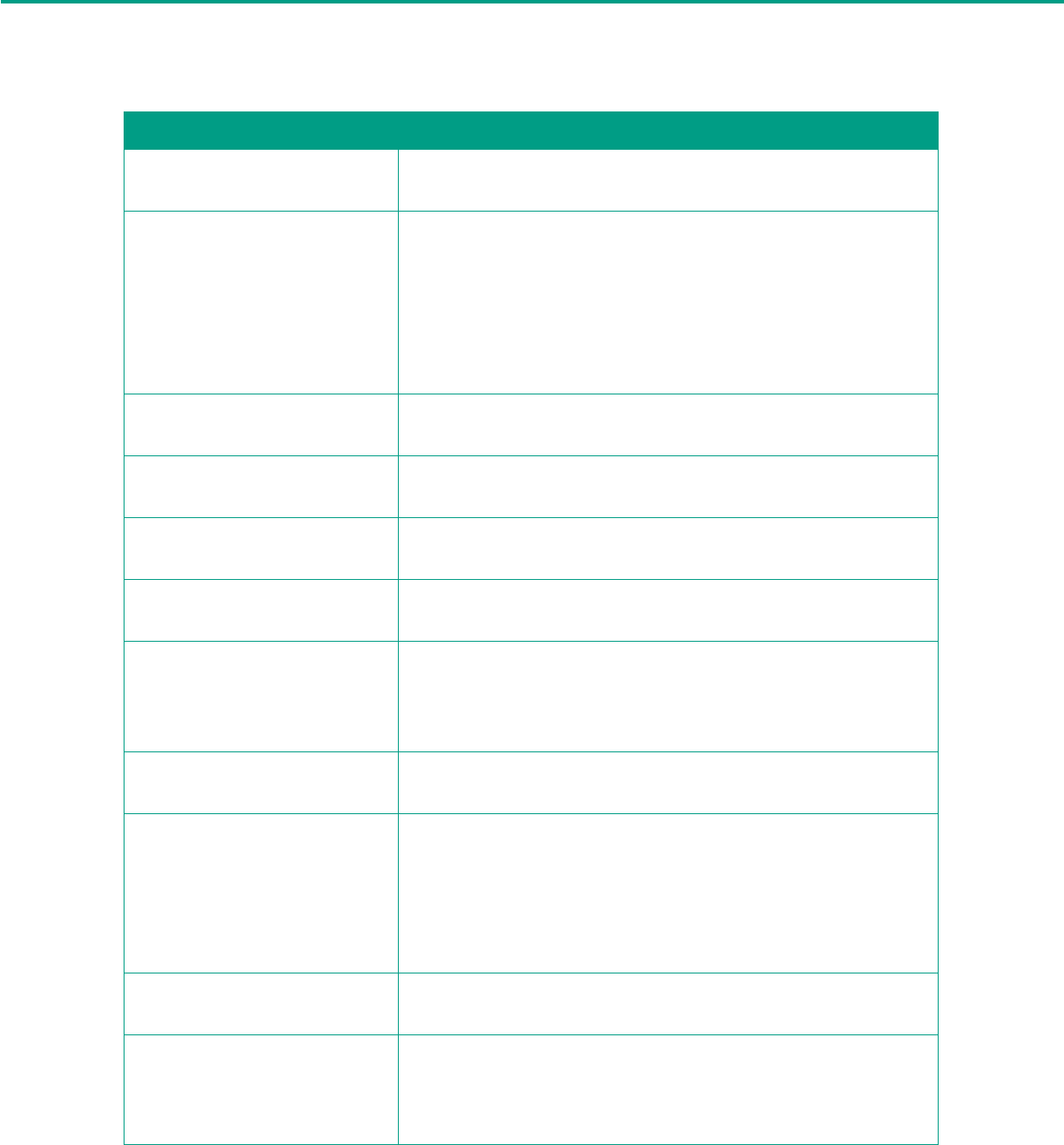

Table 1. Cost and benefit categories.

Project Costs

(Agency Costs)

Project Benefits

(User Benefits)

Externalities

(Non-User Benefits)

• Design and engineering.

• Land acquisition.

• Construction.

• Reconstruction/

Rehabilitation.

• Preservation.

• Routine maintenance.

• Mitigation (e.g., noise

barriers).

• Utility relocation.

• Energy.

• Reduced travel time and

delay.

• Improved travel time

reliability.

• Reduced crash frequency

and/or severity.

• Reduced vehicle

operating cost.

• Reduced air emissions.

• Reduced noise.

• Reduced impacts to

natural habitat and

wetlands.

2.2 WHAT IS SAFETY MANAGEMENT?

Safety management typically comprises three components: planning, implementation, and

evaluation. More specifically, this includes the identification of opportunities for safety

improvement, the implementation of projects to target the identified safety opportunities, and

the evaluation of implemented projects to understand the effectiveness of investments.

Safety management includes planning,

implementation, and evaluation.

There are two general approaches to safety management: 1) selecting and treating sites based

on site-specific crashes (also referred to as the crash-based approach in this Guide), and 2)

selecting and treating sites based on site-specific geometric and operational attributes

associated with increased crash potential (referred to as the systemic approach in this Guide).

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE CHAPTER 2

5

The crash-based and systemic approaches are complementary and support a comprehensive

approach to safety management. To be the most effective, both approaches should focus on

sites with the greatest potential for safety improvement (i.e., preventing future crashes and

reducing fatalities and injuries). For both approaches, it is important to use repeatable and

reliable, data-driven methods such as BCA to inform decisions.

2.2.1 Crash-Based Approach

The crash-based approach involves the identification and evaluation of individual locations with

high potential for safety performance improvement. Transportation agencies use data analysis

techniques to identify locations where a safety improvement opportunity exists and to select

appropriate countermeasures that target site-specific crash-contributing factors.

In the crash-based approach, analysts identify sites based on crash-based performance

measures. The more rigorous crash-based measures use the empirical Bayes (EB) method to

incorporate crash predictions from safety performance functions (SPFs) and site-specific crash

history. Once an agency identifies a list of sites, a multidisciplinary analysis team performs a

detailed review of site-specific crash history and characteristics (e.g., road users, adjacent land

use, geometry, and traffic operations) to identify target crash types and crash-contributing

factors. This provides the foundation for the identification and selection of appropriate

countermeasures to mitigate the specific safety issues (e.g., crash patterns and contributing

factors) at each site.

(2,3,4)

2.2.2 Systemic Approach

The FHWA defines a systemic roadway safety improvement as a proven safety countermeasure

that is widely implemented based on high-risk roadway features that are correlated with

particular severe crash types (23 CFR 924.3).

(5)

FHWA describes systemic projects as having

the following characteristics:

(6)

• Safety opportunities identified through system-wide data, such as rural lane departure

crashes, urban pedestrian crashes, or rural unsignalized intersection crashes. Often,

these opportunities spread across a roadway network.

• Similar projects across a network to address high priority crash types and risk factors.

• Target specific roadway characteristics such as geometry, volume, or location frequently

present in severe crashes.

• Improvements with proven countermeasures on sites identified by the presence of

roadway factors correlated with specific crash types rather than site-specific crashes.

• Generally low-cost improvements (e.g., enhanced signing or striping, rumble strips, or

signal heads upgrades). Higher-cost improvements are candidates for the systemic

approach, but the improvement should be highly effective to justify the increased cost.

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE CHAPTER 2

6

The following section describes the roadway safety management process that is generally

applicable to both the crash-based and systemic approach.

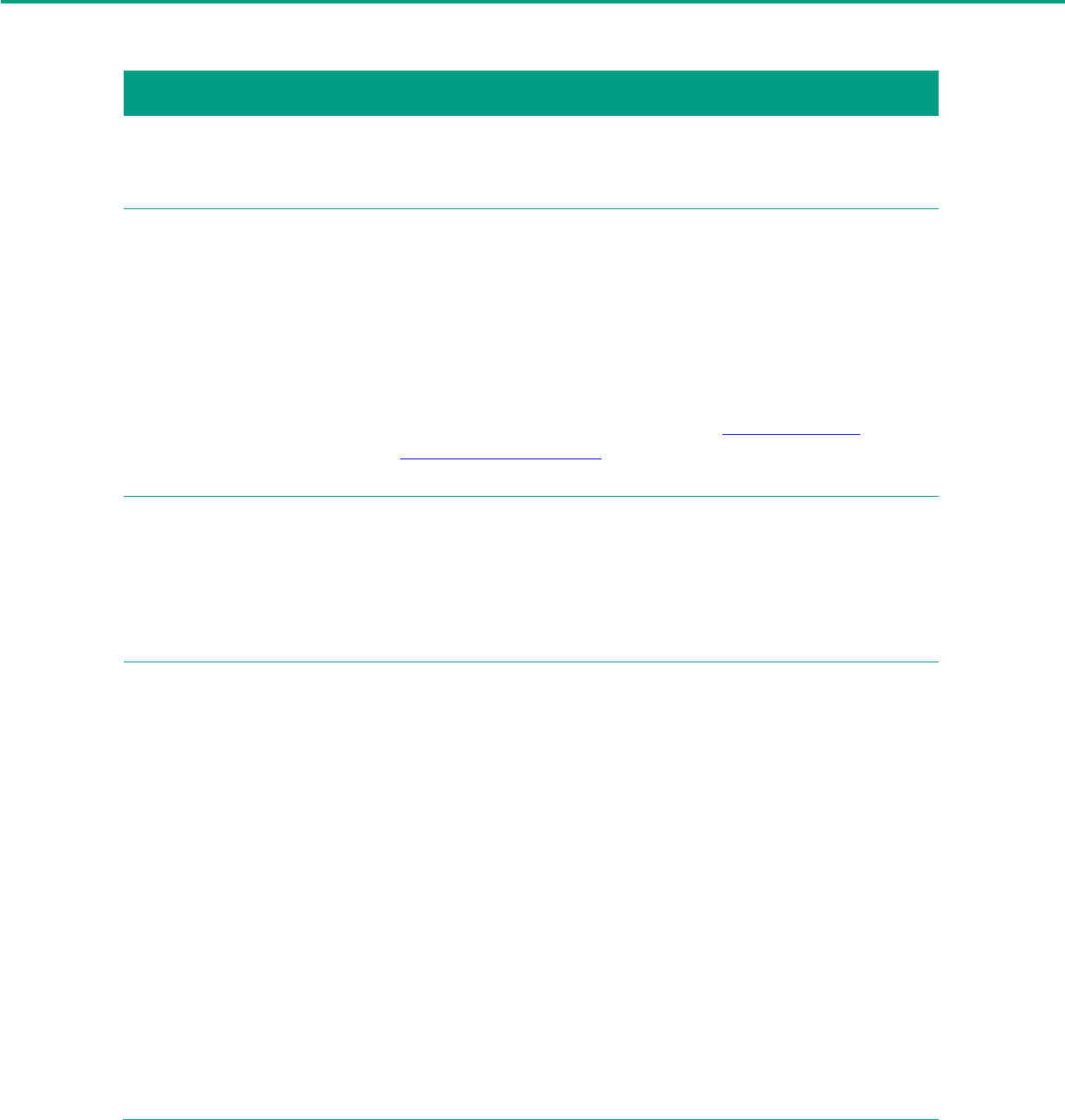

2.2.3 Roadway Safety Management Process

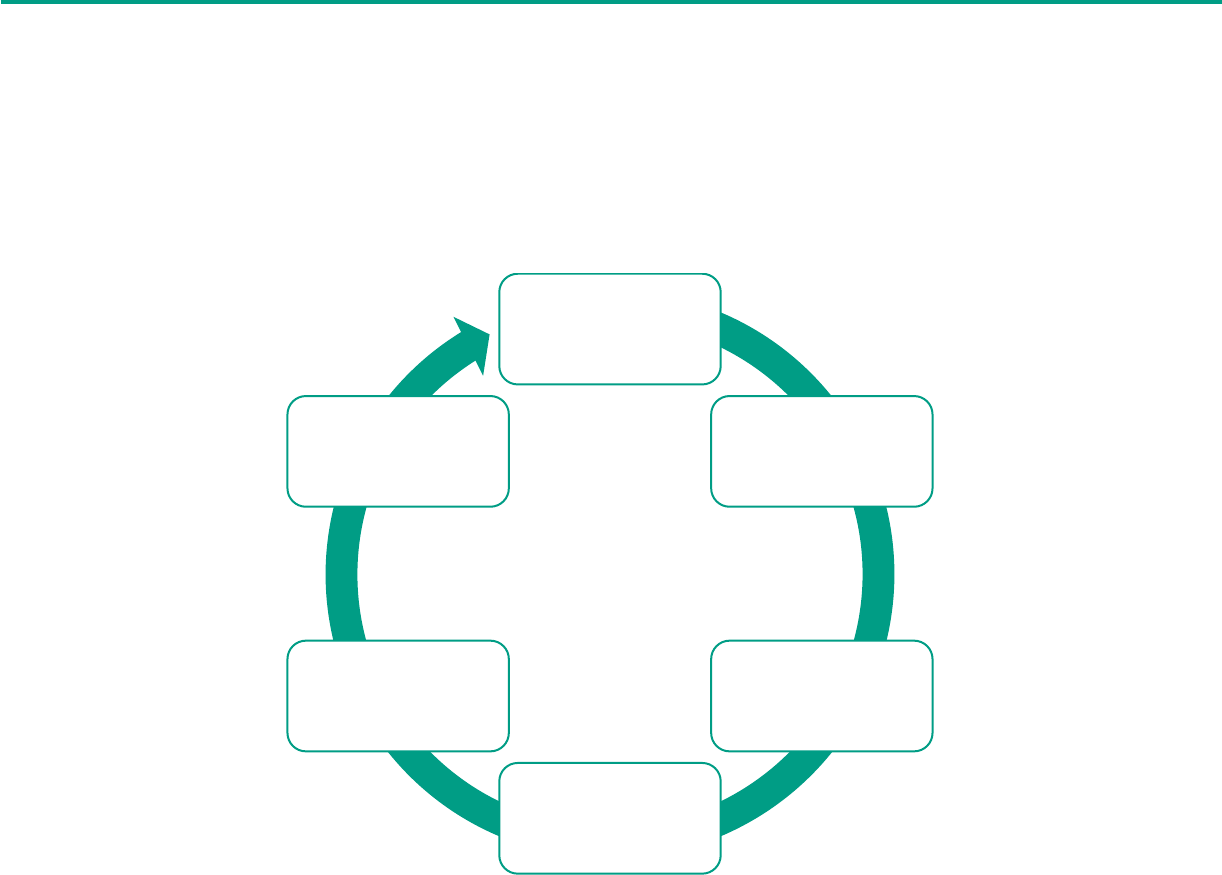

The roadway safety management process is a six-step process as shown in Figure 1 and outlined in

the Highway Safety Manual.

(7)

Figure 1. Chart. Roadway safety management process.

The objectives of this process are as follows.

(4)

1. Network Screening: Identify locations that could benefit from treatments to improve

safety performance (i.e., reduce crash frequency and severity).

2. Diagnosis: Understand collision patterns and crash contributing factors.

3. Countermeasure Selection: Identify, assess, and select appropriate countermeasures to

target crash contributing factors and reduce crash frequency and severity at locations with

potential for improvement.

4. Economic Appraisal: Estimate the economic cost and benefit associated with a particular

countermeasure or set of countermeasures. This Guide focuses on the use of BCA in

economic appraisal to consider the relative costs and benefits among alternatives.

Step 1

Network Screening

Step 2

Diagnosis

Step 3

Countermeasure

Selection

Step 4

Economic Appraisal

Step 5

Project Prioritzation

Step 6

Safety Effectiveness

Evaluation

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE CHAPTER 2

7

5. Project Prioritization: Develop a prioritized list of projects to improve the safety

performance (i.e., reduce crash frequency and severity) of the road network,

considering available resources. Project prioritization involves policy-level decisions such

as overall agency goals and may include multiple (and sometimes competing) factors

such as safety, operational efficiency, environmental impacts, and equity. This Guide

does not cover project prioritization.

6. Safety Effectiveness Evaluation: Evaluate how a project (or group of projects) has

affected the safety performance of the treated location(s) and the system. The evidence-

based safety effectiveness estimates developed in step 6 (safety effectiveness evaluation)

support future decisions.

The roadway safety management process is an integral part of the project development

process. While the roadway safety management process focuses on safety performance, the

results of countermeasure selection, economic appraisal, and project prioritization feed into the

project development process (i.e., system planning, project planning, project design and

construction, and system operations and maintenance).

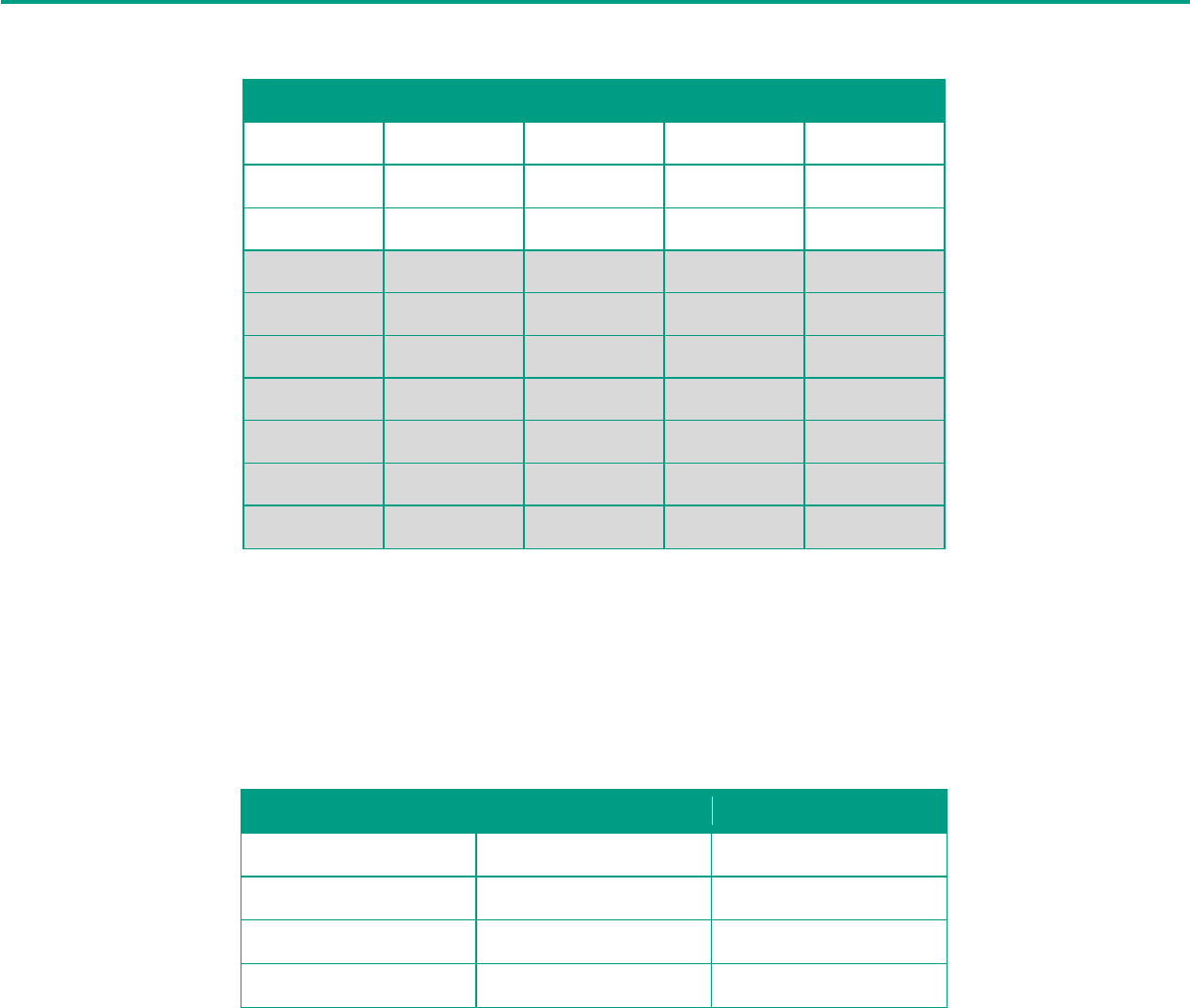

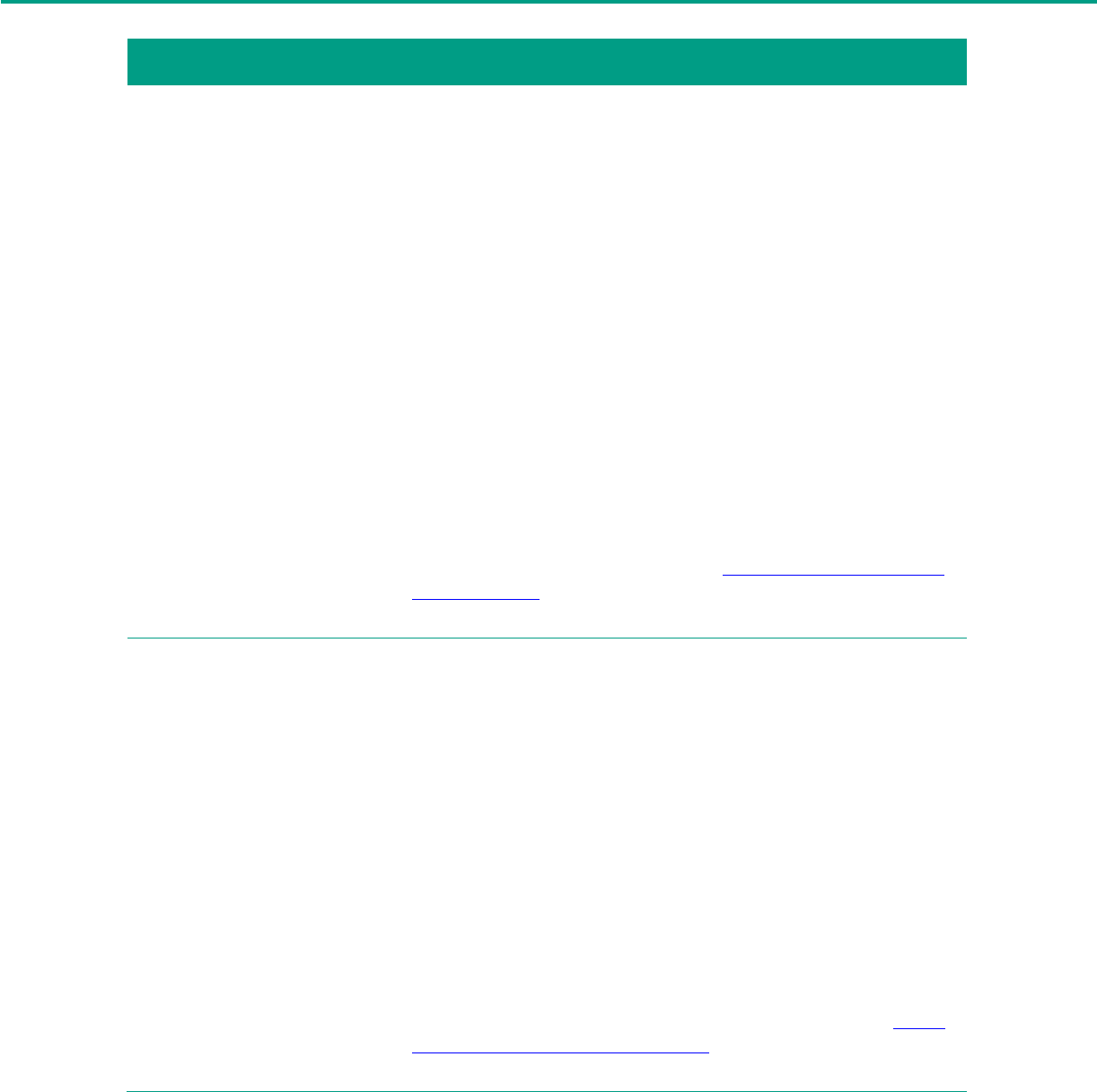

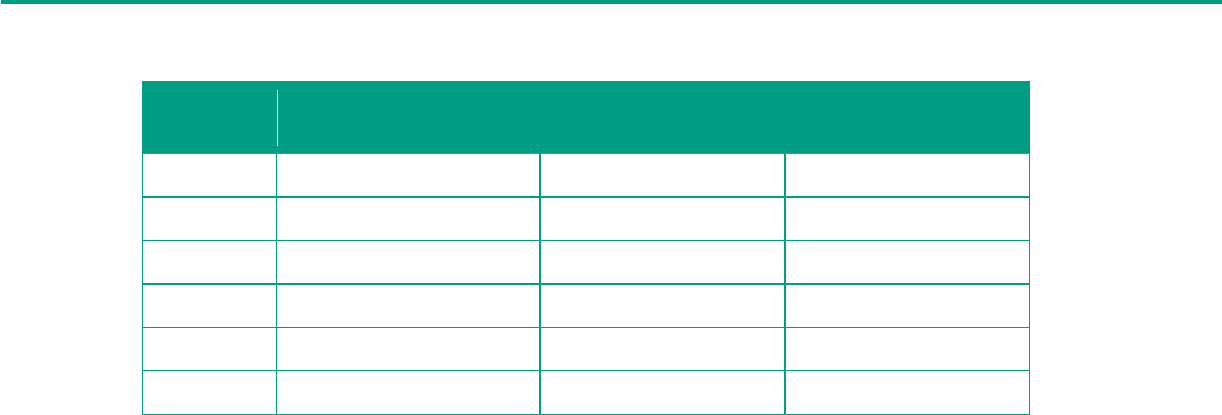

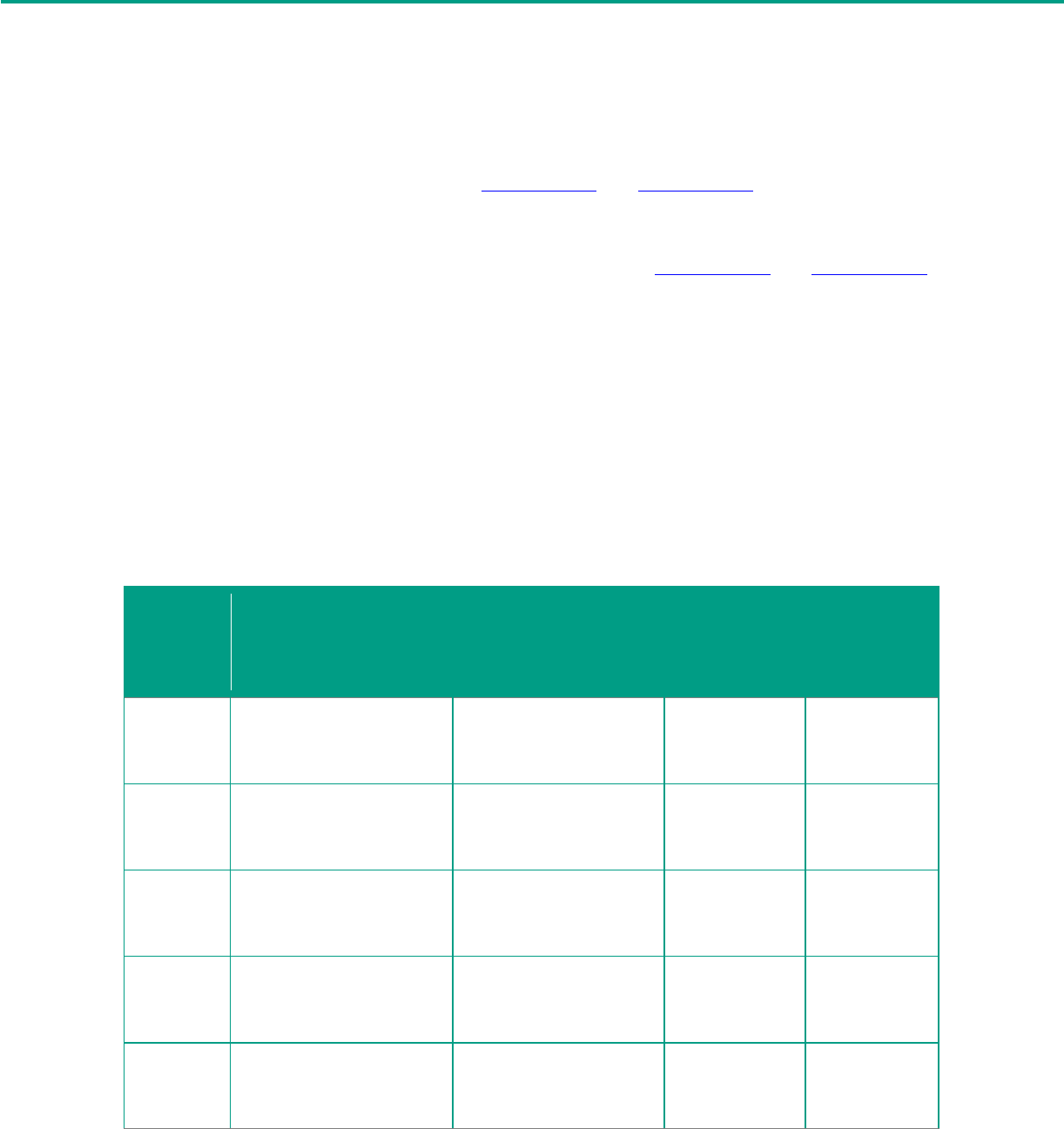

2.3 ECONOMIC MEASURES FOR BCA

Agencies can use various measures, indices, and factors to compare and select among project

alternatives. Table 2 lists common economic measures for BCA. Three of these measures

(indicated in bold) directly compare monetary benefits and costs, which is needed to accurately

assess the cost-effectiveness of project alternatives. Following the table is a detailed description

of each measure.

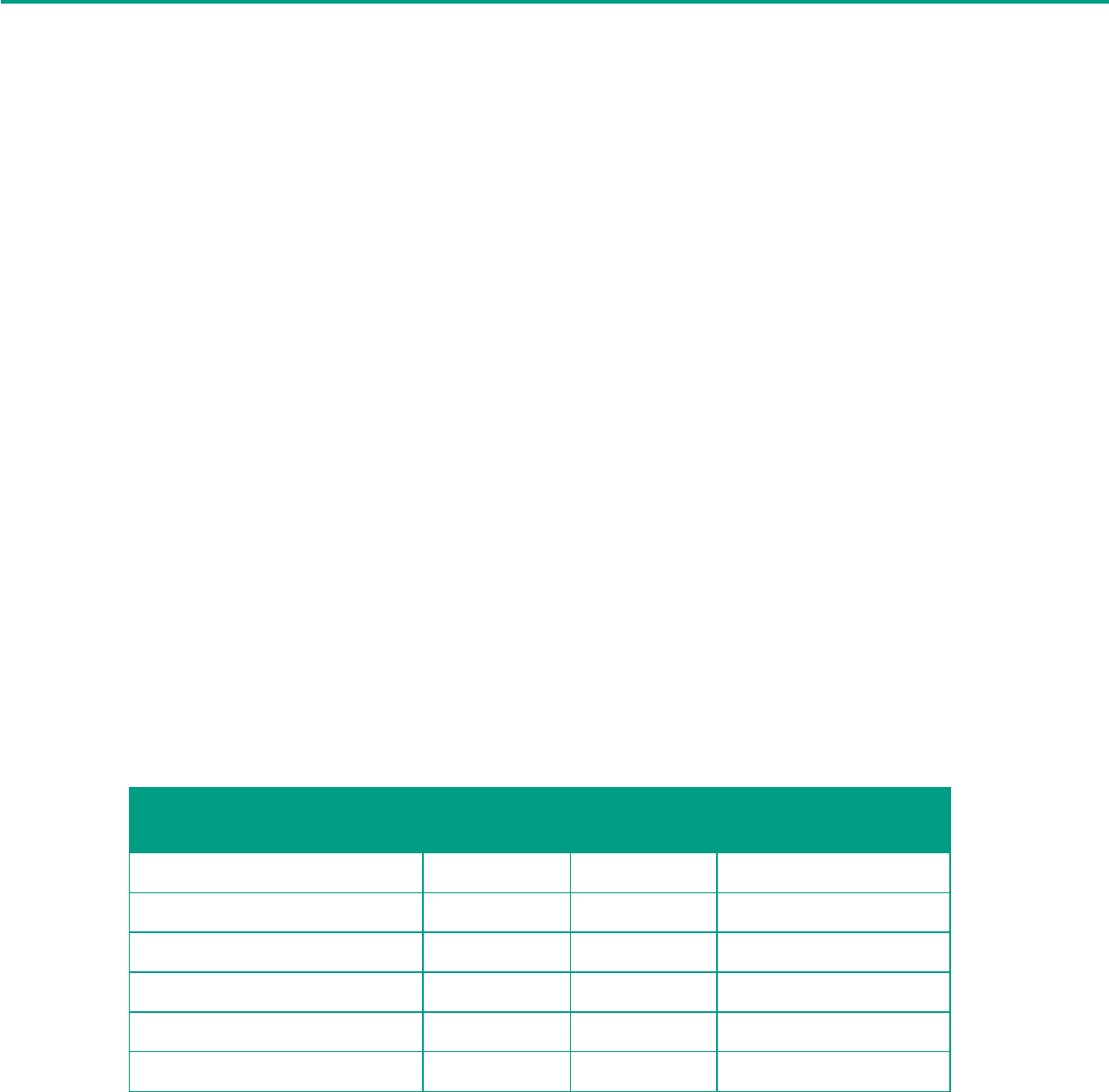

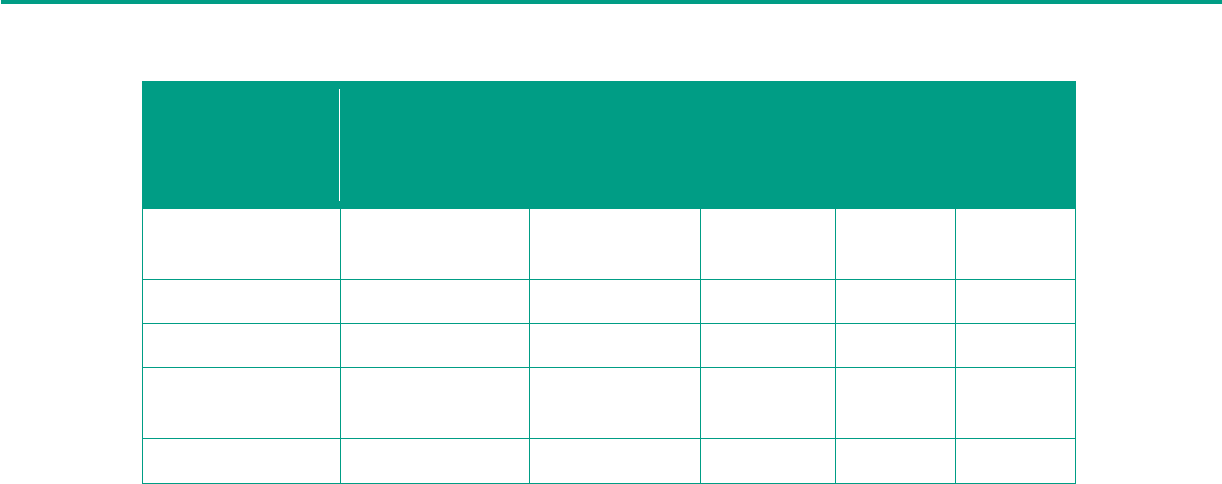

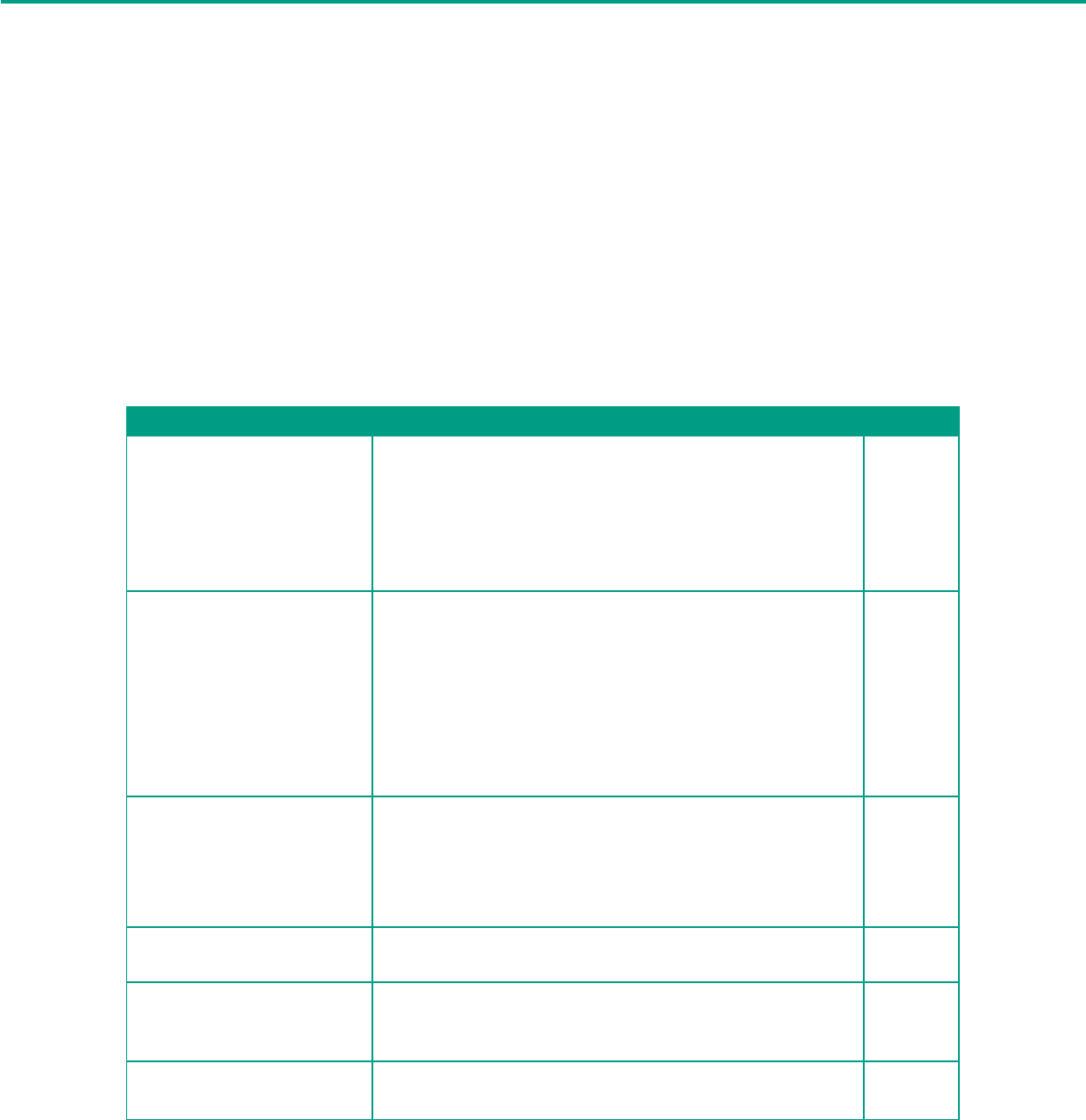

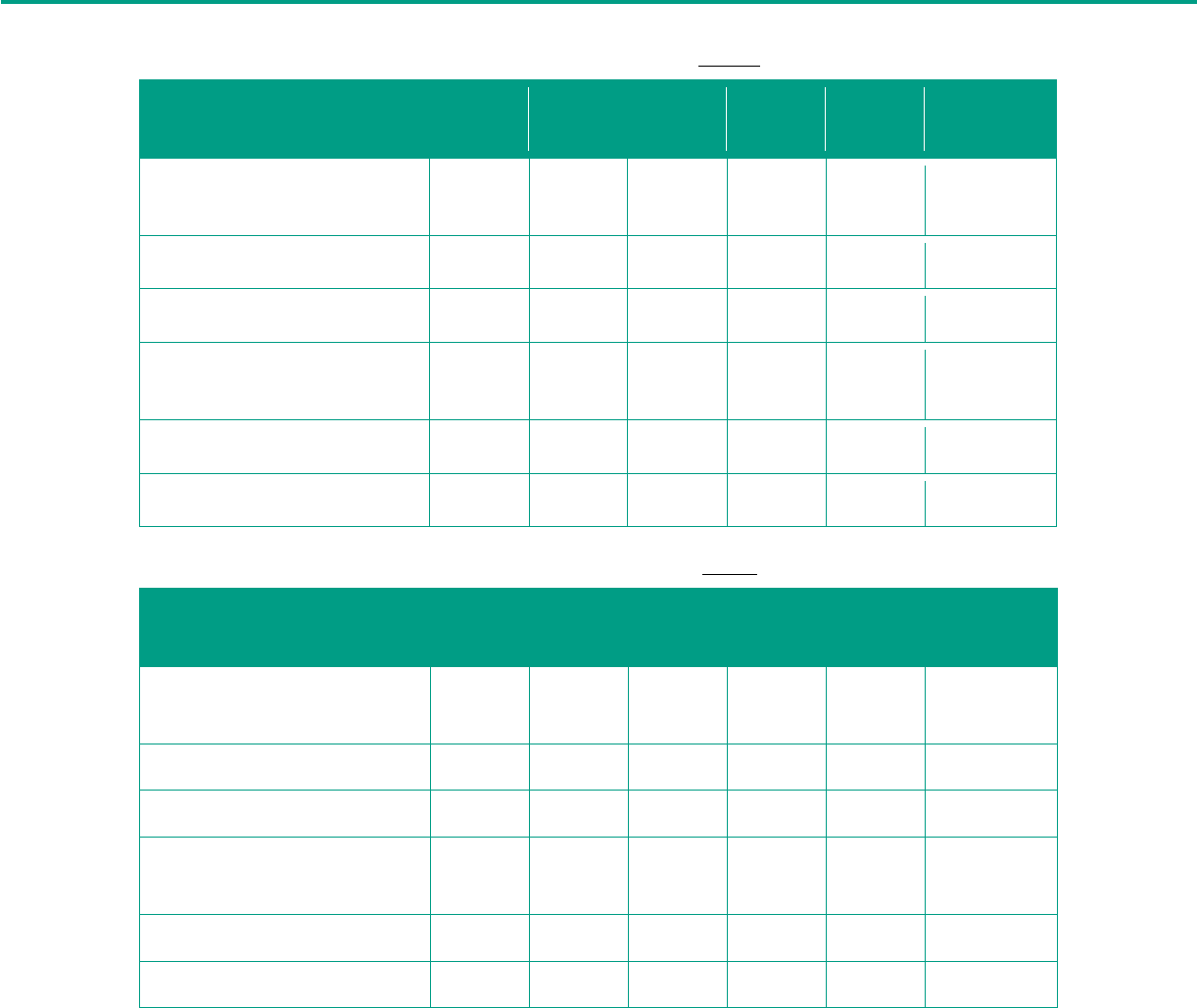

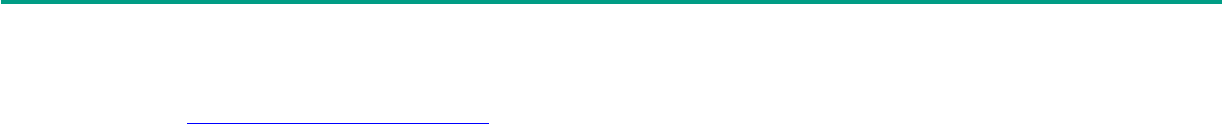

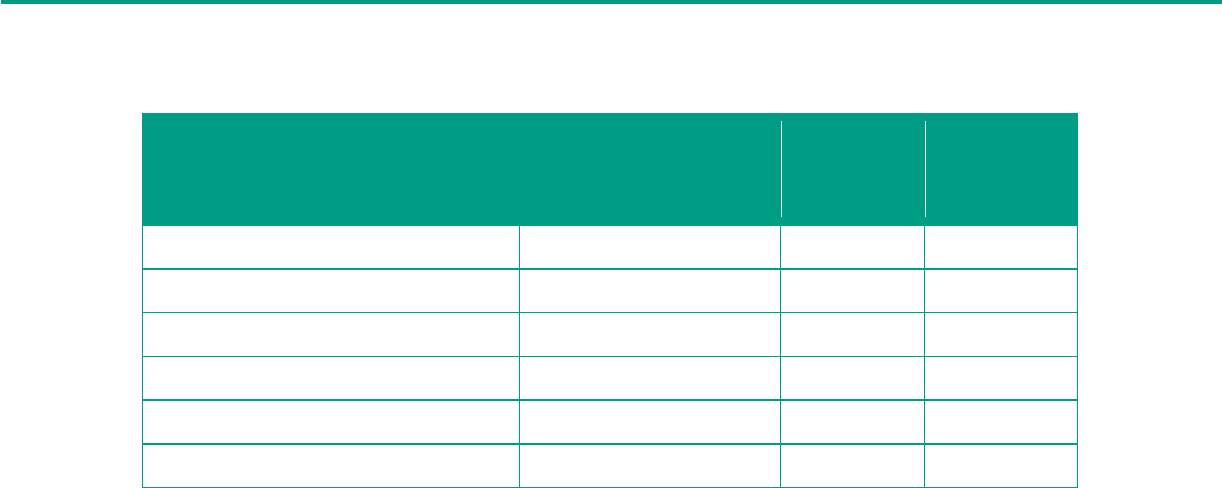

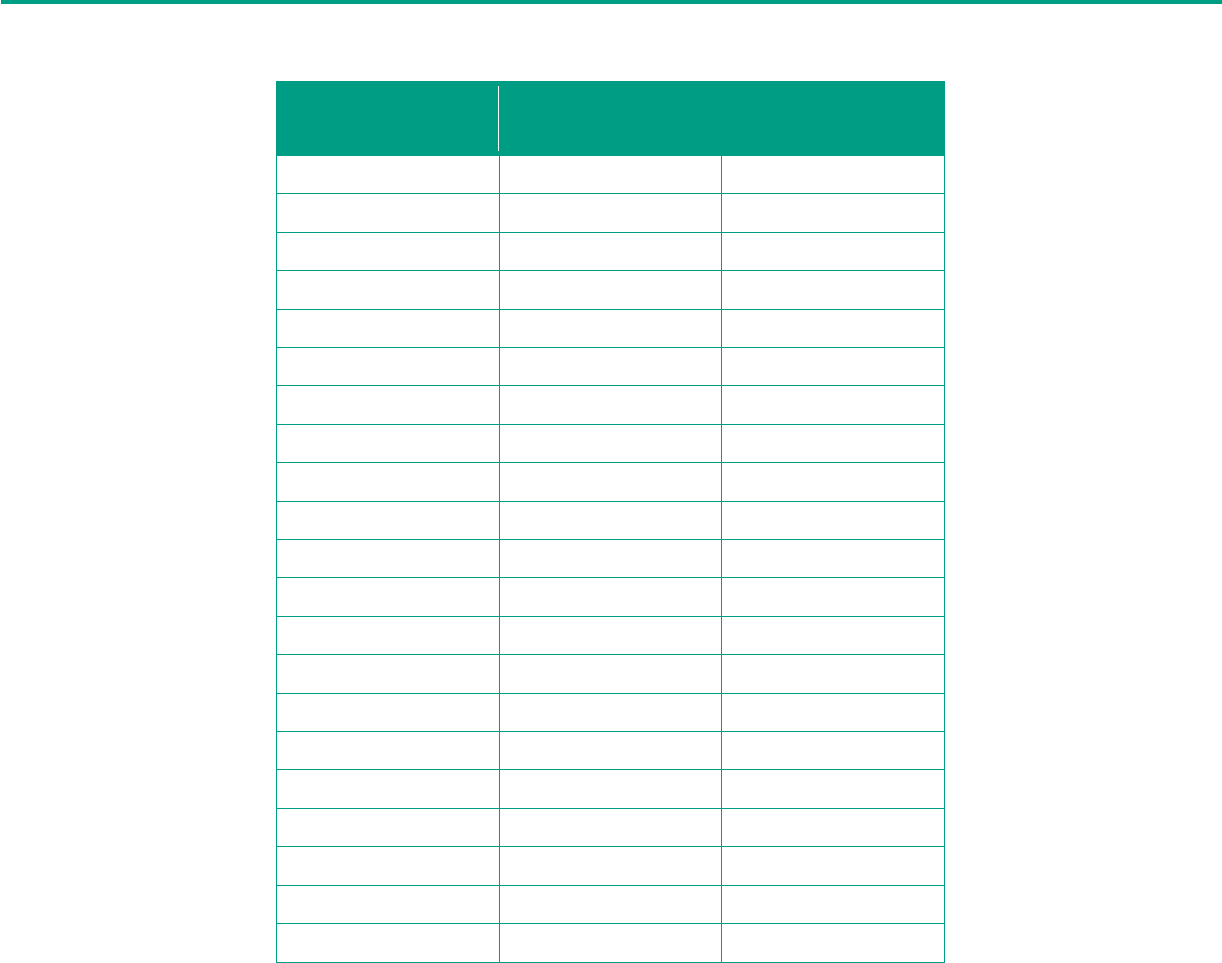

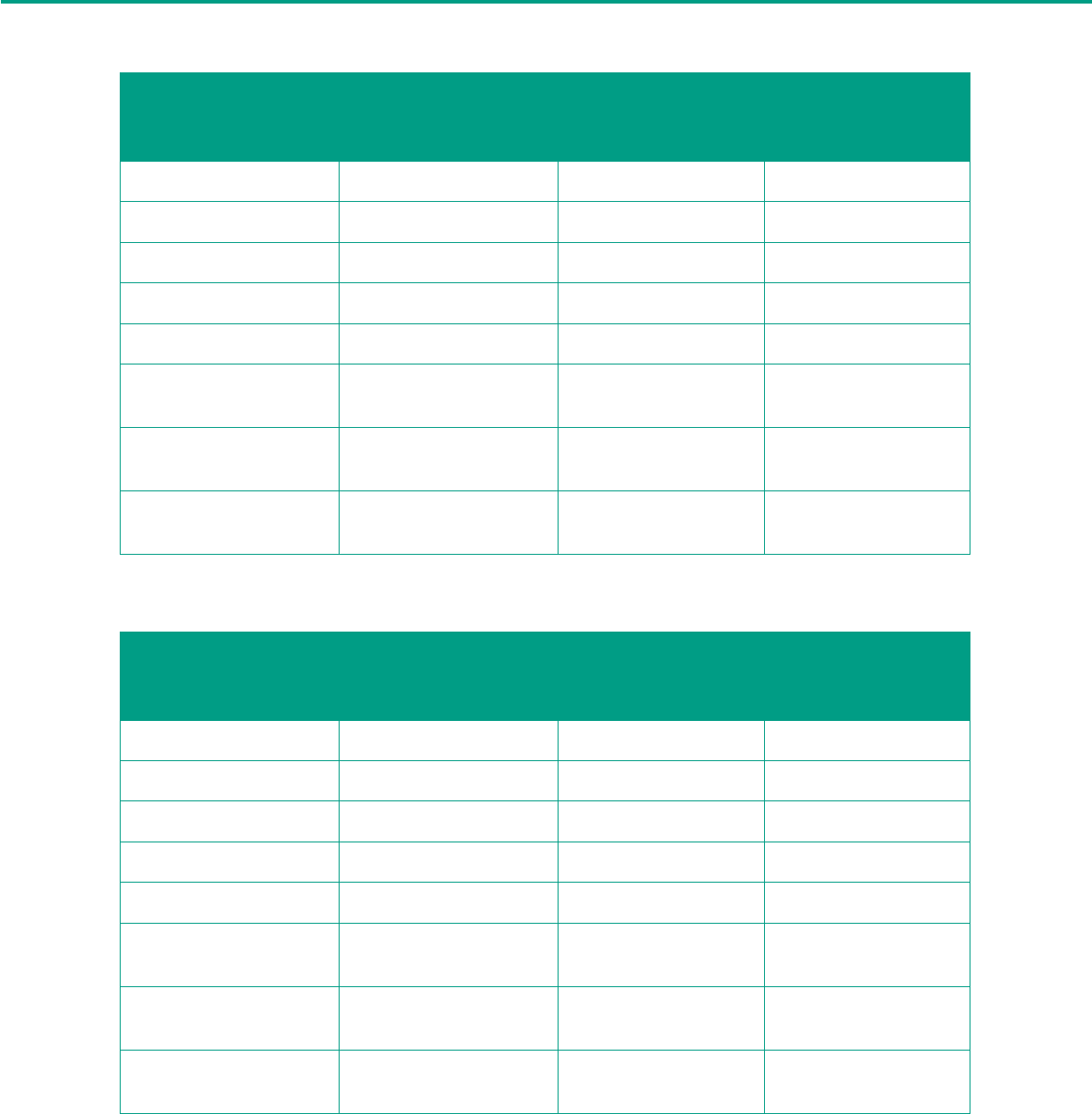

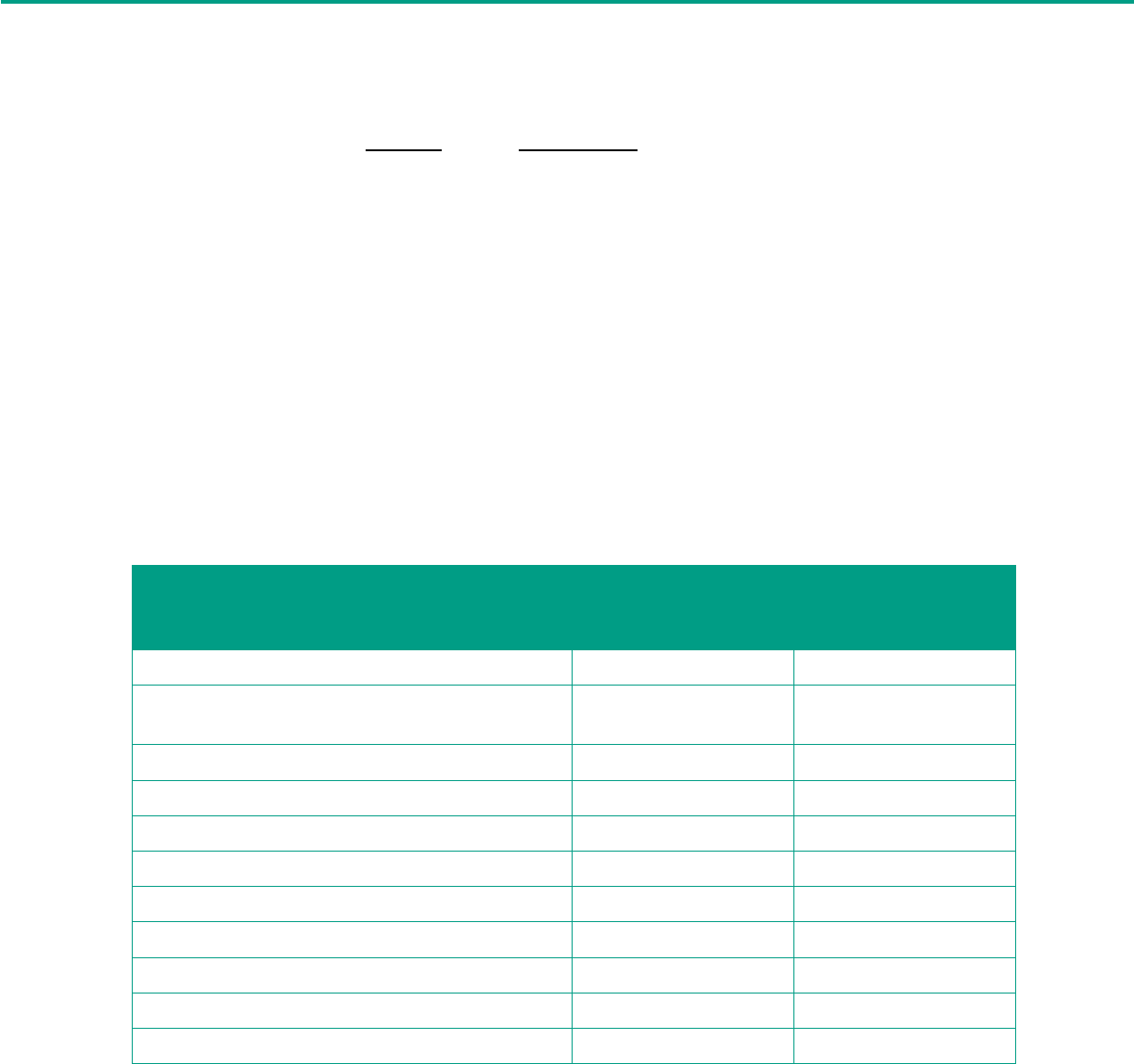

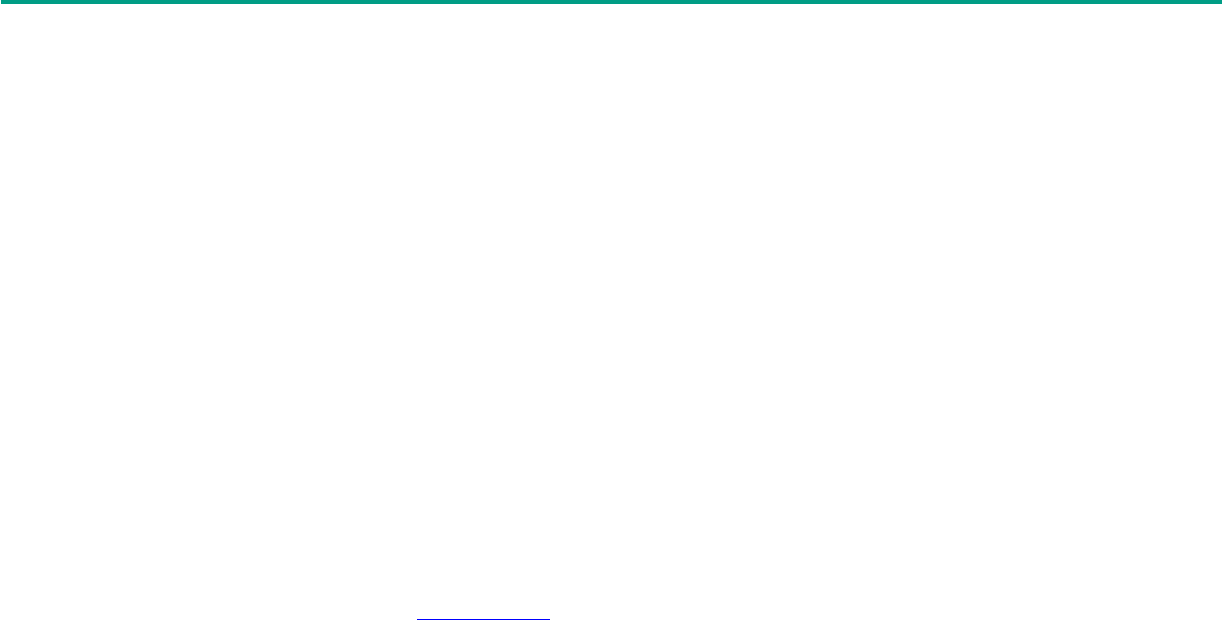

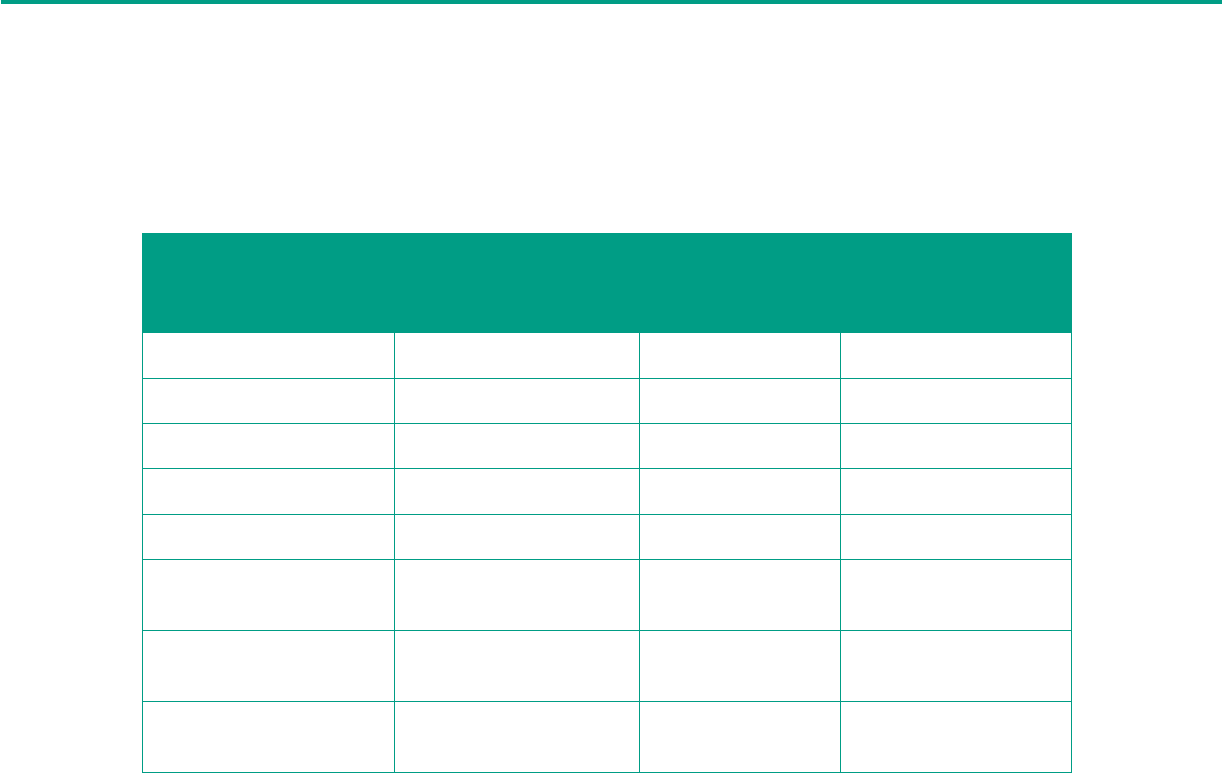

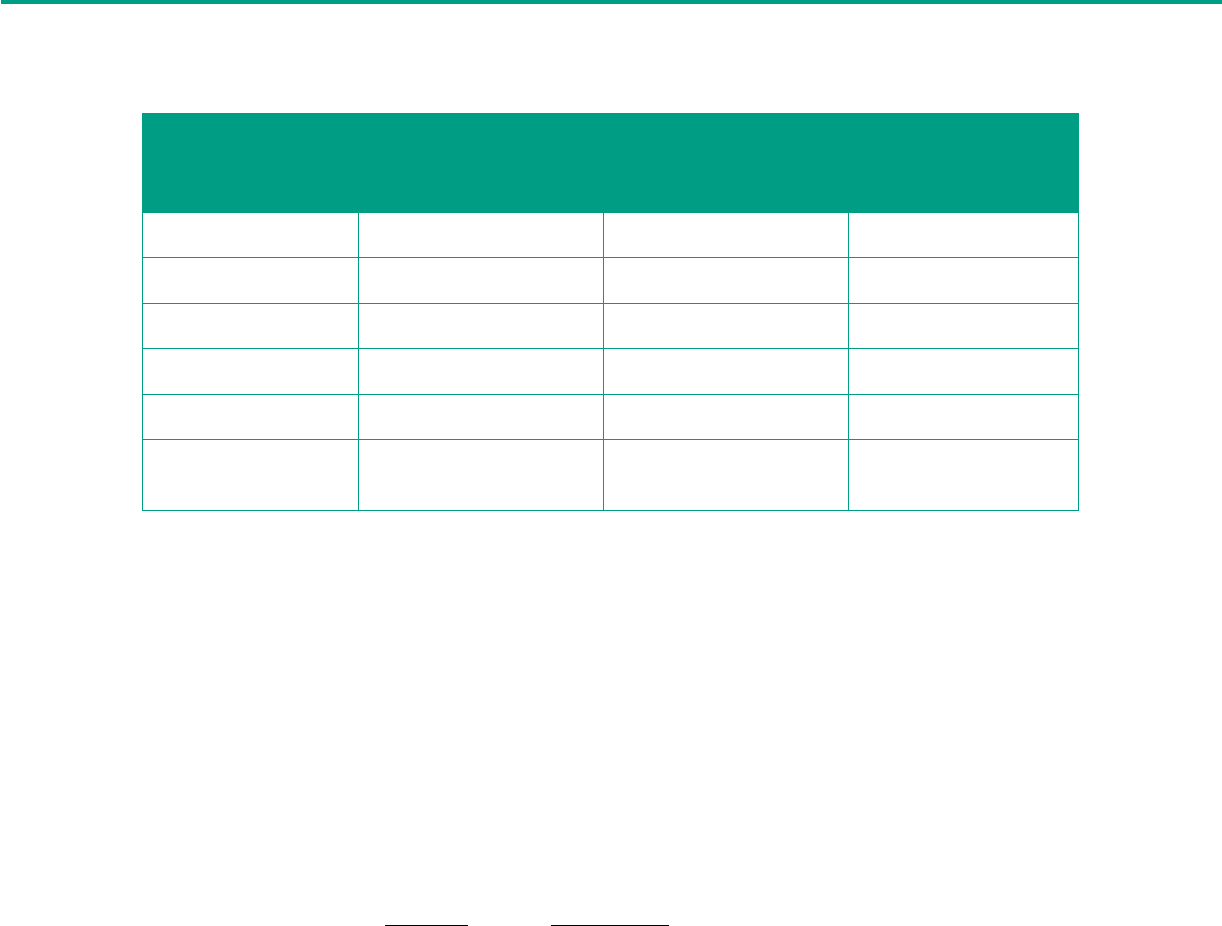

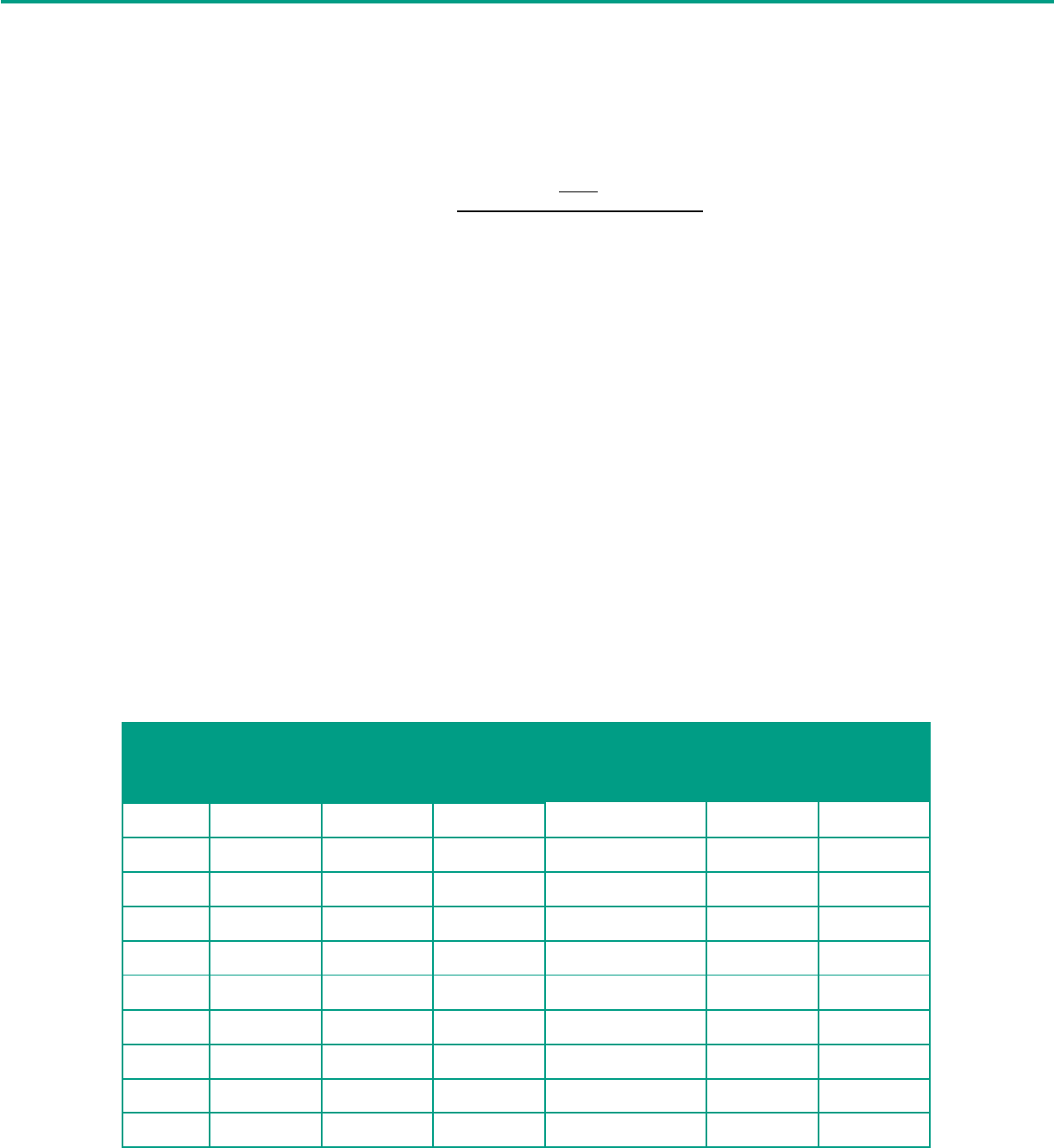

Table 2. Comparison of economic appraisal measures.

Economic Measure

Considers

Costs

Considers

Benefits

Considers Monetary

Costs and Benefits

Present value cost (PVC)

Yes

No

No

Present value benefit (PVB)

No

Yes

No

Cost-effectiveness index (CEI)

Yes

Yes

No

Benefit-cost ratio (BCR)

Yes

Yes

Yes

Net present value (NPV)

Yes

Yes

Yes

Payback period

Yes

Yes

Yes

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE CHAPTER 2

8

2.3.1 Present Value Costs (PVC)

The PVC is the present value of all costs incurred from implementing a project over the service

life (e.g., engineering, right-of-way, construction, maintenance, change in road user costs). A

positive value of PVC represents funds expended; a negative value represents a savings or influx

of funds.

2.3.2 Present Value Benefits (PVB)

The PVB is the monetized present value of the expected change in crashes from implementing a

project (i.e., expected change in crashes multiplied by average crash costs). Benefits may include

all crashes, although some agencies only consider the changes to fatal and serious injury crashes

(or other crash type and/or severity combinations). A positive PVB represents a crash

reduction; a negative value represents an increase in crashes.

2.3.3 Cost-Effectiveness Index (CEI)

The CEI is the average cost of a project to reduce one crash. The CEI is calculated by dividing

the PVC by the expected number of crashes reduced over the service life of the project as

shown in Figure 2. In general, a low CEI is desirable. The CEI is typically based on total crashes,

but can be expressed in terms of a specific crash type or severity level (e.g., cost to reduce one

fatal and serious injury crash). The CEI does not account for the monetary benefits. As such, it

is not an appropriate measure to justify projects economically. It can, however, serve as a

measure when it is difficult to monetize benefits (e.g., when an agency has not adopted crash

cost values).

Figure 2. Equation. Cost-effectiveness index.

2.3.4 Benefit-Cost Ratio (BCR)

The BCR is the ratio of present value benefits (including negative benefits) to present value

costs (initial and continuing costs over the project lifecycle), as shown in Figure 3. In this

context, the BCR is the same as the rate of return and return on investment. A BCR greater

than 1.0 indicates that benefits exceed costs, and the project is economically justified. In

general, a higher BCR is desirable. The BCR is most appropriate for prioritizing alternatives

when funding restrictions apply (e.g., prioritizing countermeasures or locations within a project

with a fixed budget).

Figure 3. Equation. Benefit-cost ratio.

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE CHAPTER 2

9

2.3.5 Net Present Value (NPV)

The NPV is the difference between present value benefits and present value costs, as shown in

Figure 4. NPV is also sometimes called net benefits or net present worth. If the NPV is greater

than 0.0, then the benefits exceed the costs, and the project is economically justified. In general,

a higher NPV is desirable. An agency can use NPV to determine the alternative with the highest

benefits for a given project.

Figure 4. Equation. Net present value.

2.3.6 Payback Period

The payback period is the length of time, in years, to reach the breakeven point on the

investment, measured from the end of construction to when the PVB equals the PVC.

2.3.7 Summary of Economic Measures

The BCR and NPV are generally the most appropriate measures to assess and prioritize project

alternatives in highway safety BCA. The BCR is insensitive to the magnitude of net benefits;

therefore, it may prioritize projects with relatively lower costs and benefits over those with

higher net benefits. The use of NPV can help to identify projects with the higher net benefits.

The payback period does not consider the full extent of benefits (i.e., only up to the value of

costs).

The United States Department of Transportation (USDOT) recommends the use of BCR or

NPV for most economic evaluations.

(8)

Analysts may consider a combination of measures (e.g.,

BCR and NPV) or other available BCA measures (e.g., equivalent uniform annual value

approach or internal rate of return) depending on the policy or preference of the agency. Refer

to resources such as the Transportation Systems Management and Operations Benefit-Cost

Analysis Compendium for definitions of the equivalent uniform annual value approach and

internal rate of return.

(9)

Chapter 7 illustrates the use of the BCR and NPV to assess

alternatives through practical applications of BCA in various scenarios.

The BCR and NPV are often the most appropriate

economic measures to assess alternatives.

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE CHAPTER 2

10

2.4 USE OF HIGHWAY SAFETY BCA IN SAFETY MANAGEMENT AND

PROJECT DEVELOPMENT

The safety management process and project development process often include the comparison

of multiple project alternatives. This may include alternative designs for a specific location or

alternative locations as part of a systemic improvement project. Highway safety BCA helps to

compare the cost-effectiveness of alternative designs, and enables decision-makers, planners,

highway designers, and traffic engineers to consider safety-motivated projects in conjunction

with resurfacing, rehabilitation, reconstruction, and expansion projects.

Decision-makers use BCA to compare the cost-

effectiveness of alternatives or projects.

Highway safety BCA can indicate which alternative provides the most efficient or effective

safety benefit to highway users. The most efficient (i.e., most cost-effective) alternative

provides the largest benefit per dollar spent (i.e., highest BCR). The most effective alternative

provides the largest net benefit to the public (i.e., highest NPV).

In general, this Guide focuses on the use of BCA in economic appraisal to quantify, assess, and

compare the costs and benefits of alternatives for a specific location. Specifically, this Guide will

help users to quantify project benefits and costs to determine the most efficient and effective

alternative. While BCA is essential to conducting economic appraisal, the results are also useful

in project prioritization (i.e., the comparison of alternative projects as part of a program). This

Guide covers project prioritization in the context of prioritizing alternatives within a project.

This includes projects with multiple alternatives where some of the alternatives are subsets of a

more comprehensive alternative. Further, this applies to the selection of a subset of multiple

potential locations in a systemic improvement project. The following sections compare the use

of BCR and NPV measures in prioritizing alternatives within a project to achieve the most

efficient or effective project.

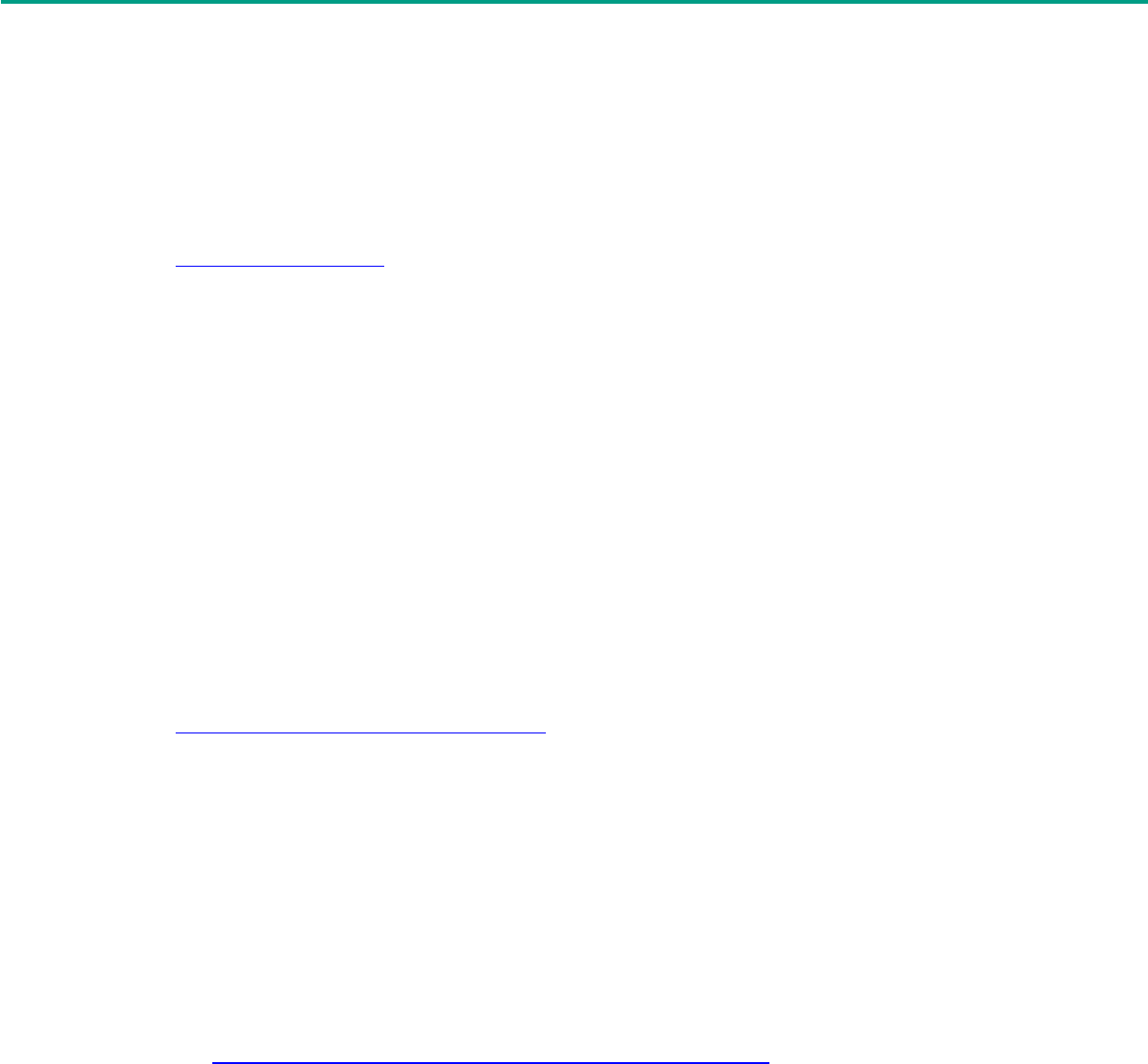

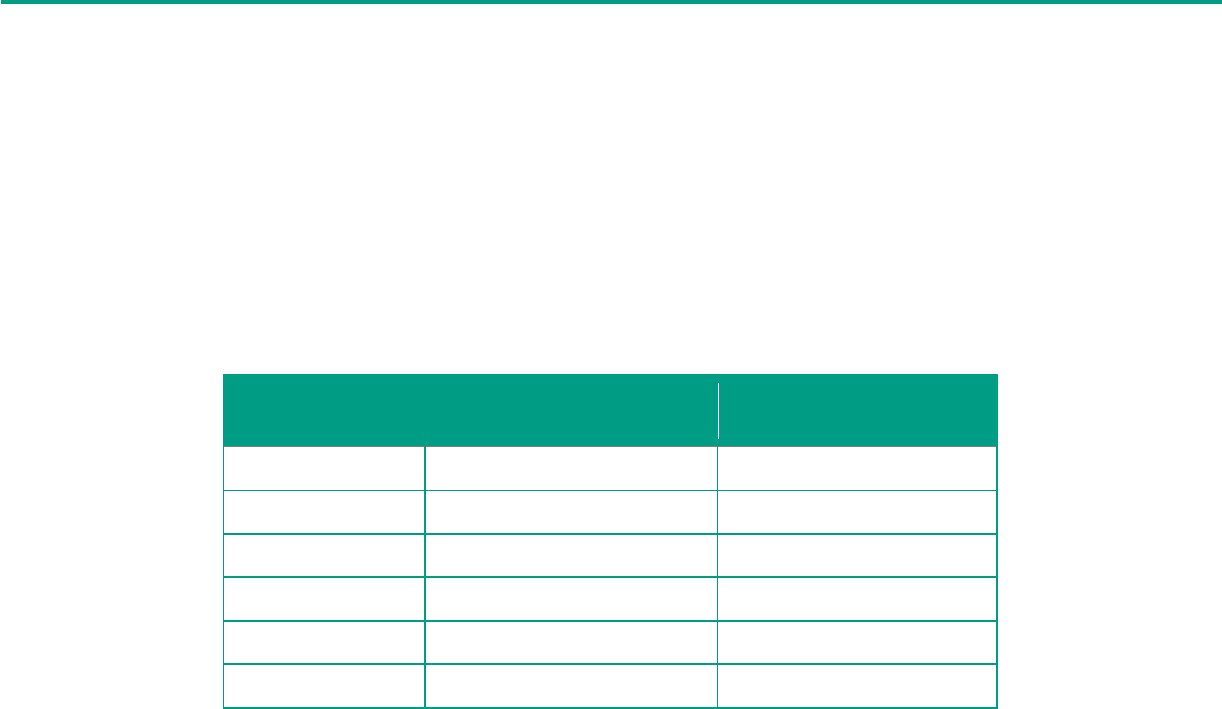

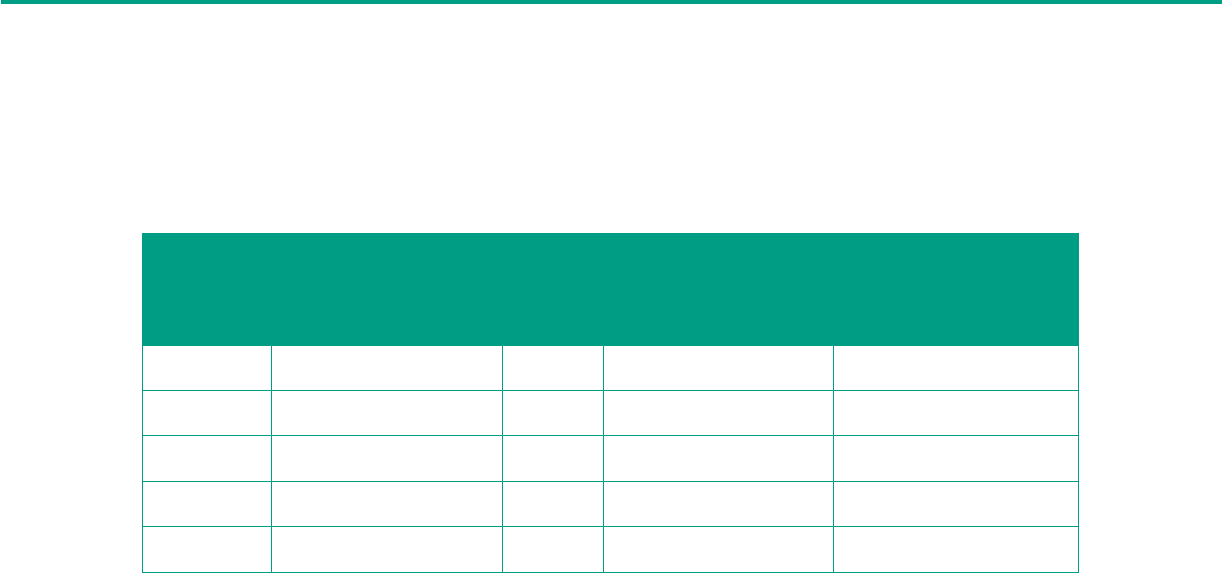

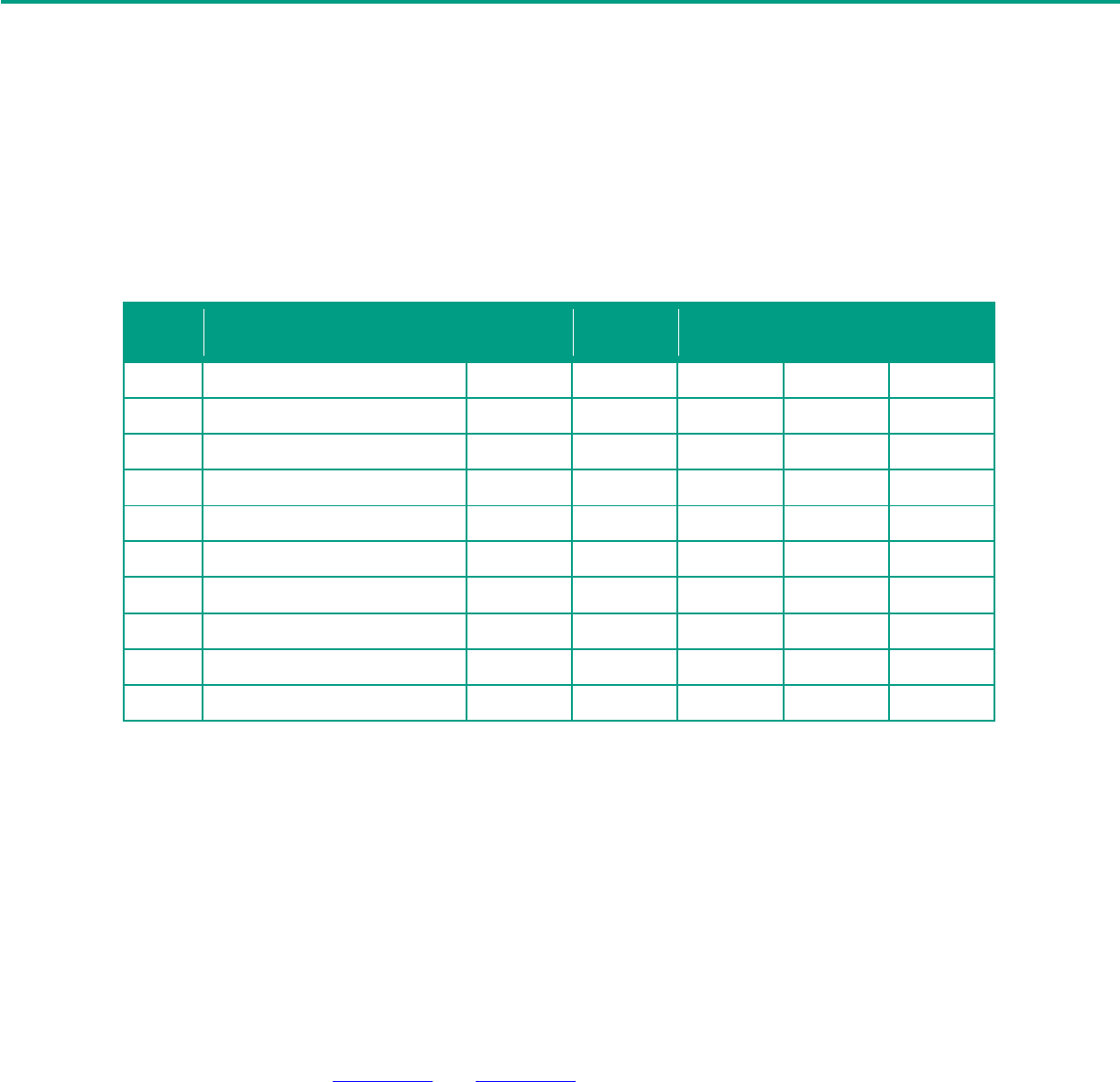

2.4.1 Prioritizing Locations to Achieve the Most Efficient Project

The efficiency of a project is assessed by the return on investment (i.e., the value achieved per

dollar spent), and the BCR is an appropriate measure to achieve the most efficient project. To

illustrate the use of BCR for achieving the most efficient safety improvement project, consider a

group of 10 potential project locations. Table 3 shows the monetary benefits, costs, NPV, and

BCR for each potential project location. Improvements are economically-justified at all potential

locations (i.e., BCR greater than 1.0 and a positive NPV). Suppose the budget for this

hypothetical systemic safety project is $80,000. Ranking the locations by BCR and NPV will

illustrate the effectiveness of each measure in developing Alternative 1 and Alternative 2,

respectively.

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE CHAPTER 2

11

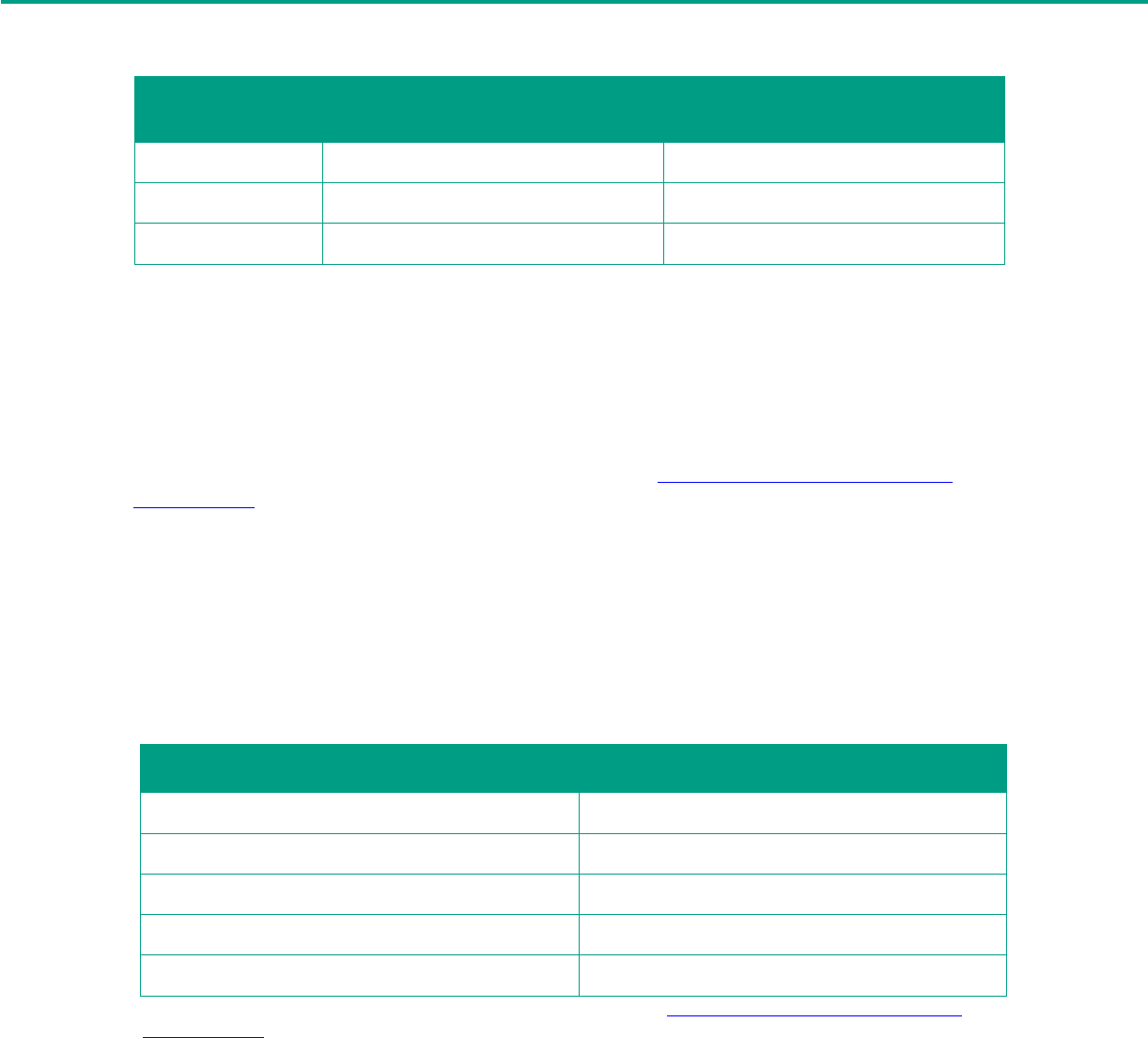

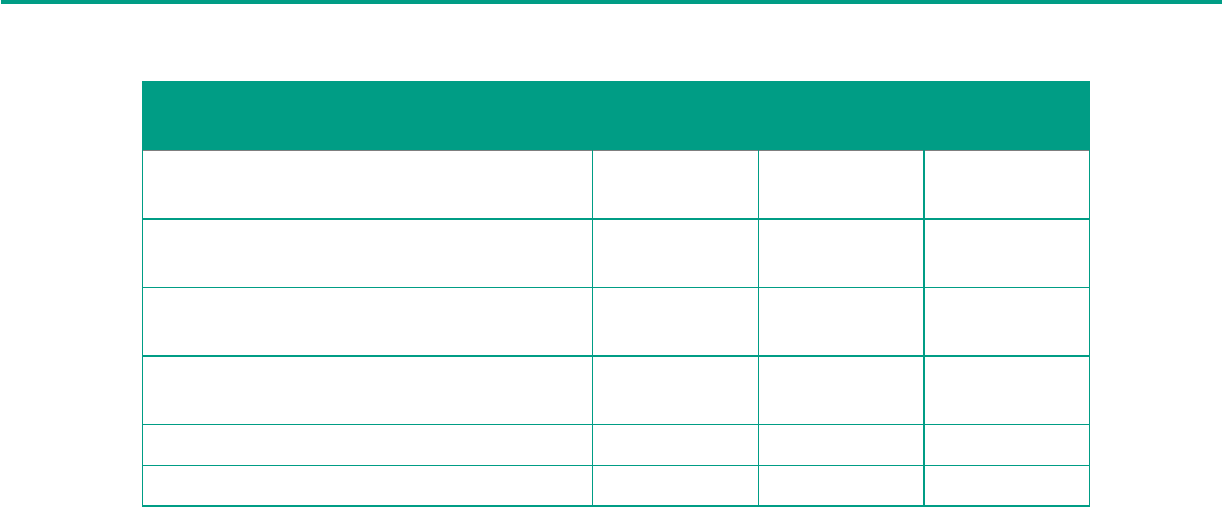

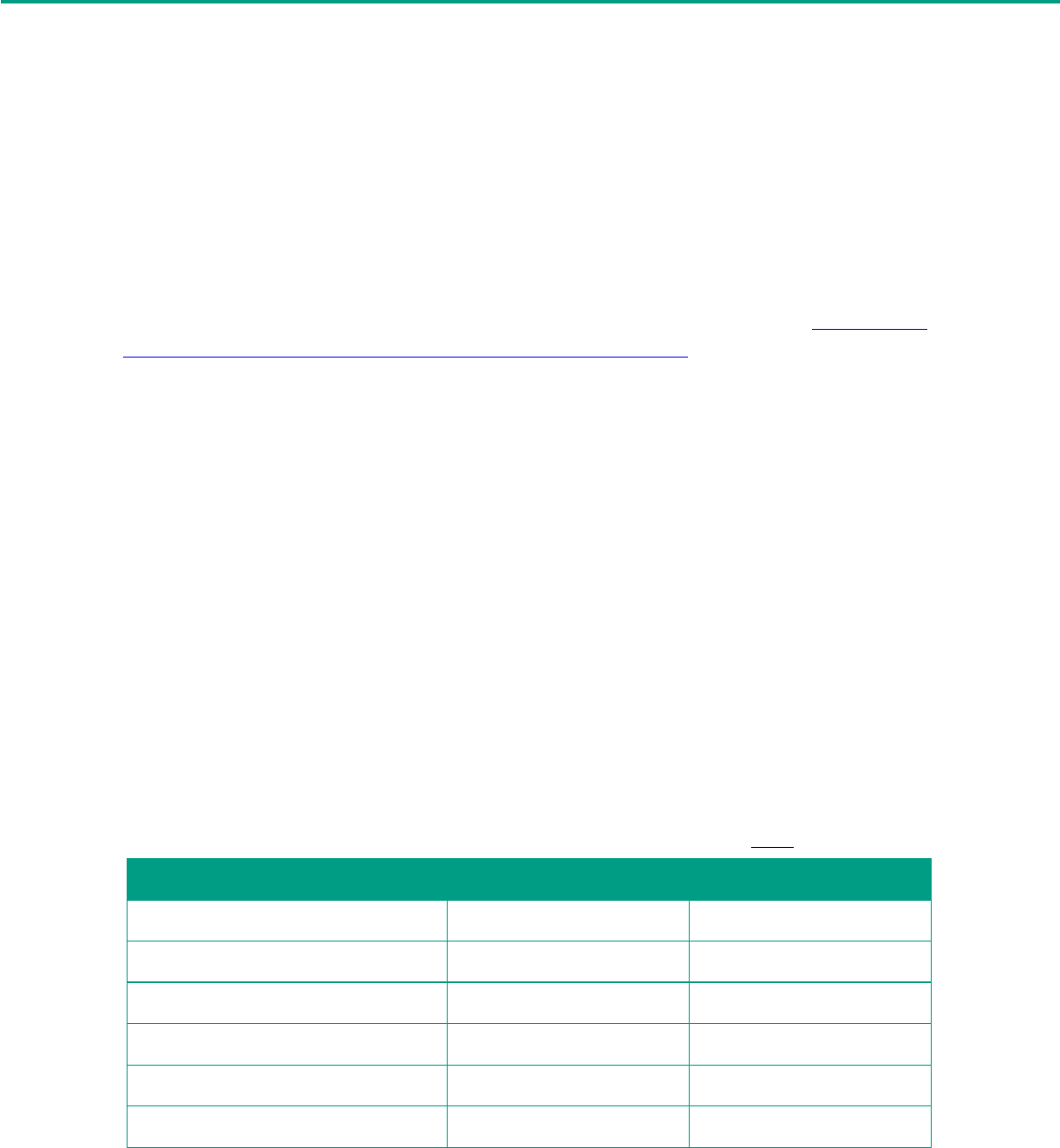

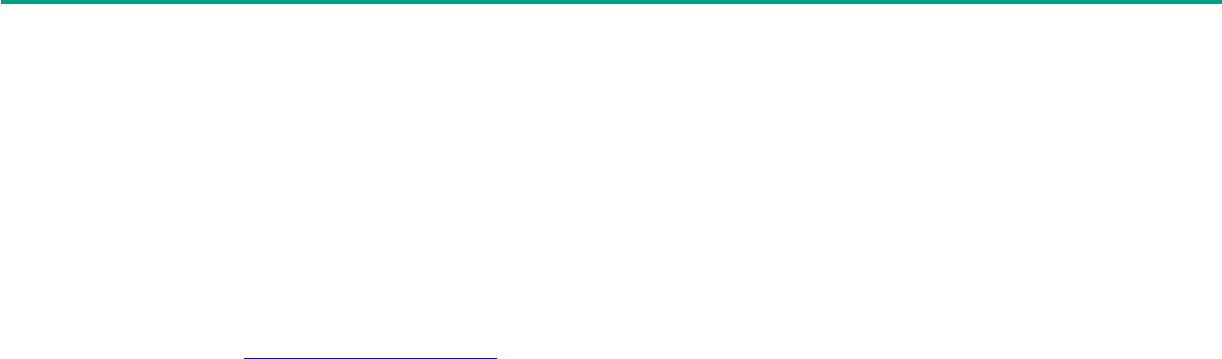

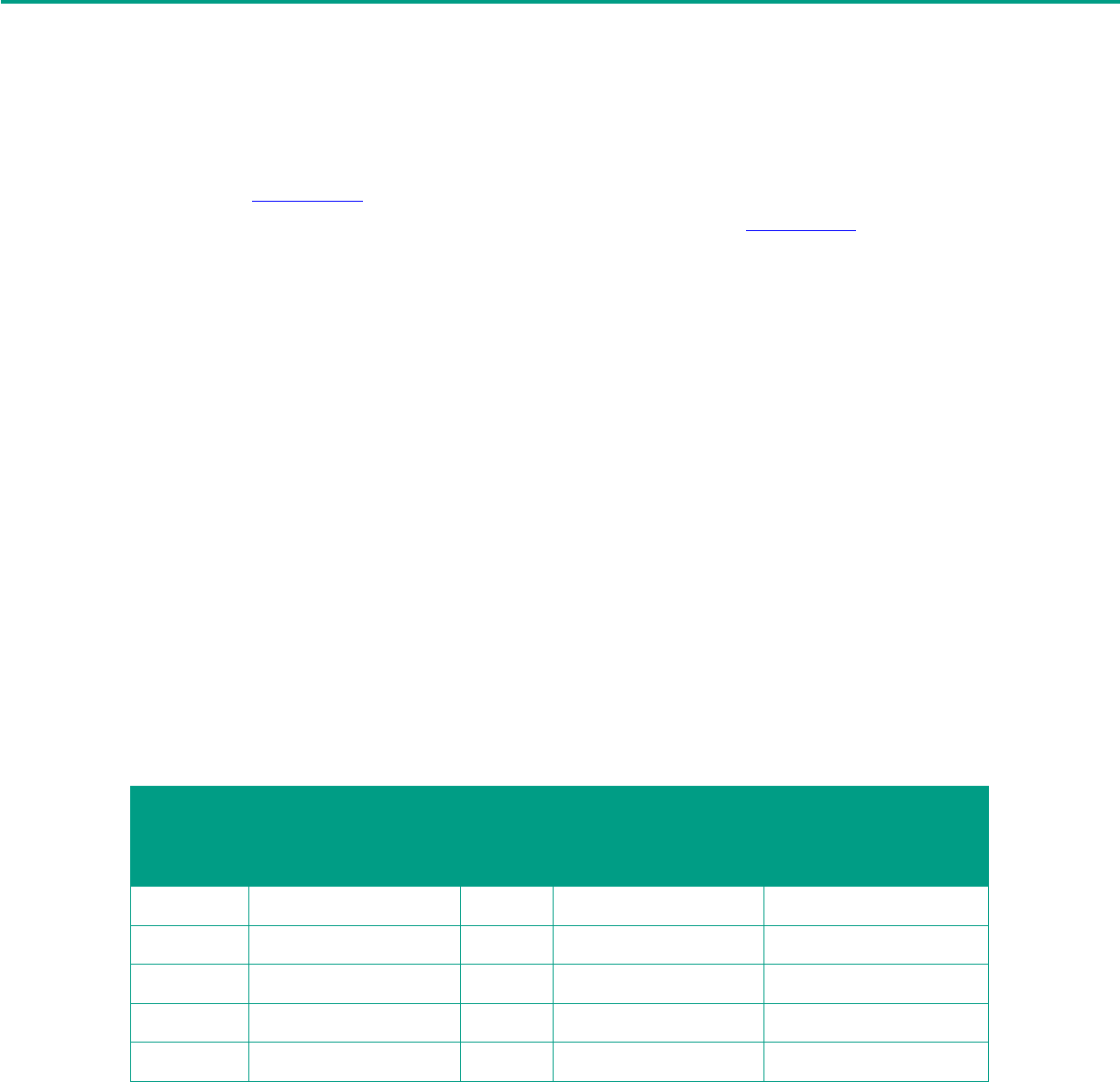

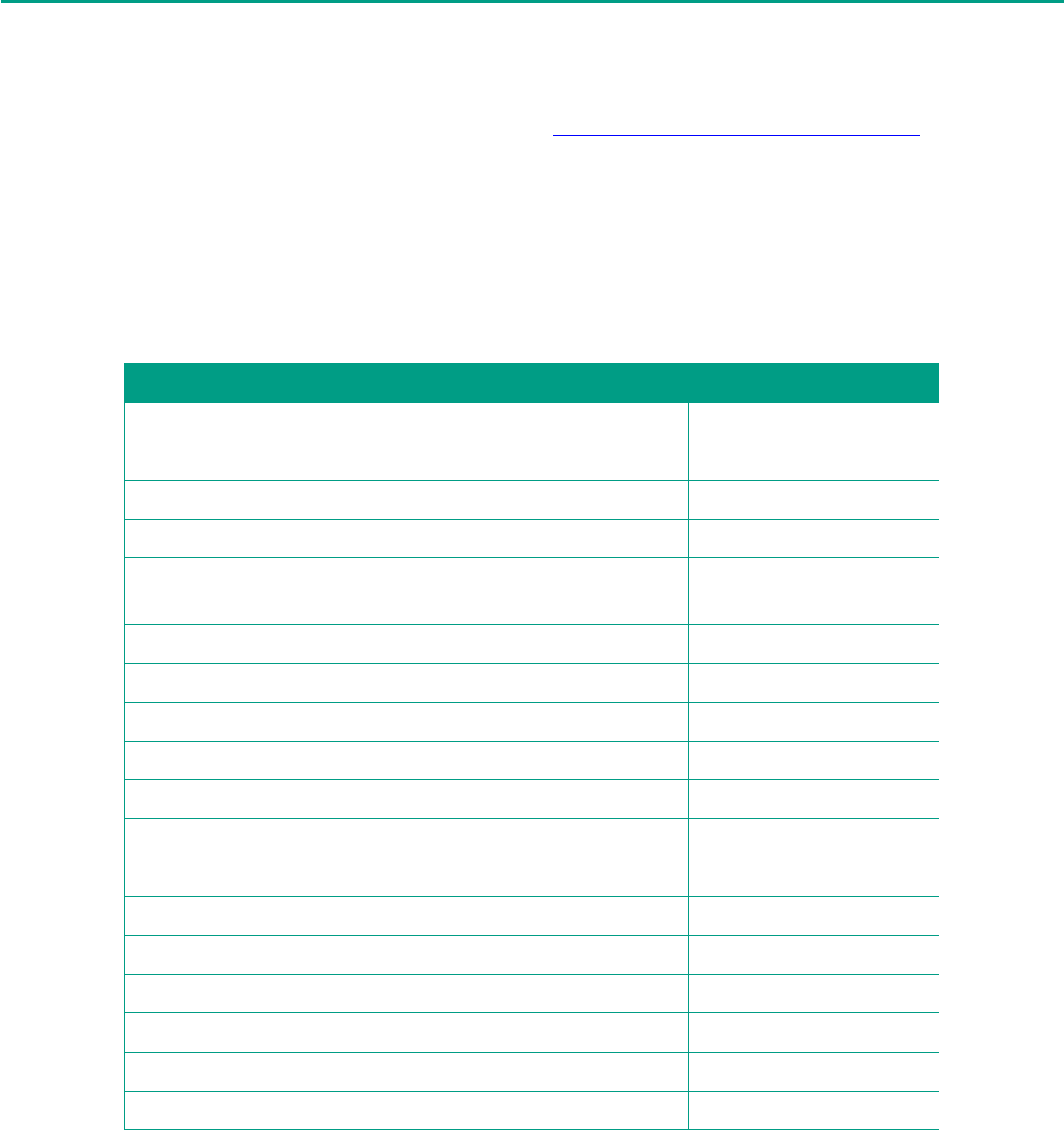

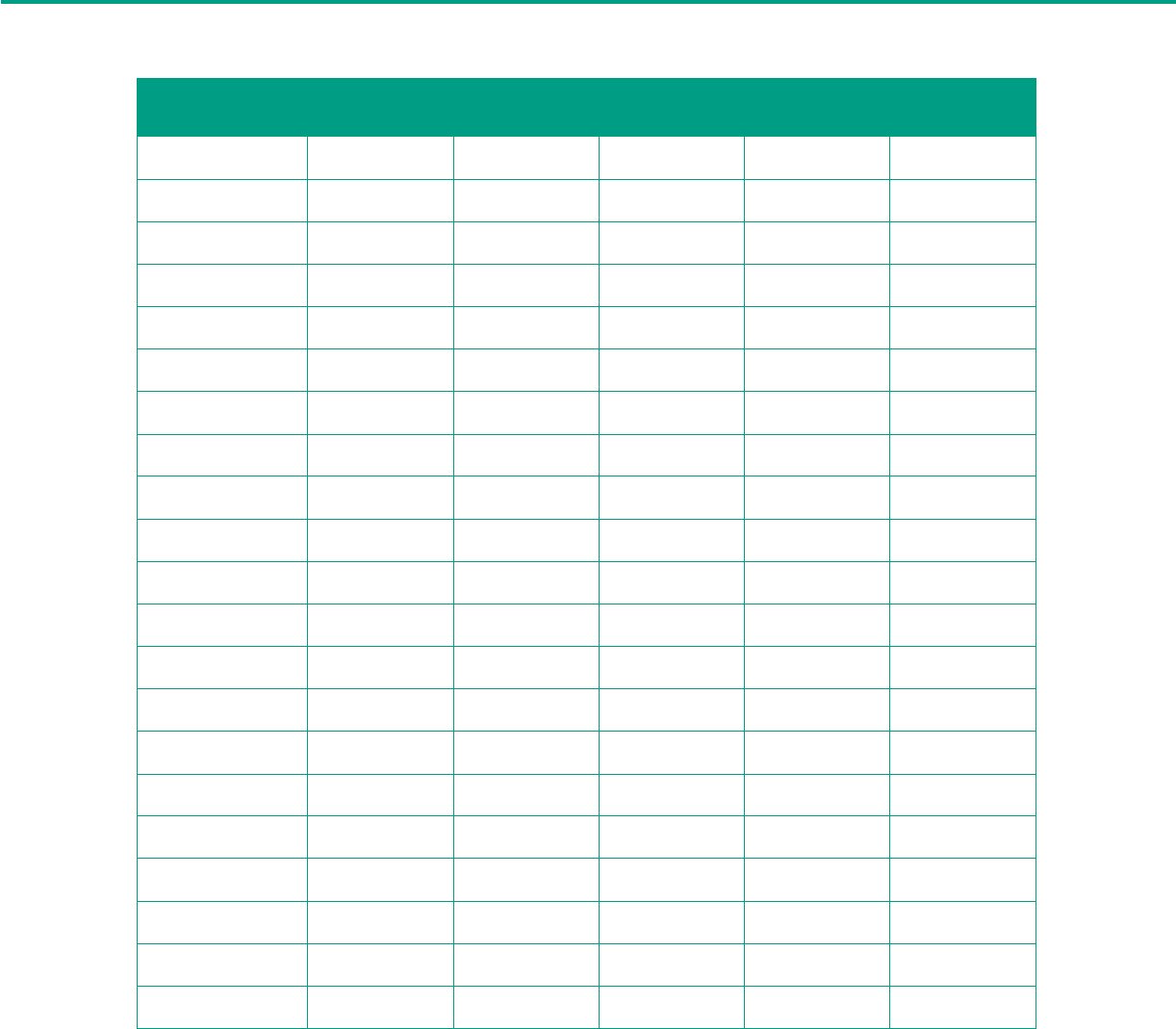

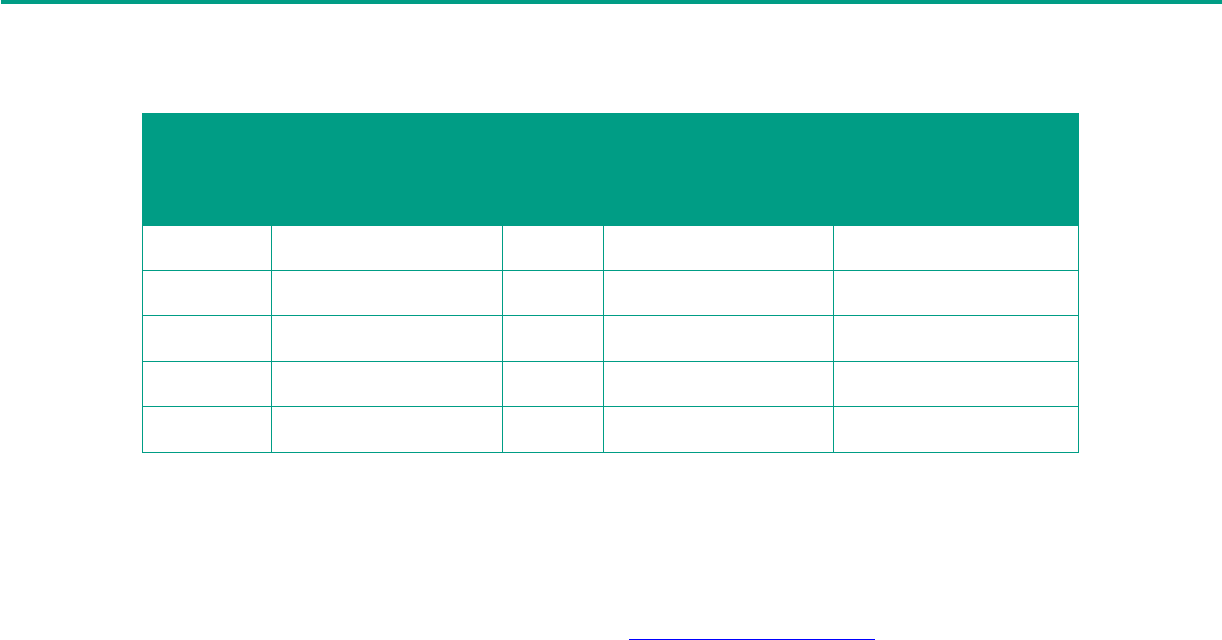

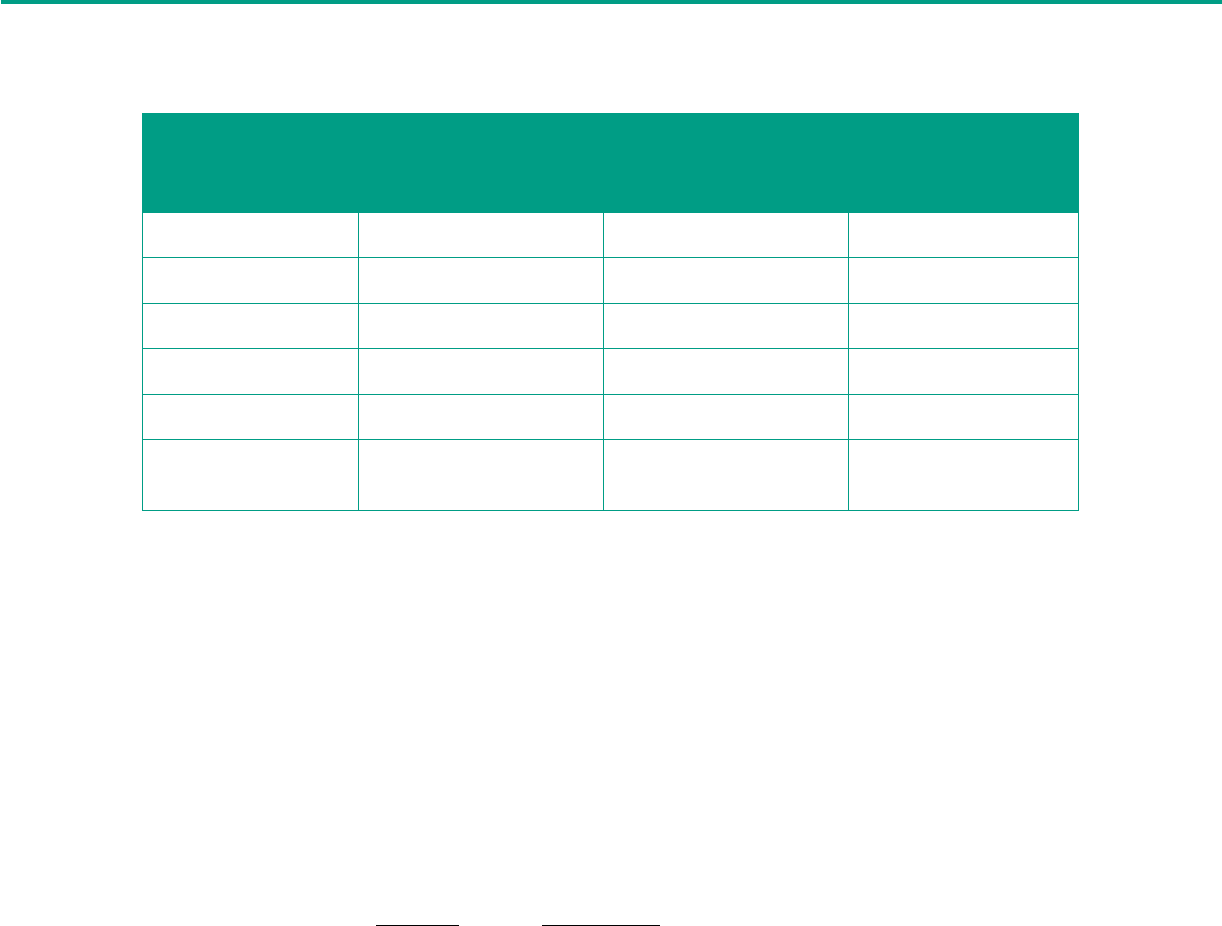

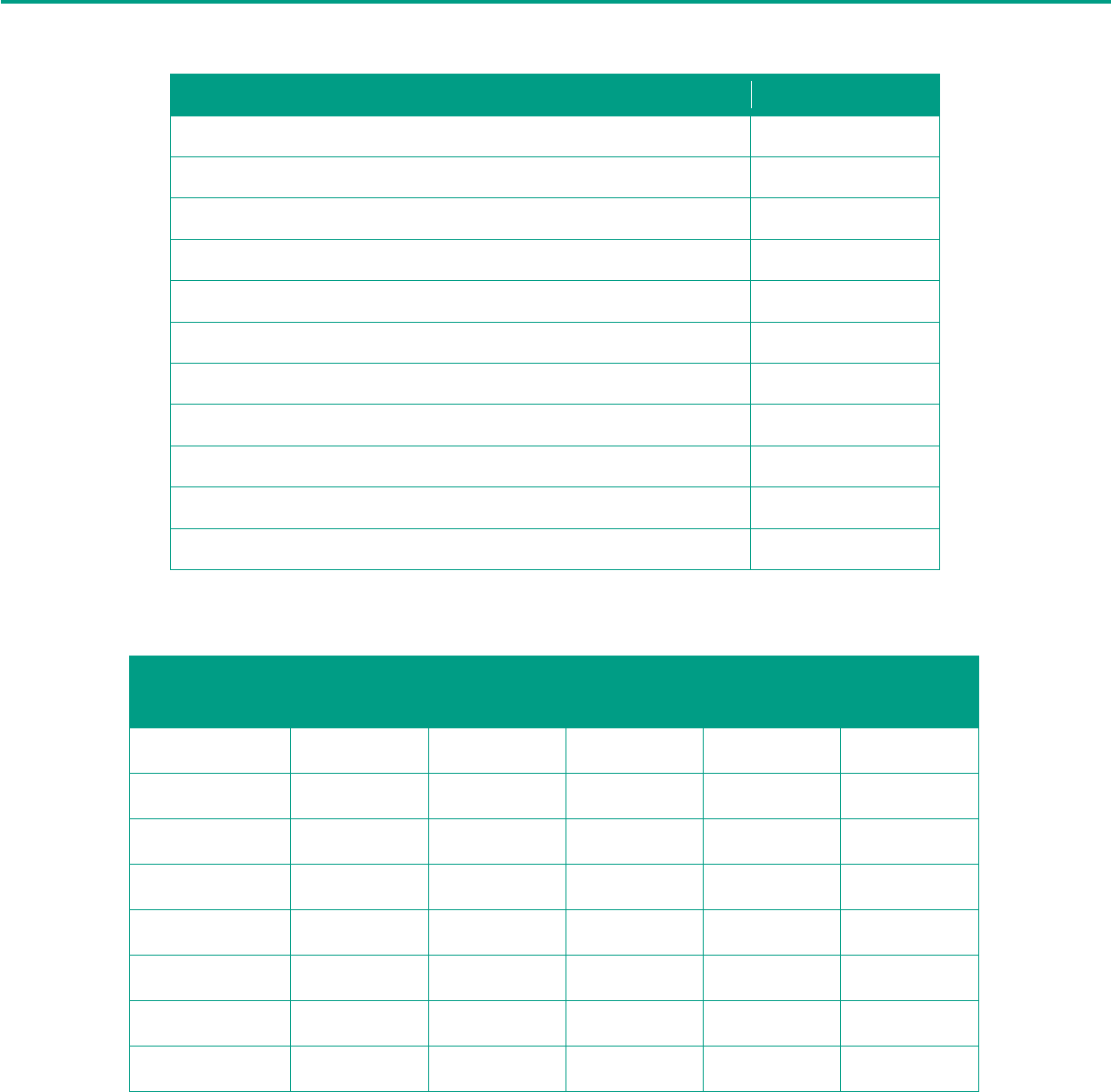

Table 3. Economic information for example project locations.

Location #

Benefits

Costs

NPV

BCR

1

$90,000

$30,000

$60,000

3.00

2

$50,000

$25,000

$25,000

2.00

3

$67,500

$20,000

$47,500

3.38

4

$100,000

$40,000

$60,000

2.50

5

$15,000

$7,500

$7,500

2.00

6

$60,000

$10,000

$50,000

6.00

7

$40,000

$10,000

$30,000

4.00

8

$25,000

$10,000

$15,000

2.50

9

$25,000

$5,000

$20,000

5.00

10

$15,000

$5,000

$10,000

3.00

Table 4 lists the priority ranking of locations by BCR. Locations for Alternative 1 are selected

from the top of the list until the budget is filled. Rows shaded gray indicate locations that do

not fit within the budget.

Table 4. BCR ranking of example project locations for Alternative 1.

Location #

Benefits

Costs

NPV

BCR

6

$60,000

$10,000

$50,000

6.00

9

$25,000

$5,000

$20,000

5.00

7

$40,000

$10,000

$30,000

4.00

3

$67,500

$20,000

$47,500

3.38

1

$90,000

$30,000

$60,000

3.00

10

$15,000

$5,000

$10,000

3.00

4

$100,000

$40,000

$60,000

2.50

8

$25,000

$10,000

$15,000

2.50

2

$50,000

$25,000

$25,000

2.00

5

$15,000

$7,500

$7,500

2.00

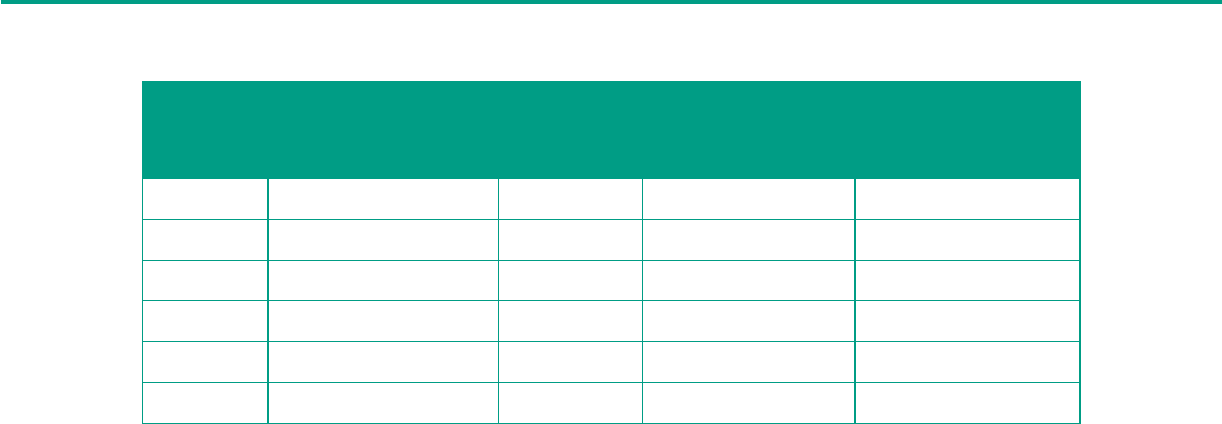

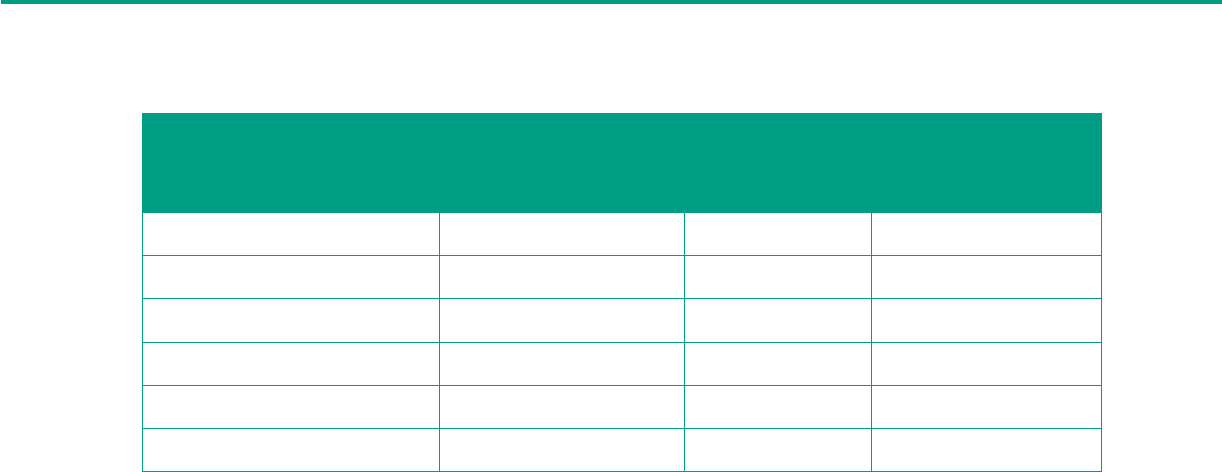

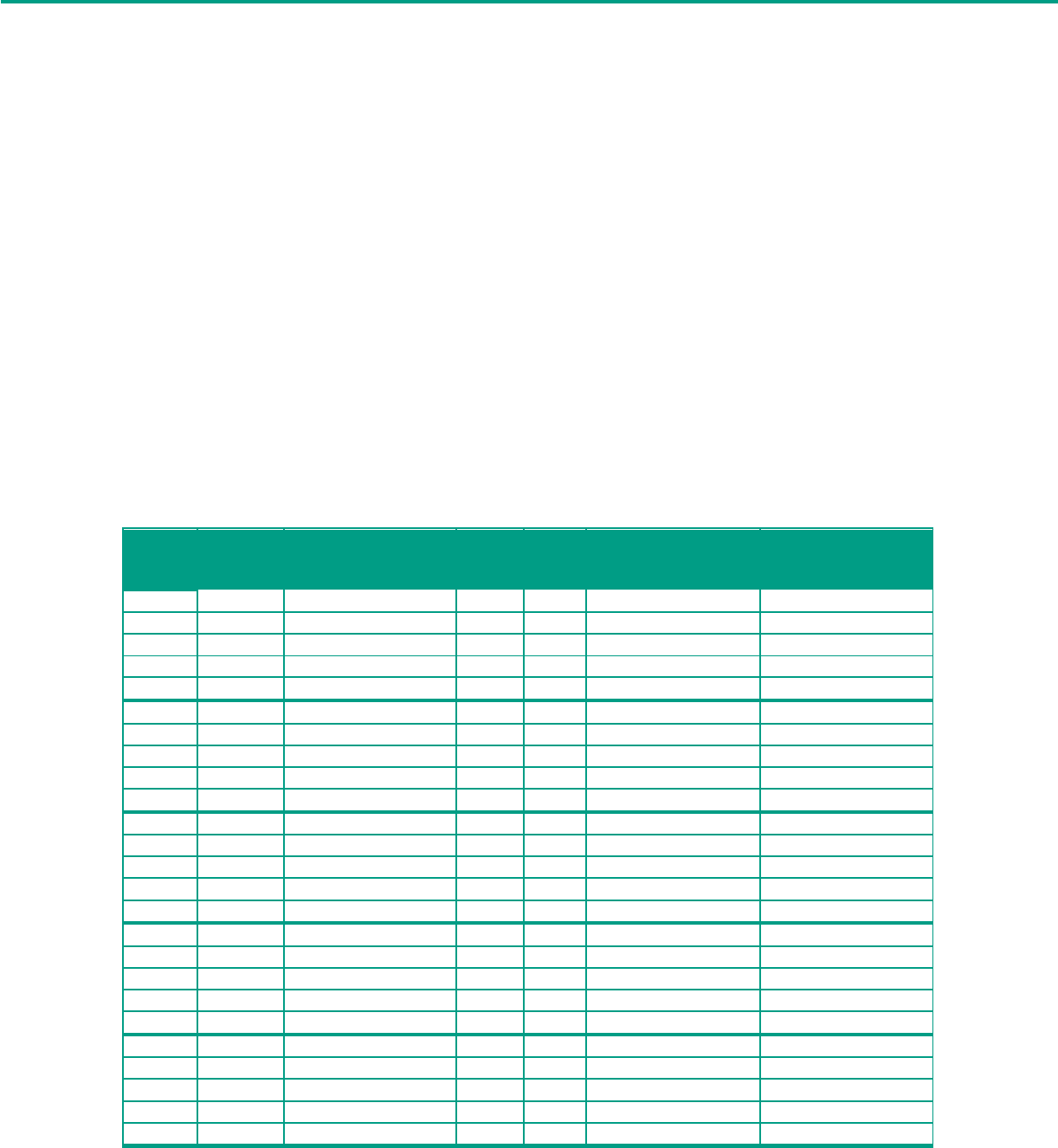

Table 5 lists the priority ranking of locations by NPV. Locations for Alternative 2 are selected

from the top of the list until the budget is filled. Rows shaded gray indicate projects that do not

fit within the budget.

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE CHAPTER 2

12

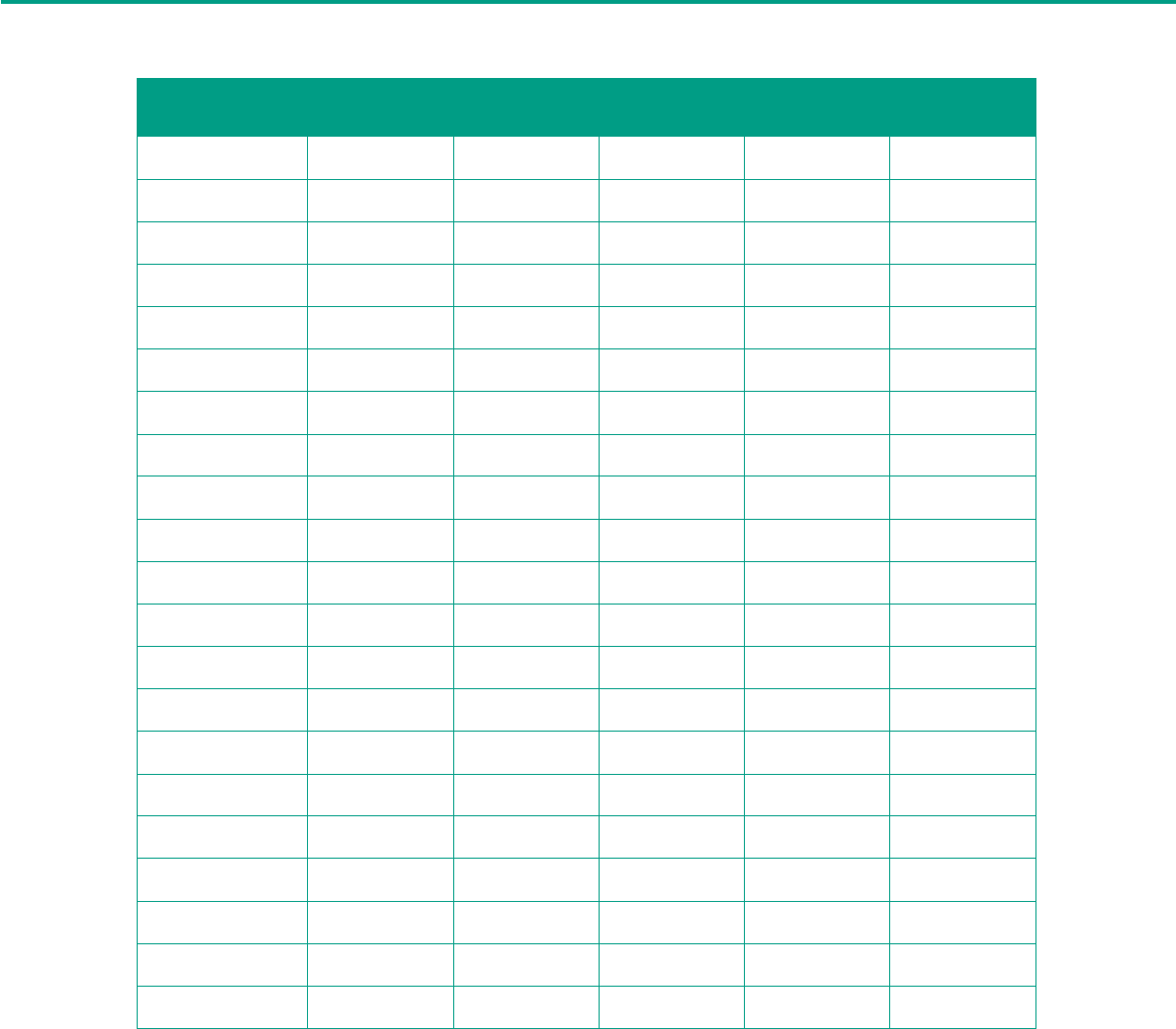

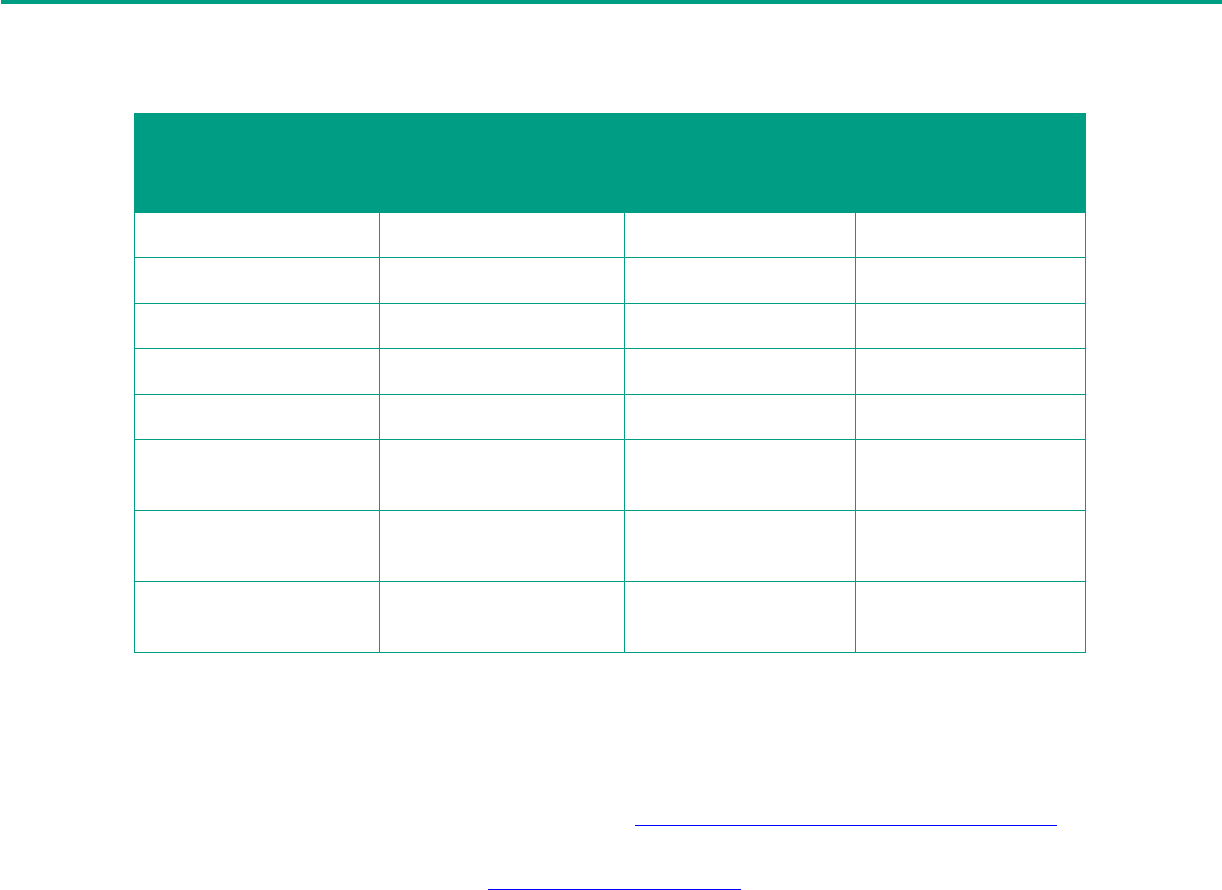

Table 5. NPV ranking of example project locations for Alternative 2.

Location #

Benefits

Costs

NPV

BCR

1

$90,000

$30,000

$60,000

3

4

$100,000

$40,000

$60,000

2.5

6

$60,000

$10,000

$50,000

6

3

$67,500

$20,000

$47,500

3.375

7

$40,000

$10,000

$30,000

4

2

$50,000

$25,000

$25,000

2

9

$25,000

$5,000

$20,000

5

8

$25,000

$10,000

$15,000

2.5

10

$15,000

$5,000

$10,000

3

5

$15,000

$7,500

$7,500

2

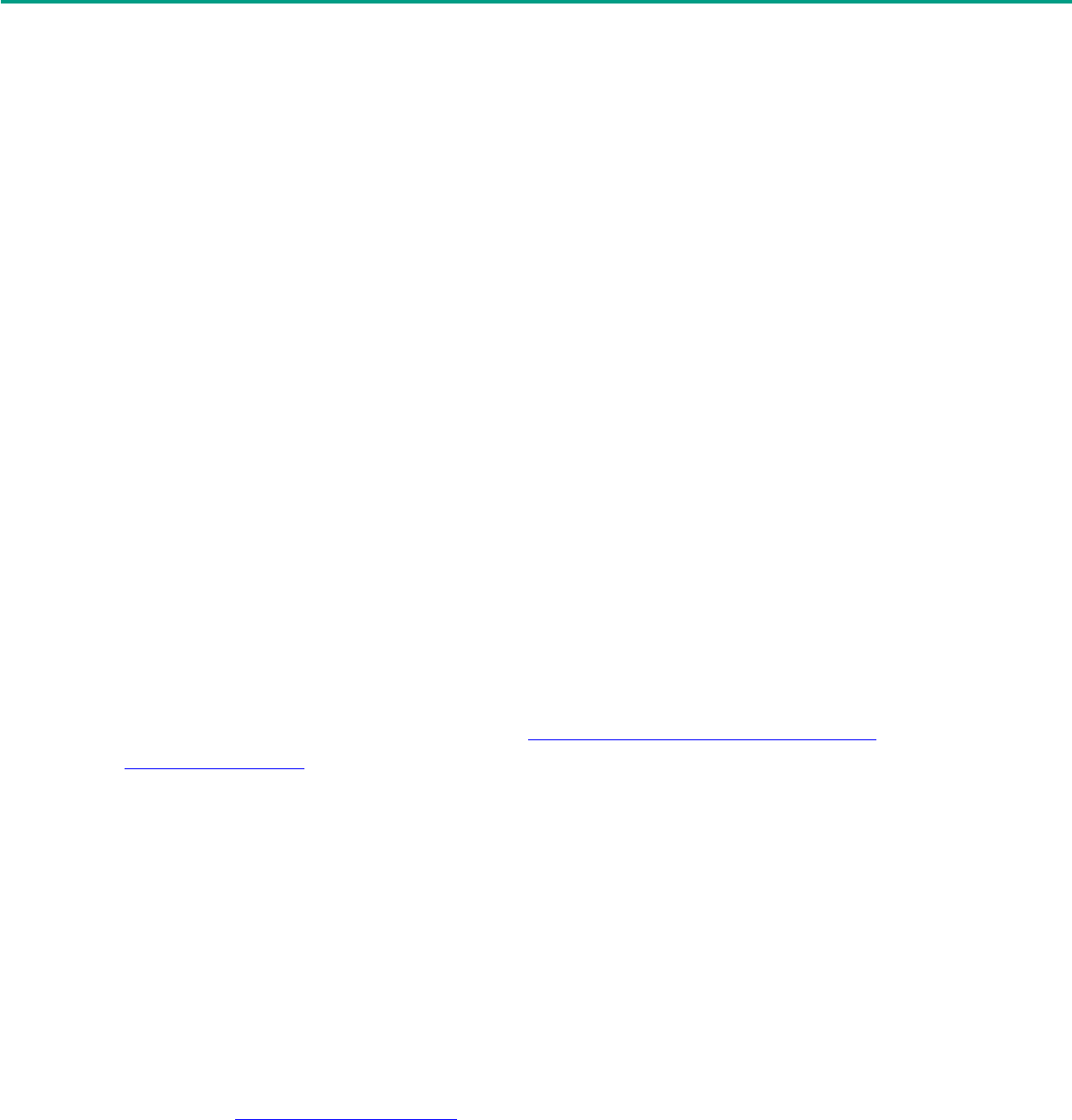

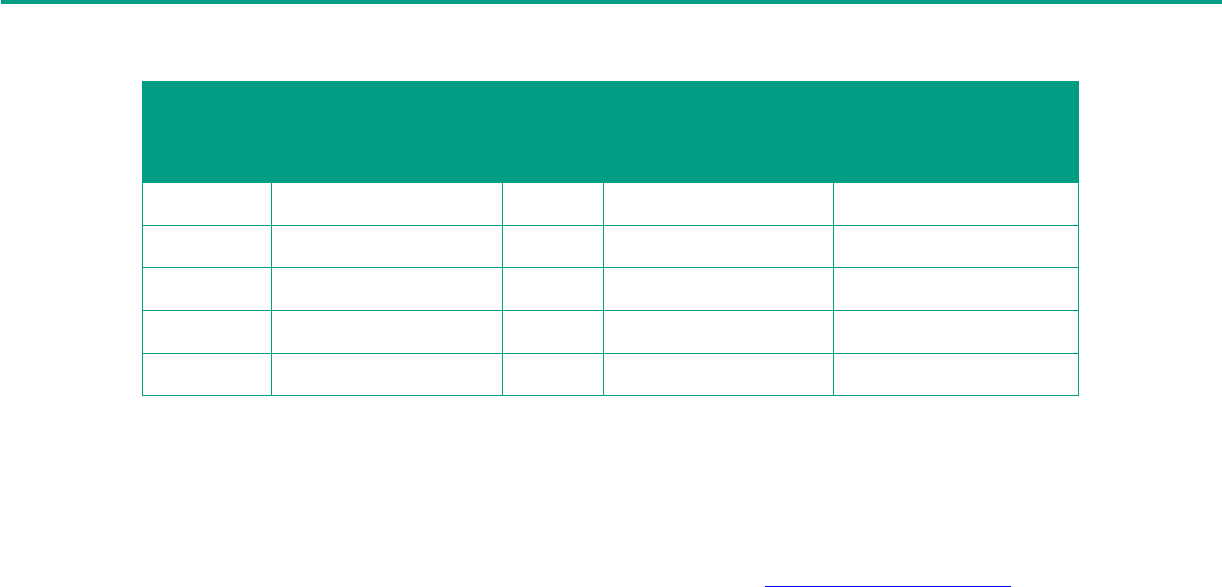

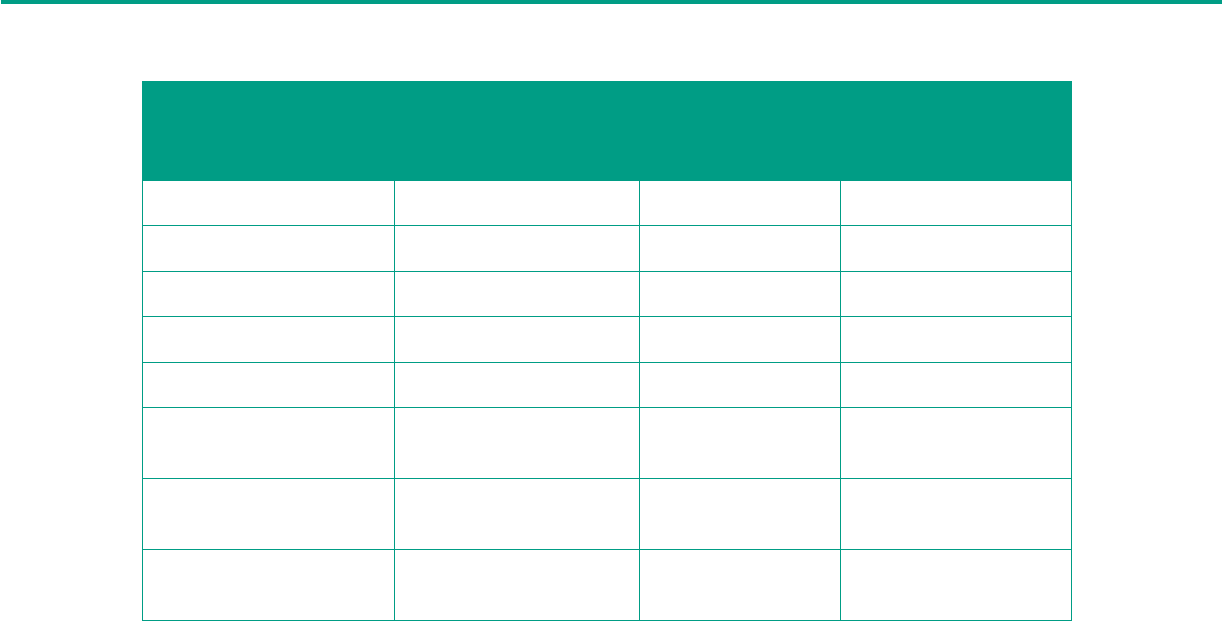

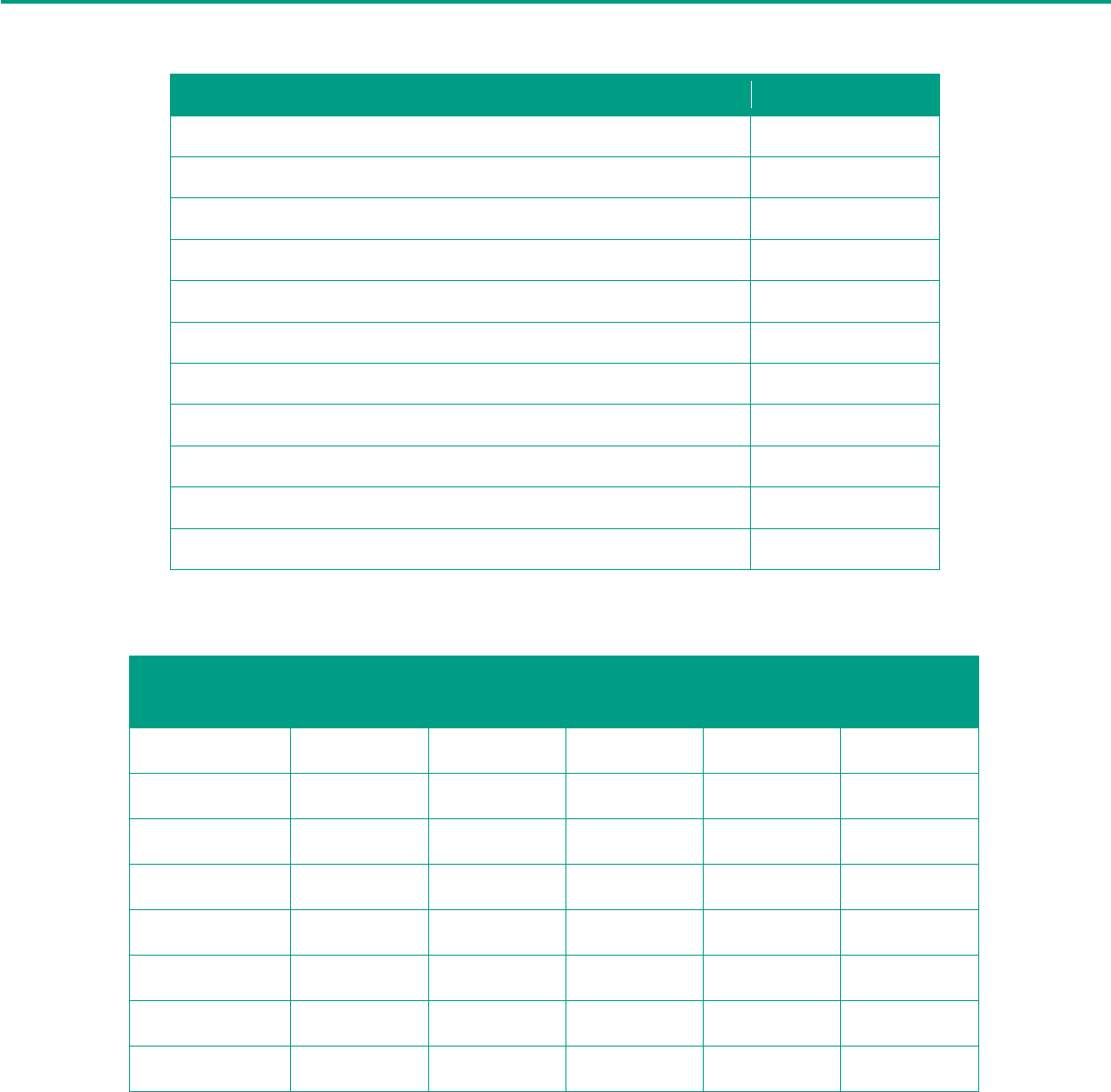

Table 6 provides a comparison of the economic measures for selected locations in Table 4 and

Table 5, representing Alternative 1 and Alternative 2, respectively. Bold numbers indicate the

preferred alternative. Alternative 1, developed using the BCR, is clearly the preferred set of

locations as it provides the highest benefits, NPV, and BCR. Alternative 1 provides the most

efficient project because it results in the greatest benefits within a fixed cost.

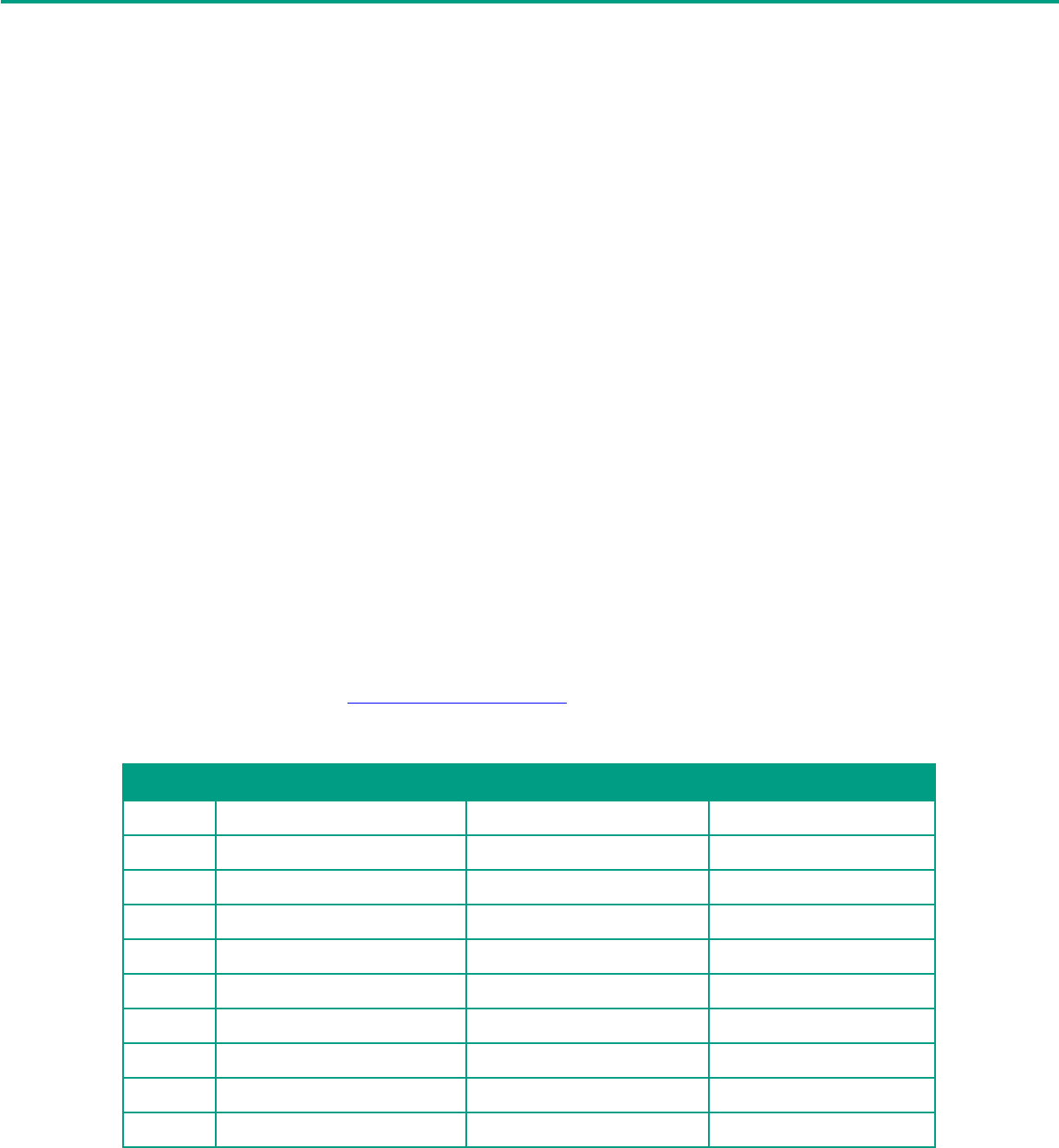

Table 6. Alternative 1 and Alternative 2 economic comparison.

Economic Measure

Alternative 1

Alternative 2

Total Benefits

$297,500

$250,000

Total Costs

$80,000

$80,000

NPV

$217,500

$170,000

BCR

3.72

3.13

2.4.2 Prioritizing Locations to Determine the Most Effective Project

The effectiveness of a project is assessed by the overall benefits (i.e., the total value achieved),

which is indicated by the highest NPV. When the budget of a project is fixed, and assuming that

funds are expended up to the budget limit, the most efficient project is also the most effective.

Again, the BCR is an appropriate measure to achieve the most efficient and effective project

given a fixed budget. This section describes how to achieve the most effective project without

consideration of budget.

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE CHAPTER 2

13

While prioritizing potential locations using BCR yields the most efficient (cost-effective) project,

in some cases agencies and the public may desire an economically-justified project with the

highest possible benefits, regardless of the cost-efficiency of the investment. For example,

stakeholders may call for additional spending to provide the greatest possible crash reduction at

a high-profile site with an extraordinary crash history. The most cost-effective alternative may

provide only a marginal reduction in crashes. Additionally, given the BCR ranking can favor a

larger number of smaller-scale improvements at multiple locations, some agencies may decide

to pursue fewer, more effective improvements to reduce the burden of project management.

Prioritization by NPV yields a ranking of maximum benefits in each alternative. However, as

illustrated in the previous section, ranking by NPV can reduce the cost-effectiveness of the

overall project and can guide funds towards less efficient investments. When selecting the most

effective alternative with NPV, agencies may be ignoring the most cost-effective alternatives

(i.e., the funds could have been spent on more efficient projects). If there were no budgetary

limitations, NPV is the preferred prioritization measure.

2.4.3 Prioritizing Project Locations Without Monetized Benefits

In some scenarios, the monetary value of benefits cannot be determined or is not used in

analysis. For example, if the severity distribution of the expected crash reduction is not well

known, an agency may not be comfortable applying average crash costs to estimate the

monetary benefits. In this case, the CEI is a suitable measure for prioritizing project locations.

This measure incorporates the monetary costs with non-monetary benefits (i.e., change in the

number of crashes). The CEI does not allow for direct consideration of non-safety benefits.

2.4.4 Optimizing Project Locations within a Program

Optimization is the process of organizing prioritized projects within program budget limitations

and other constraints to maximize program effectiveness over time. Optimization methods use

mathematical models to maximize the benefits of projects, both monetary and non-monetary,

without exceeding the available budget. Optimization occurs after the initial economic analysis

and includes only those projects that are economically-justified. As such, it does not affect the

procedures described in the previous sections.

There are several optimization methods with various capabilities and constraints, including

linear programming, integer programming, and dynamic programming. These methods are

consistent with maximizing the BCR of a safety program. Integer programming is the most

applicable to project optimization, where each project is either implemented or not. Refer to

the Highway Safety Manual for further discussion of optimization methods.

(7)

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE CHAPTER 2

14

2.5 HIGHWAY SAFETY BCA RESOURCES

In addition to this Guide, the FHWA and State transportation agencies have produced

numerous technical references relating to BCA. This section provides an overview of selected

resources.

2.5.1 Highway Safety Manual

The Highway Safety Manual presents a science-based technical approach to conduct safety

analysis for transportation facilities, including methods to predict the change in crashes resulting

from the implementation of safety countermeasures.

(7)

The Highway Safety Manual provides

methods for developing an effective roadway safety management program and evaluating its

effects. The Highway Safety Manual provides tools to conduct quantitative safety analyses,

allowing quantitative evaluation of safety alongside other transportation performance measures

such as traffic operations, environmental impacts, and construction costs. The target audience

of the Highway Safety Manual is a wide audience of transportation professionals at the State,

county, metropolitan planning organization (MPO), or local level.

The Highway Safety Manual includes an overview of BCA in Chapter 7, Economic Appraisal. In

addition, the Highway Safety Manual provides predictive methods to estimate crash frequency

and severity. The user can employ these methods to estimate predicted or expected crashes

for use in BCA.

2.5.2 Crash Costs for Highway Safety Analysis

The Crash Costs for Highway Safety Analysis guide describes the various sources of crash

costs, current practices and crash costs used by States, critical considerations when modifying

and applying crash unit costs, and an exploration of the feasibility of establishing national crash

unit cost values.

(10)

The guide proposes a new set of national crash unit costs and procedures to

1) update the crash unit costs over time, and 2) adjust the crash unit costs to States based on

State-specific cost of living, injury-to-crash ratios, and vehicle-to-crash ratio. This BCA guide

and the related tool incorporate the suggested national crash unit costs as default values.

2.5.3 The Economic and Societal Impact of Motor Vehicle Crashes

The National Highway Traffic Safety Administration (NHTSA) published this study in 2014, later

revised in 2015, representing the most recent research on the fiscal impact of motor vehicle

crashes. The Economic and Societal Impact of Motor Vehicle Crashes presents the results of

this research, quantifying the economic and societal costs resulting from motor vehicle crashes

recorded in 2010.

(11)

The costs include aggregate increases in air emissions, vehicle operating

costs, and travel time that result from crashes. This report provides perspective on the

economic losses and societal harm that result from crashes, and supports government and

private sector officials in structuring programs to reduce or prevent these losses. This BCA

Guide uses results from the NHTSA report to monetize project benefits and externalities.

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE CHAPTER 2

15

2.5.4 Economic Analysis Primer

USDOT developed the Economic Analysis Primer to provide a foundation for understanding

the role of economic analysis in highway decision-making.

(8)

The Primer is oriented toward State

and local officials who have responsibility for assuring that limited resources get targeted to

their best uses and who account publicly for their decisions. It presents economic analysis as an

integral component of a comprehensive infrastructure management approach that takes a long-

term view of infrastructure performance and cost. The primer is nontechnical in its descriptions

of economic methods, but it encompasses a full range of economic issues that are of potential

interest to transportation officials. This BCA Guide briefly describes the use of the discount

rate and risk analysis in highway safety BCA. Refer to the Primer for further details on these

and other fundamental economic analysis concepts.

2.5.5 Operations Benefit/Cost Analysis Desk Reference

The Operations Benefit/Cost Analysis Desk Reference provides background information on

BCA, including basic terminology and concepts.

(1)

The reference supports the needs of

practitioners, new to BCA, who may be unfamiliar with the general process. The reference

describes some of the more complex analytical concepts and latest research to support

transportation professionals in conducting more advanced analyses. This BCA Guide focuses on

the safety impacts of projects. If a safety project is also likely to impact operations, refer to the

Operations Benefit/Cost Analysis Desk Reference to consider additional benefits. Some of the

more advanced topics include capturing the impacts of travel time reliability, assessing the

synergistic effects of combining different strategies, and capturing the benefits and costs of

operations-supporting infrastructure such as traffic surveillance and communications.

2.5.6 Life-Cycle Cost Analysis Primer

This BCA Guide focuses on the comparison of both project benefits and costs in selecting and

prioritizing alternatives. Lifecycle cost analysis (LCCA) is an approach used to compare the

costs of project alternatives, assuming the agency has decided to implement a project at a given

location. Analysts should only use LCCA to compare project alternatives that would yield the

same benefits. For example, LCCA would be an appropriate tool to compare two alternative

bridge replacement designs that would result in the same level of service. Refer to the Life-

Cycle Cost Analysis Primer for further details on the use of LCCA in the evaluation of

alternative infrastructure investments.

(12)

The Primer demonstrates the value of such analysis in

making economically-sound decisions.

2.5.7 Benefit-Cost Analysis Guidance for TIGER and INFRA Applications

The Benefit-Cost Analysis Guidance for TIGER and INFRA Applications combines and expands

previous guidance provided for TIGER and FASTLane grant applications.

(13)

There are several

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE CHAPTER 2

16

inputs to BCA and this BCA Guide provides default values where appropriate; however, funding

programs often require specific values for parameters such as the discount rate, value of

statistical life, and value of time. The guidance provides technical information that grant

applicants need for monetizing benefits and costs for their (required) project BCA, as well as

guidance on BCA approach.

The appendices provide recommended monetary values and sample calculations.

(13)

One

appendix provides supplemental information, standard monetized values (where available), and

updates for preparing a BCA. The second appendix provides computational examples and

guidance on conducting an analysis. This guidance also refers to the Office of Management and

Budget (OMB) Circulars A-4 and A-94 in preparing analyses compliant with federal law.

2.5.8 Highway Safety Improvement Program Manual

The Highway Safety Improvement Program (HSIP) Manual describes the overall program

established by FHWA and the methods for developing a roadway safety management program

that focuses on results by emphasizing a data-driven, strategic approach to improving highway

safety through infrastructure-related improvements.

(14)

The HSIP Manual describes laws and

regulations, new and emerging technologies, and noteworthy practices for each of the HSIP’s

four basic steps: analyze data, identify potential countermeasures, prioritize and select projects,

and determine effectiveness. This reference is intended for State and local transportation safety

practitioners working on HSIPs and safety projects. The manual is useful in describing how BCA

fits into a transportation agency’s overall (federally-mandated) HSIP and the need for BCA in

the project prioritization process (Chapter 4 of the HSIP Manual).

2.5.9 Crash Modification Factor Clearinghouse

The BCA Guide and Tool incorporate the use of crash modification factors (CMFs) to estimate

safety benefits. The CMF Clearinghouse is a comprehensive and searchable database of

published CMFs for hundreds of different types of safety countermeasures.

(15)

Analysts use

CMFs to estimate expected changes in crash frequency and severity from implementing one or

more countermeasures. The Clearinghouse contains all CMFs published in the first edition of

the Highway Safety Manual as well as many CMFs published or documented in other sources.

The Clearinghouse provides information on available CMFs such as the CMF value, general

applicability, citation, and quality rating. The Clearinghouse provides links to additional

resources to assist CMF Clearinghouse users who are interested in obtaining guidance on other

topics related to CMFs such as how to select an appropriate CMF, how to apply CMFs, and

how to develop CMFs.

HIGHWAY SAFETY BENEFIT COST ANALYSIS GUIDE CHAPTER 2

17

2.6 CHAPTER SUMMARY

Chapter 2 describes fundamental concepts in BCA and safety management. It begins with an

overview of BCA and the types of costs (design, construction, operations, and maintenance)

and benefits (user benefits and externalities) included in BCA. It describes the safety

management process, including two complementary approaches to safety management: crash-

based and systemic. Next, the chapter defines several economic measures for use in project

decision-making. This is followed by a discussion of the role of BCA in safety management. The

chapter concludes with a description of several technical references for conducting highway

safety BCA.

Key Takeaways from Chapter 2:

• BCA is a systematic process for calculating and comparing benefits and costs of a

project.

• A BCA analyzes project costs (agency costs), project benefits (user benefits), and

externalities (non-user benefits) to compare alternatives.

• Project costs include the costs to design, construct, operate, maintain, and rehabilitate

the project.

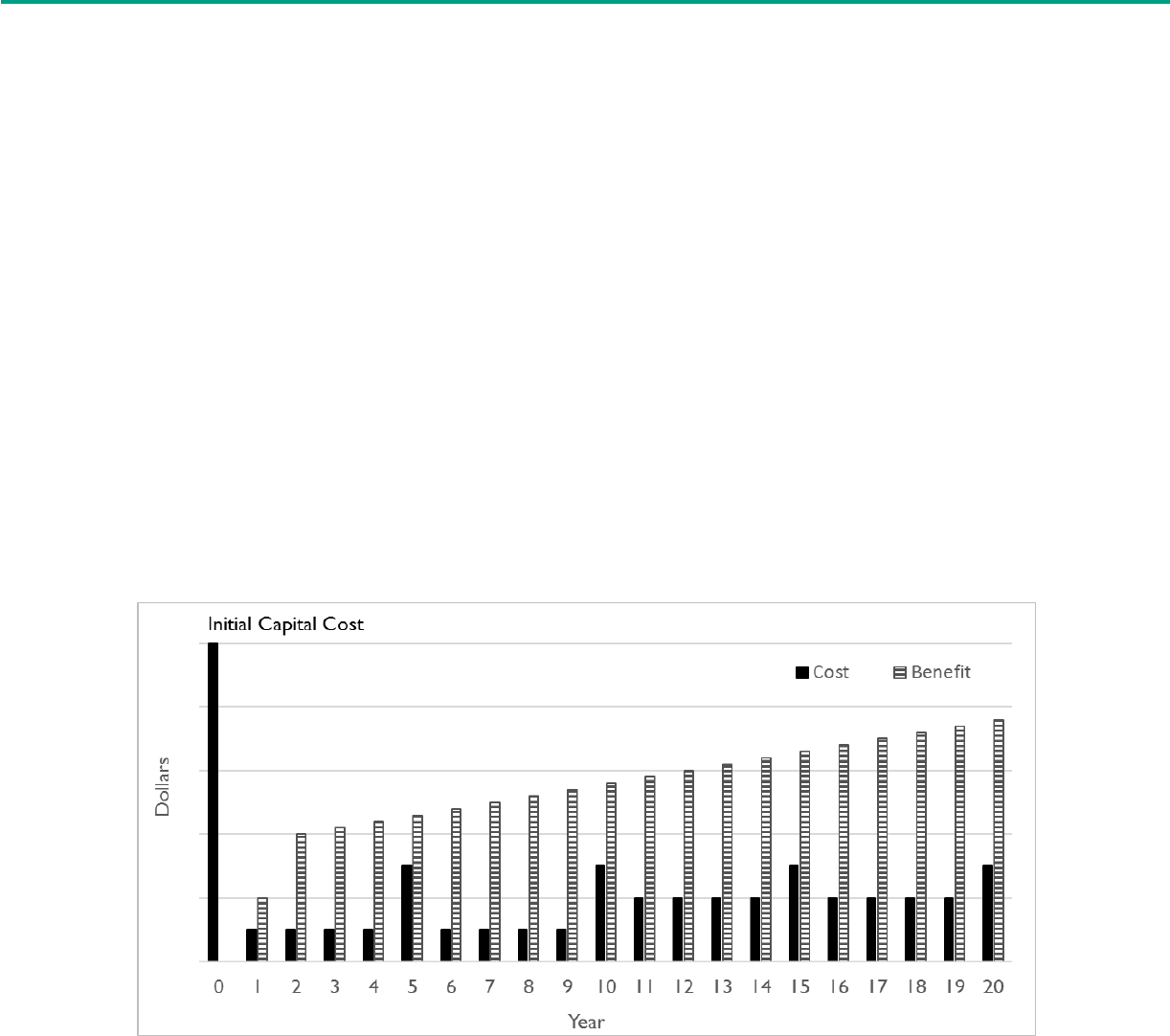

• Project benefits include all benefits to users or society such as reduced crash frequency