1

REPORT OF ACCIDENT TO VT-EQL CHETAK HELICOPTER OF BSF AT FATEHPUR VILLAGE,

NEAR MOUNT ABU, RAJASTHAN ON 13.05.2011

(a) Helicopter

Type and Model : Chetak Helicopter

Nationality : Indian

Registration : VT-EQL

(b) Owner/Operator : Border Security Force,

New Delhi

(c) Date of Accident : 13.05.2011

(d) Time of Accident : 0945 UTC

(e) Last Point of Departure : BSF base, Gandhinagar, Ahmedabad

(f) Point of intended Landing : Mandore, Jodhpur, Rajasthan

(g) Geographical Location of : Lat. 24˚32’33” N

Accident Long. 72˚38’35” E

(h) Type of Operation : Non-scheduled

(i) Phase of Operation : Cruising

(All Timings in the Report are in UTC)

2

SYNOPSIS

Border Security Force (BSF) Chetak Helicopter VT-EQL met with an accident

while operating flight from Gandhinagar to Mandore on 13.05.2011 at Fatehpur

village, near mount Abu, Rajasthan.

The accident was investigated by Committee of Inquiry appointed under Rule

74 of Aircraft Rules, 1937; vide Govt of India, Ministry of Civil Aviation,

Extraordinary Gazette Notification No. AV, 15013/003/2011-DG dated 26

th

July

2011.

The helicopter took off from Gandhinagar, Gujarat at time 0850UTC for

operating flight to Mandore, Rajasthan with a Pilot in Command (PIC), a co-pilot,

one Engineer and a BSF Official on board. The flight was uneventful from

Gandhinagar till the time (0940 UTC) it was in contact with Ahmedabad ATC.

While it was flying through Aravali hills range near Mt. Abu, it developed serious

defect in the Main Rotor System. Helicopter was on radial R- 007 at Fatehpura

Village in Rajasthan.

Before impacting the ground the helicopter made a right turn and impacted the

ground with high impact force. The crash site is approximately 40 metres away

from the route as per the flight plan filed by the helicopter. Helicopter impacted

the ground squarely i.e. vertically with no forward movement. It crashed and

caught fire. All the occupants were charred to death inside the burning helicopter.

The accident was caused by the loss of rotor pitch control resulting from

probable failure of Hydraulic Drag Dampers in flight which imposed excessive

tensile load on the Blade Spacing System. One of the Attachment Bolts sheared off

and released one Spacing Cable. The second bolt gave way and the associated Link

opened up, thereby releasing the second Spacing Cable end from the same post.

The severed Spacing Cable Eye-end impacted and broke the pitch control rods

leading to the loss of control of the helicopter.

3

1.1 History of Flight

Border Security Force (BSF) Chetak Helicopter VT-EQL met with an

accident at Fatehpur village, near Mount Abu, Rajasthan, while operating flight

from Gandhinagar, Gujarat to Mandore, Rajasthan at 0945 UTC on 13.05.2011.

There were four persons on board which included Pilot in Command, Co- Pilot,

one Engineer and a BSF Official.

The Crew of the helicopter filed Flight Plan for direct routing from

Gandhinagar to Mandore for an altitude of 1500 ft AGL. The telephonic clearance

was taken from Area Control land line for a VFR flight. The Helicopter departed

from Gandhinagar at 0850 UTC. ATC advised the pilot of the helicopter VT-EQL to

maintain the preferred altitude of 1500 feet AGL on QNH 1005 hpa.

He was further advised to report 30 miles out. Pilot intimated estimates

as FIR 1030 UTC and ETA destination 1155 UTC. Then the estimates were passed

on to FIC at 30 miles. ATCO directed the pilot of the helicopter to change over to

the frequency 123.75 MHz as the pilot did not reply, ATCO requested another

aircraft to intimate VT-EQL to establish contact with Control on 123.75MHz.

Soon after, the pilot was heard calling on 123.75 MHz. After being released by

Approach Control, Pilot reported his position 30 NM from AAE 1500 feet on QNH

1005 HPA. He did not report any abnormality in operations of helicopter. The

helicopter remained in contact with ACC on frequency 123.75 MHz till 0907 UTC

reporting at 30NM on radial 007 AAE. At time 0908 UTC the helicopter called Jet

Airways Aircraft 2065 to relay the position of 30NM on radial 007 AAE to

Ahmedabad ACC. On Route Radar, the helicopter painted till 0911 UTC and then

the target dropped off at a distance of approx 37 NM from AAE.

The Chetak helicopter VT-EQL was on route R007 from South to North and

developed serious defect in Main Rotor System. As reported by the Eye-witness,

a local farmer, sitting outside his hut and having direct view of the helicopter, the

helicopter was producing intermittent hitting sound. After passing over the hut,

it executed a sudden right turn and fell squarely on the ground and burst into

4

flames. The adjacent area and the bushes started burning and fire engulfed the

area of the accident site. His statement was corroborated by another farmer

sitting near his hut about 100 metres away from the accident site. The first Eye-

witness immediately intimated the local Police Station on his mobile phone about

the accident. The Police and Fire tender reached the site of the accident within

half an hour and spread foam and water on the burning helicopter. All the

occupants of the helicopter i.e. pilot, co-pilot, AME and the BSF Official, got burnt

inside the helicopter. The accident took place during the day time at 0945 UTC.

5

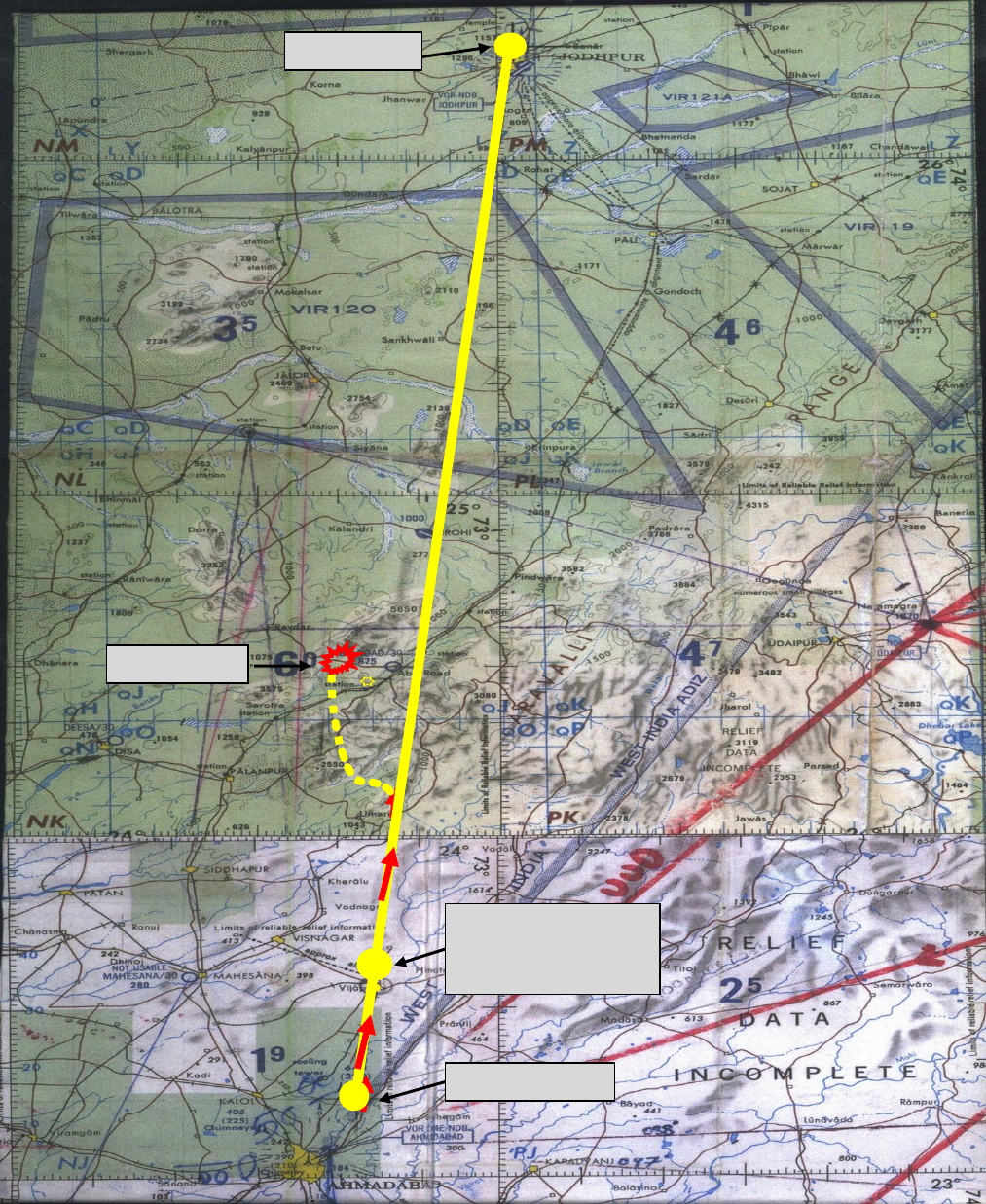

Fig.1Topographic chart showing the VT-EQL departure site, the accident site,

the destination and the Route cleared for.

GANDHINAGAR

We are reporting 30

miles on R-007, 1500ft

QNH 005

CRASH SITE

MANDORE

6

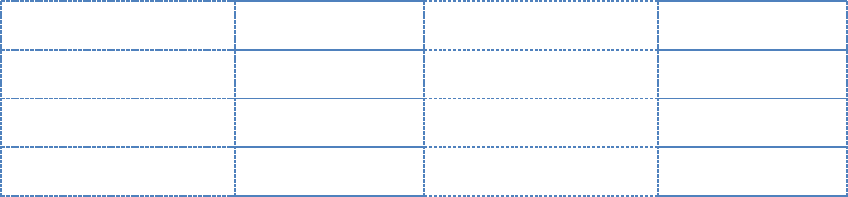

1.2 Injuries to Persons

INJURIES

CREW

PASSENGERS

OTHERS

FATAL

2

2

NIL

SERIOUS

0

0

NIL

MINOR

0

NIL

NIL

1.3 Damage to Aircraft

Helicopter was completely destroyed due to impact and fire.

1.4 Other Damages

Nil

1.5 Personnel information

1.5.1 Pilot-in-Command

Details of Licence

License type : CHPL-758

Valid up to : 18-04-2012

Date of Issue : 19-04-2007

Date of Endorsement

on type of Aircraft being flown : 19-04-2007

Date of Last Medical : 23/12/2010

Date of Birth : 12-10-1961

Details of last two IR check : IR no-229 Last IR done on 17

th

Dec 2009 on Bell-212

Skill Test : ST done on 5

th

Nov 2010 on Chetak.

ST done on 17

th

Dec 2010 on Chetak

7

Aircraft Ratings

As PIC : Allouette III/Chetak, Bell 212

As Co-pilot : Allouette III/Chetak, Bell 212

Flying Experience:

Total Flying Experience : 2930:00 Hrs

Flying during last 90 days : 19:15 Hrs

Flying during last 30 days : 19:15 Hrs

Experience on type : 1781:00 Hrs

Flying during last 7 days : 04:00 Hrs

During last 24 hours : Nil

He was not previously involved in any accident/serious incident.

1.5.2 Co-Pilot

License Details:

License type : CHPL NO 919

Valid up to : 11-02-2014

Date of Initial Issue : 12-02-2009

Date of Endorsement on

type of Aircraft being flown : 12-02-2009

Date of Birth : 09-05-1977

Date of Last Medical : 18/01/2011

PC checks : 30

th

April 2010,

27

th

Jan 2011

8

Aircraft Ratings:

As PIC : 68:40 hrs on Chetak

As Co-pilot : 78.05 hrs on Chetak

Flying Details : Dual – 99:15 hrs

PIC-68:40 hrs

Co-pilot – 78:05 hrs

Total Flying Experience : 246:00 hrs

Experience on type : 246:00 hrs

Flying during Last One year : 59:20 hrs

Flying during 30 days : 22:55 hrs

Flying during last 7 days : 02:30 hrs

During last 24 hours : Nil

He was not previously involved in any accident/serious incident.

1.5.3 Aircraft Maintenance Engineer

Licence type : A&C

Date of Issue : 29.06.1990

Date of Endorsement of

Aircraft type : Alloutte III B, Artouste III B, Cheetah/ Lama

/ Approval/Authorisation

Experience on type : January 1996 to 13

th

May, 2011

9

1.6 Helicopter Information

1.6.1 Helicopter Information

Manufacturer

Helicopter Division, Hindustan Aeronautics

Limited, Bangalore

Type

Chetak Helicopter

Constructors S.NO.

AH-303

Year of Manufacturer

1989

Certificate of Airworthiness

No. 1924, Date of Initial issue.28.11.1988

Currently Valid up to 03-04-2012

Category

Normal

Sub Division

Private

Certificate of Registration

No. 2431/2, Issued on 11/10/1990

Owner (with Address)

Director General, Border Security Force, ‘F’

Wing Hall, Nirman Bhawan, New Delhi

Minimum Crew Required

One

Maximum Authorised All Up

Weight

2200 Kgs.

Last Major Inspection

100 hrs on 21/03/2011

Last Inspection

25 hrs on 16/04/2011

Air frame Hrs. Since New

4019 :20 hrs. (up to 10/05/2011)

Air frame Hrs. Since last C of A

43 hrs 55 minutes

10

Engine

Single

Manufacturer

Turbomecca / HAL Engine Division

Type

Artouste-III B

Serial No.

H-55484

TSO

432 hrs. 40 minutes

Last Inspection Carried Out

25 hrs on 16/04/2011

Last Major Inspection Carried

out

100 hrs/180 days inspection on 21/03/2011

Average Fuel Consumption

182 kgs/hr (as on 09/02/2011)

Average Oil Consumption

45.313 mg /hr (as on 09/02/2011)

1.6.2 Scrutiny of records

The last major inspection 100 hrs/180 days was carried out on 21

st

March, 2011

at 3975.35 A/F hrs. The helicopter had flown 43 hrs 20 minutes after this

inspection till the day of accident.

The Vertical stabilizer was replaced with new one on 6

th

January, 2011, due to

suspected crack in the removed stabilizer.

No significant snag had been recorded on this helicopter since its last C of A

renewal i.e. on 4

th

April, 2011 except a snag about the RPM indicator not

registering at Gandhinagar, Ahmedabad. The RPM indication snag was rectified

by re-soldering connector wires as the same was found to have come out of the

connector. The standard troubleshooting procedure was not followed. The RPM

indicator was found recording the RPM satisfactorily on ground run given at

Gandhinagar prior to take off from BSF helipad.

The Scrutiny of old records revealed that the helicopter was involved in Tail hit /

heavy landing on 30

th

January, 2005. On 29

th

Jan, 2005 crew had reported “severe

11

vertical and lateral vibrations”. As a rectification, drag dampers were checked for

play, MGB, transmission platform and main rotor head mounting, spacing cable

along with bolt and the links were also checked. The helicopter after this

inspection reported vibrations at high speed and high collective pitch. Necessary

rectification action was carried out on drag dampers. On 30

th

January, 2005,

during vibrex check severe vibrations were encountered and helicopter made a

emergency landing about half a kilometre from the Mandore helipad. During

inspection, following damages were observed:

Spacing cable Attachment bolt had sheared off on the yellow sleeve

of the main rotor head.

Spacing cable end had become free and impacted the trailing edge

of red main rotor blade at about 12 inches from blade root and

caused damage to trailing edge 10 inches in length and 5 inches in

width.

Following the incident, Main Gear Box (Serial No. CH435), Main

Rotor Shaft (Serial No. AH 184), Free Wheel and Drive Shaft

Assembly (CH211), Clutch Unit (Sr.No. 402) and Hydraulic Drag

Dampers were sent to HAL for heavy landing checks. It is found that

two separate Defect Reports have been raised by the maintenance

agency for the removal of drag dampers.

a) DIR dated 10.05.2005, which states that Hydraulic Drag Damper Sr.

No CH 802, CH1779, CH1780 were replaced as their calendar life

was near to completion.

b) DIR dated 11.05.2005, which states that Hydraulic Drag Dampers

Sr. No CH 924, CH925, CH926 were replaced for onward dispatch to

HAL for inspection after heavy landing made by the helicopter on

30

th

Jan, 2005. The on numbers were CH733, CH734, and CH735.

However these Sr. No(s) are not available in the Inventory of BSF.

12

On 23/12/2008 Hydraulic Drag Damper Sr. No CH 924, CH925,

CH926 were replaced due “Timing out of limits”.

As per log cards of hydraulic drag dampers Sr. No CH 802, CH 1779, CH

1780 were installed on 22/12/2008. These were overhauled at HAL on

06/12/2005 and matched. Thereafter, there is no record of

replacement of the drag dampers.

Drag dampers Sr. No CH 802, CH 1779 matched with the drag

dampers recovered from the accident site. However, the Serial No. of

the third drag damper could not be identified as its body had burnt.

1.6.3 General Description

The Chetak helicopter is a three bladed lifting rotor with an anti torque tail rotor

powered by Turbomeca Artouste IIIB Turbo shaft engine developing 550 S.H.P. at

33,500 R.P.M. The fuselage comprises of two distinct assemblies, the body

structure and the tail boom. The Main Rotor has three foldable, metal covered

blades that are articulated on the hub by means of horizontal and vertical pins.

The equal spacing among the Main Rotor Blades is maintained by three spacing

cables and three hydraulic drag dampers. The anti torque tail rotor is mounted

on the starboard side at the end of the tail boom. The engine output shaft, the

speed of which is already stepped down to 5770 R.P.M. by the engine reduction

gear, drives the main rotor at 355 R.P.M. through the Main Gear Box. The Main

Rotor collective and cyclic pitch variation is controlled through a Swash Plate

assembly. The helicopter has conventional cockpit.

The Main Rotor System consists essentially of Hub which carries three

Main Rotor Sleeves. The blade pitch change is controlled by means of rods

connected at one end to the Blade Horns carried by the Blade Sleeves and at the

other end to the Rotating Star/Upper Swash Plate.

13

The Flapping hinge is designed to limit the bending loads applied at the blade

roots as a result of the lift forces acting on the blades. The drag hinge is designed

to limit the bending loads applied at the blade roots as a result of Coriolis

acceleration forces. Oscillations are dampened by means of three Hydraulic

Dampers mounted on the vertical drag hinge pin.

Blade Link is a steel forging with two holes at right angles to each other. The

horizontal hole allows vertical movement about the hub through flap hinge pin.

Horizontal movement of the blade spindle is achieved through the drag hinge pin

fitted in the vertical hole.

Main Rotor Head Operation:

A. Centrifugal loads resulting from the rotation of the blades are carried by

the Tension-Torsion strips in the blade sleeve.

B. If, during rotor operation, the horizontal motion of a blade is disturbed,

two distinct components are used to overcome the disturbance.

The cable spacing equalizer system corrects transient disturbance affecting inter

blade spacing to ensure proper 120° angular distribution among the three blades.

The Hydraulic Drag Dampers limit the horizontal oscillations of the blade by

taking up the loads developed about the drag hinge axis and so facilitate the

action of the blade spacing cables.

C. In the event of vertical flapping being set up, it is automatically

aerodynamically damped by the attendant Coriolis forces.

D. Through contact of their restrained ring, the Centrifugal Droop Restrainers

prevent the blades from the drooping low, when the blades are at rest or rotating

at low speed.

14

1.6.4 Load and Trim Sheet

There were four persons onboard including the crew. 309.6 kg. (400 lt.) of fuel

was uplifted at Ahmedabad. Total fuel on board was 565 lt. at take-off. Trim was

within limits.

1.7 Met Information

1.7.1 Met Report from Ahmedabad Airport (Just Before Take-off)

Time : 0840 UTC

S/WIND : VRB/2 kts

Visibility : 6 km.

Clouds : NSC

Temp. : 39 deg. C

Dew Point : 16

QNH : 1005 hPa 2968 INS

QFE : 998 hPa 2949 INS

Trend : NOSIG

1.8 Aids to Navigation

N/A

15

1.9 Communication

ATC Communication record of Ahmedabad

The start up was approved by Area control (ACC) at 084815 UTC. The PIC

was advised to contact at frequency 119.8 MHz after getting airborne. At 085848

UTC, Area communicated to FIC the airborne time as 0850, FIR estimate was

given as 1030 UTC and ETA Mandore as 1155 UTC. At 085326 UTC the helicopter

VT-EQL established contact with TAR controller at frequency 119.8 Mhz. At

085519 UTC, the helicopter was cleared to climb to 1500 ft and further advised to

report after reaching the altitude. At 085528 UTC the helicopter confirmed

having reached 1500 ft height and transmitted the ETA Jodhpur at 1040 with

1155 QNH. At 090642 UTC, the ASR advised helicopter to report its position at 30

miles north of AAE and establish contact with the Control on 123.75 MHz. At

090740 UTC, the helicopter relayed its position to ACC as 30 NM on R-007 at

1500 ft on QNH 1005 hPa. The helicopter was not responding to the call. ASR

relayed the message through JAI 2065. At 090805 UTC, JAI relayed the message

and confirmed that the helicopter was in contact with the Control on 123.75 MHz

and reporting at 30 NM at radial 007 AAE. PIC did not report any sort of

abnormality / technical malfunction during the operations.

The helicopter remained in contact with ACC on frequency 123.75 Mhz till

0907 UTC. ON Route Radar the helicopter painted till 0911 UTC and then the

target dropped off at a distance of approximately 37 NM from Ahmedabad (AAE).

1.10 Flight Recorders

CVR and FDR were not installed on the helicopter as these are not

required as per the regulations.

16

1.11 Wreckage and Impact Information

The accident site is approximately 25 km West of Abu Road. The

coordinates of accident site are 24˚32’33” N, 72˚38’35” E.

The accident site is a hilly barren land with slight slope and embedded with

stones. As per the Eye witness No. 1 helicopter made a right turn before impacting

the ground at approximately 40 meters from the flight path. The helicopter impacted

the accident site in a squarely manner i.e. vertically. There was no forward motion of

the helicopter after the impact. Wreckage of the Helicopter was found confined at

one place approximately in a radius of 20 feet. Due to impact its fuel tank burst and

fuel spread all over the area, resulting in fire which consumed entire cockpit area.

Observations made at the accident site are as given below:

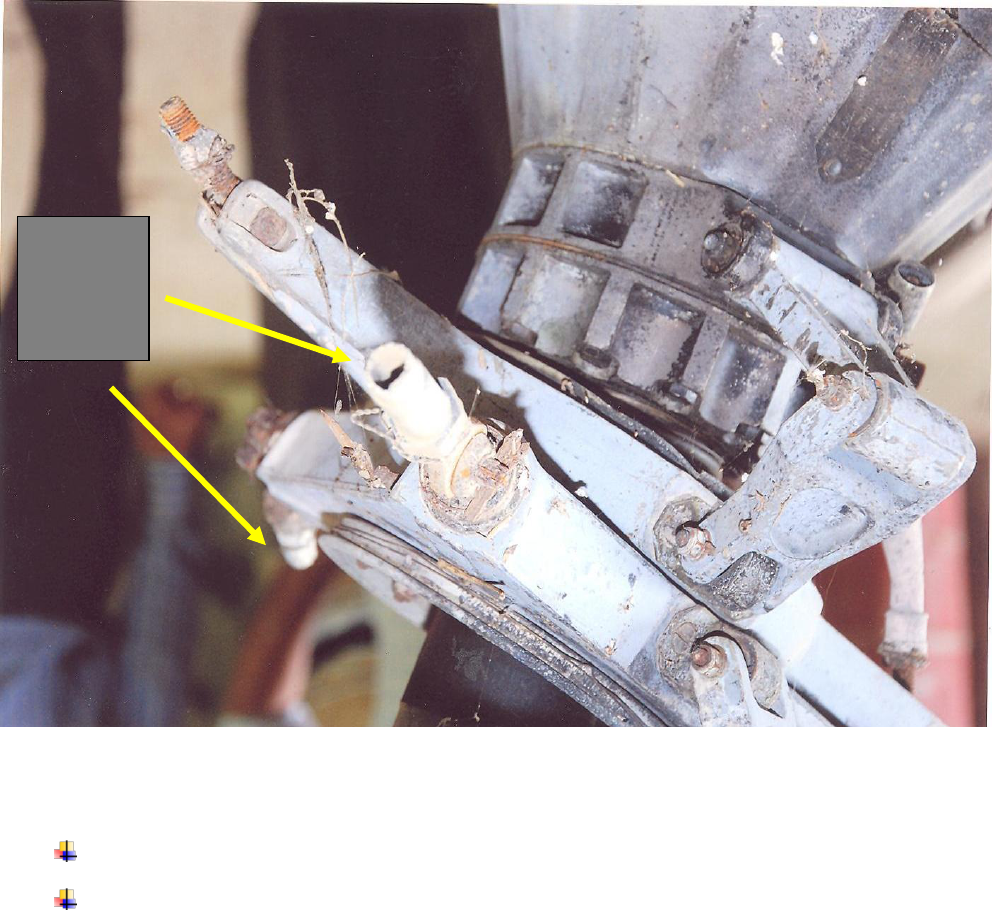

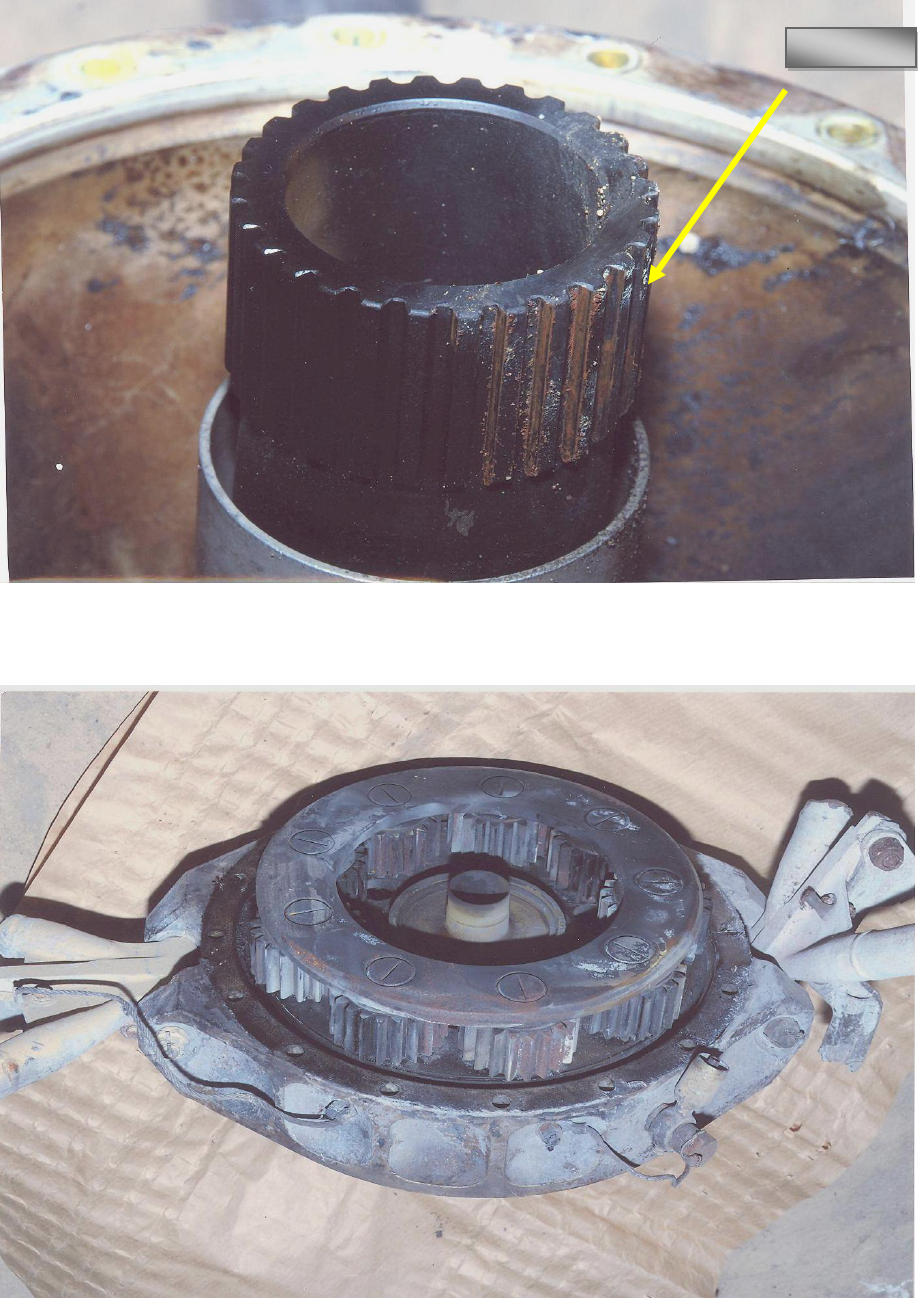

One of the Spacing cable was found attached to its Posts on both sides (Fig.3).

The two other Spacing cables, though anchored to one end of their respective

Cable Posts, had got detached from the link chains attached to the third Cable

Post (Fig.3). The Attachment bolt of one Chain Link had sheared off and the free

end of the detached cable was found near the engine RG casing end. The

Attachment bolt of its second Chain Link though still intact had been pulled out

from its nut end. The link had opened outwards thereby, letting the Spacing

Cable end to come out. This free end of the second Spacing cable had lost its

bush insert and was found lying beneath the Rotor Assembly.

One of the three Hydraulic Drag Dampers had got burnt and the other two were

found badly damaged due to impact.

17

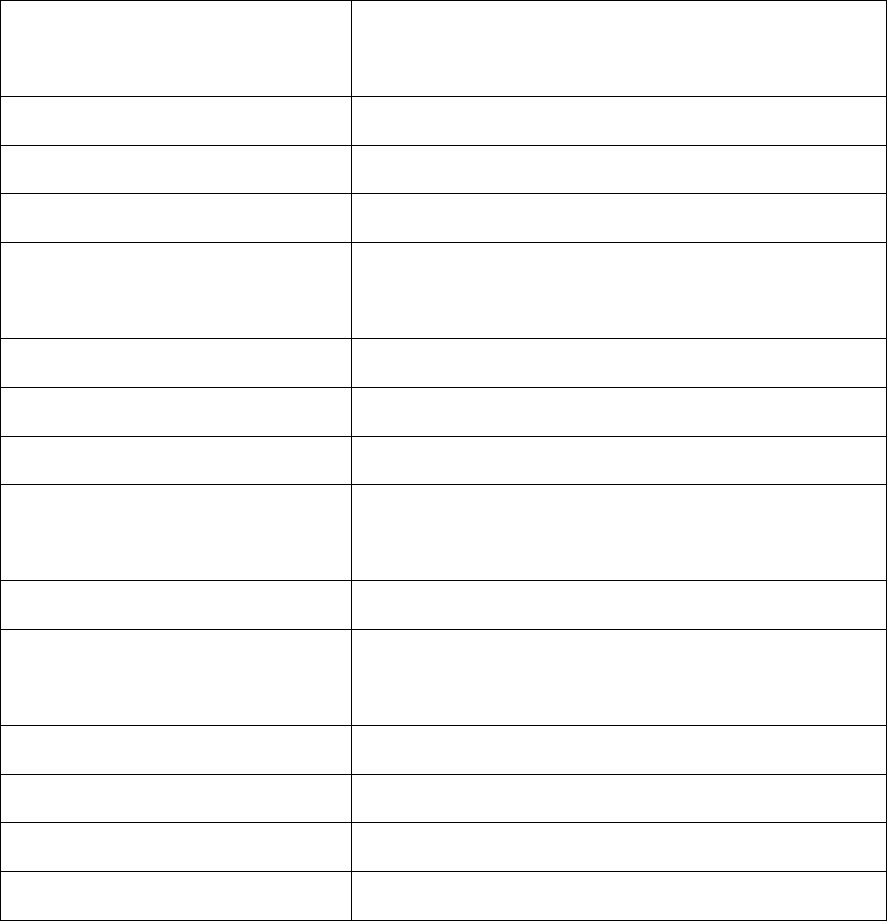

Fig.No 2 View of the Accident Site with the Direction of Approach to the site

One Main rotor blade (MRB) had sheared off due to clean shear, approximately 2 ft

from its root end. The other portion of the Main rotor blade was also lying nearby.

Being on the sloppy ground, it had escaped fire damage to great extent. The other

two MRB’s were partially destroyed in fire and there was no indication that these

blades had rotated (cart wheeled) and grazed after hitting the ground.

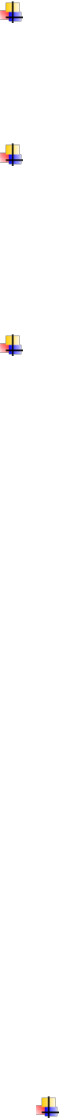

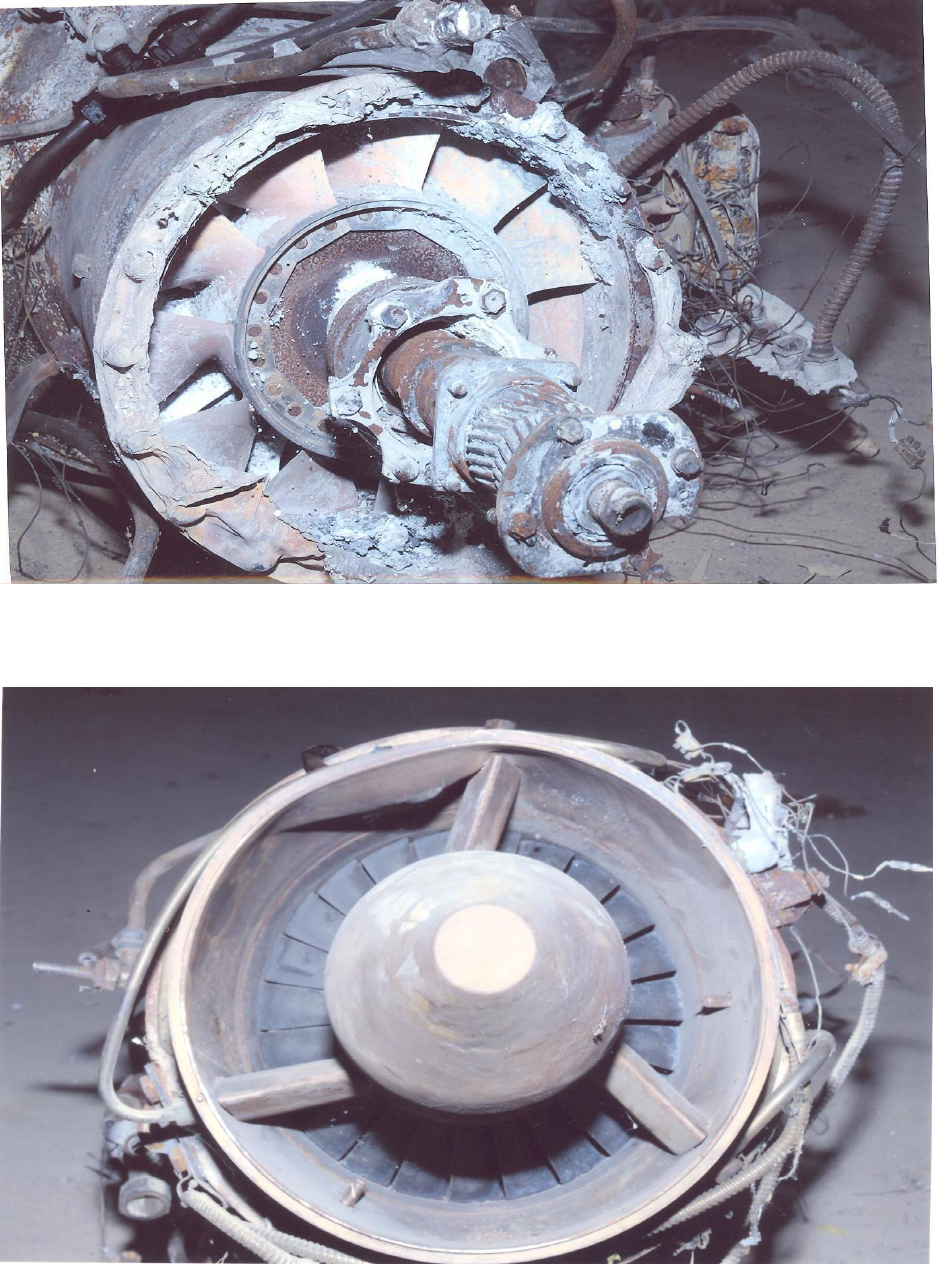

All the three Pitch Change Rods were found broken but attached at both the upper

as well as the lower ends. The Pitch Change Tubes were found completely burnt off.

The Freewheel/Drive Shaft and Clutch Unit were found damaged internally by fire.

The Inclined Drive Shaft & universal Joint were found fire damaged

DIRECTION OF

HELICOPTER

COCKPIT PORTION

ROTOR BLADE

AFT PORTION

ROTOR BLADE

18

Fig-3 Main Rotor Hub Assembly with the severed spacing cables

The Tail Boom up to the Horizontal stabilizer stage was found burnt. The Tail drive

shaft was found attached to the tail boom and the TGB but the fire damaged near

the Tail Boom attachment side.

Tail Gear Box, Spider Mechanism and Tail Rotor Hub were found intact but ceased

may be due to heavy impact.

Two Tail Rotor Blades (TRB) were found attached with Tail Rotor Shaft and third

Blade was found to have sheared off near its root end. No TRB had any sign of

grazing the ground due to impact while in rotation.

SEVERED END OF

THE CABLE

SEVERED END OF THE

CABLE

CABLE

POST

19

Fig.4 MGB Transmission showing the damaged pitch change rods

Only a couple of pieces of Tail Rotor Guard were left on the ground.

The Power cable of the Portable Refueling Pump was found lying approximately 100

feet away in the front side of main wreckage thereby indicating that it got detached

from the pump and was thrown out of the cabin when the Perspex of the cabin

shattered due to heavy impact with the ground.

DAMAGED

PITCH

CHANGE

RODS

20

Fig. 5 Tail Portion of the Helicopter showing the Tail rotor Blades

Portable Refueling Rubber Hose & Nozzle was found lying at approximately 60 feet

away in the front side of main wreckage. Two HF Communication boxes were

recovered from about 60 ft on the front side of the wreckage.

Large number Plexi-glass pieces of the wind Screen were found lying scattered on

the front side of the wreckage area.

The entire Cockpit with its Instrument Panel, Control sticks, Seats and the occupants,

Tech Log Book, Aircraft documents, Log Book of the Co-pilot and the Air borne

toolbox were reduced to ashes due to the intense fire.

The Transmission Platform with the Fuel Tank under it and the entire Baggage hold

compartment in the Aft -Section of the fuselage together with the Communication

Equipment and the Alkaline Battery were completely destroyed in the fire.

BENT ROTOR

BLADE

DETACHED

ROTOR BLADE

21

1.11.1 Examination of the Wreckage in the Hangar

The wreckage of the helicopter was relocated to BSF hangar at Safdurjung

airport for the purpose of post accident examination. Following are the

observations:

State of Airframe

(a) Cockpit

Cockpit portion was totally destroyed in fire. OAT (‘S’) & ADE

Receivers (two) were picked up at 50 feet from the main wreckage.

All the instruments were destroyed in fire. Portable fire extinguisher

and portable refueller were also destroyed in fire.

(b) Central Section

Totally destroyed in fire.

(c) Aft Section

Battery (Battery/radio composition) Radio equipment (VFH/UHF)

all destroyed in fire. Fuel Tank – no trace left other than fiber glass

outer covering as bits and pieces had scattered within 50 feet from

the main wreckage.

(d) Tail boom

Forward portion completely destroyed in fire. Tail section

including horizontal stabilizer was intact. Vertical fin was damaged

due to impact. Tail rotor had broken. Tail rotor (TR) guard had

22

broken. Tail Gear box was intact with two TR blades, and was bent

due to impact. One TRB sheered off at the cuff due to impact. No

grazing of TRB tips on ground indicating either they were freely

rotating at a very low rpm or had stopped rotating.

(e) Aero-engine

RG casing fully destroyed in fire. Power Output shaft engaged and

visible. Speed Governor, oil pump partially destroyed in fire.

Compressor housing, air intake destroyed in fire. Combustion

Chamber casing intact. Turbine casing intact. No rubbing marks

inside the casing. Exhaust Jet pipe intact – partially dented due

impact. Dual coil ignition, AC Box and starter generator, Particle

separator were completely destroyed in fire. Torch igniters in

position.

(f) M.R. Transmission

Free wheel & shaft partially destroyed in fire. Clutch Unit

intact but seized.

i) Main Gear Box

Magnesium casting was totally destroyed in fire along with

external monitoring like tachometer, oil pump. Lower bevel

gear intact. No signs of wear /broken teeth or metal

deposition. Crown worm gear intact, no signs of abnormal

wear or breakage of teeth.

ii) Main Rotor Shaft

No damage was observed to the shaft.

23

1.12 Medical and Pathological Information

The post mortem examination of crew and passengers was carried out.

The cause of death has been given to be shock due to whole body injuries and

burns. All injuries were ante mortem in nature.

1.13 Fire

Entire cockpit area was consumed in fire. Examination of the wreckage

indicated the fire to be post impact. Due to impact the fuel tank burst. This

caused spillage of the fuel and fire.

1.14 Survival Aspects

The post mortem examination of crew and passengers indicated the cause

of death to be shock resulting from burns and multiple injuries. The helicopter

impacted the ground in squarely manner from a height. This was followed by the

intense fire which consumed the entire cockpit. The accident was not survivable.

The Eye-witness immediately intimated the police about the accident. The police

and fire tender reached the site of the accident within half an hour, and spread

foam and water on the burning helicopter. All the occupants of the helicopter

(pilot & co-pilot, AME and the BSF official) were charred inside the helicopter.

At time 1209 UTC, a telephone call received at Aerodrome Control Tower from

the office of IG, BSF, Jodhpur that VT-EQL had not reached the destination.

At time 1215 UTC, Area Controller Tower was informed by BSF about a possible

crash of helicopter near Sirohi and that the helicopter could be VT-EQL taken off

from Gandhinagar for Mandore departed at 0855 UTC estimate FIR 1030UTC

and ETA Mandore 1155 UTC (as per FPS).

24

WSO, Ahmedabad, immediately initiated search and rescue alerting actions and

informed all concerned including RCC Mumbai and Delhi due to the proximity of

the probable crash site being in the border of Delhi/Mumbai FIR.

At time 1357 UTC SP, Sirohi, Rajasthan was contacted by Jt GM (ATM) who

confirmed that helicopter VT-EQL had crashed in Bhimhguda in Fatehpura village

in Bahadurpura Gram Panchayat in Girwar Police Chowki, 25 Km from Abu Road

and BSF rescue team had also reached the site.

The crash site was at 25 Km west of Abu Road at radial 275/72 NM from UUD

VOR and radial 360/98 NM from AAE VOR which was approx 61 NM further

from the last point of two way communication with ACC Ahmedabad.

1.15 Tests and Research

1.15.1 Tear down inspection of Main Gear Box

Tear down inspection was carried out at BSF hangar under the

supervision of Committee of Inquiry.

History and related Data

Part No. : 319A.62.00.000.3

Serial No. : CH-435

TSO : 512:55 hrs.

External Observations

No damage was observed on the upper portion of Main Gear Box (MGB),

Main Rotor Shaft and Main Rotor Head Assembly. The lower portion (Magnesium

casting) of MGB was completely burnt /melted away exposing the Crown and

worm gear.

25

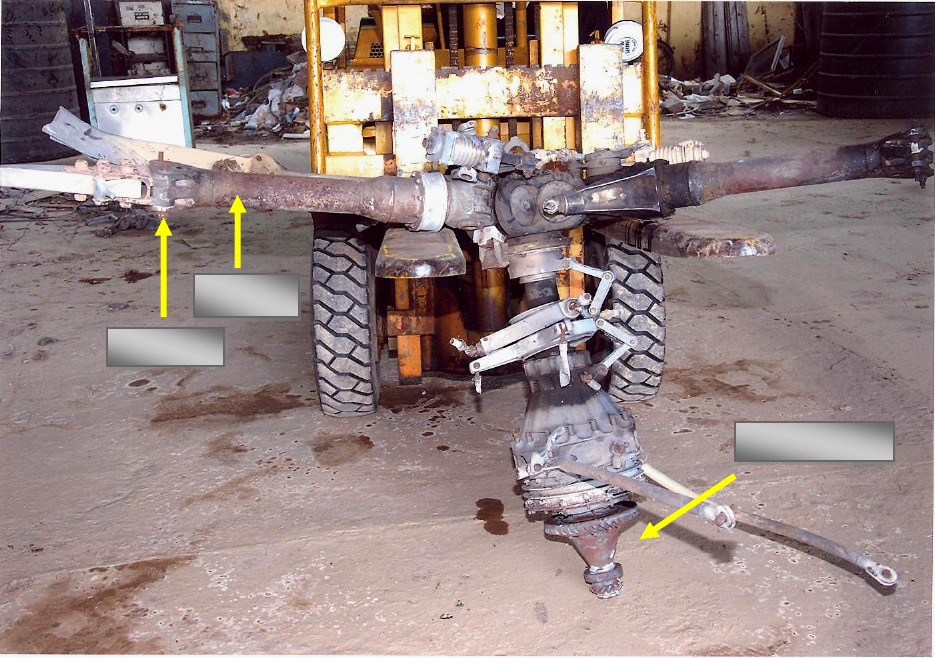

Fig. 6 View of Transmission

Examination on Disassembly

The MR Head & Shaft were removed from the Assembly. The top case was

removed, which exposed the carrier and ring gear. All the male splines on the root end

of the MRS and female splines on the mating gear head were found undamaged.

The Ring gear together with Planetary gears were found undamaged and freely

rotating even after the huge impact and the violent fire. All the eight gears were intact

(Fig. 7). They were freely rotating with no sign of seizure or breakage of teeth. Central

gear was intact. No signs of abnormal wear or breakage of teeth were observed.

The Crown & Worm gear teeth also did not exhibit any damage, galling or pitting.

LOWER CONE

HINGE

SLEEVE

26

Conclusion:

The transmission gears were in good condition. No breakage, pitting, galling was

observed. The gears in the transmission were capable of smooth transmission of

power.

Fig. 7 Ring Gear

27

Fig. 8 Main Rotor Drive Shaft

Fig. 9 Planetary Gears

SPLINES

28

1.15.2 Main Rotor Head

MRH Sr. No. AH 116

Spacing Cable Sr. No’s

a) 30172

b) 30324

c) 30203.

One Attachment Bolt was found to have sheared off, and the link bent

outwards, thereby letting the Cable to get disengaged from the post. The second

Attachment Bolt was found to have come out of the Link after bending the Link outward

through 90 degrees and disengaging the cable end from the post. Deep scoring marks

were found on the swaged end of the cable Sr. No. 30172. The inner bushes of eye-ends

of the cables Sr. No. 30172 & 30324 were missing.

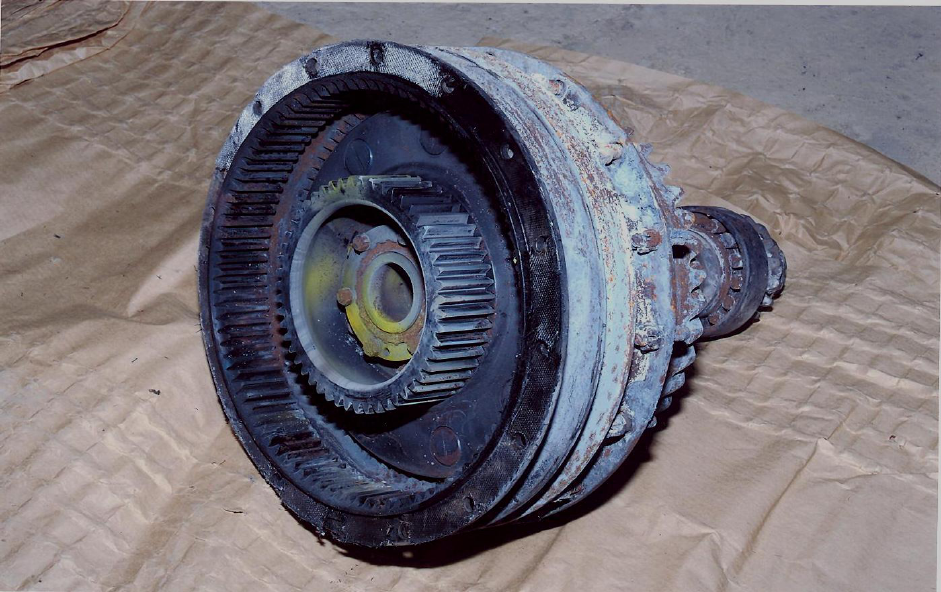

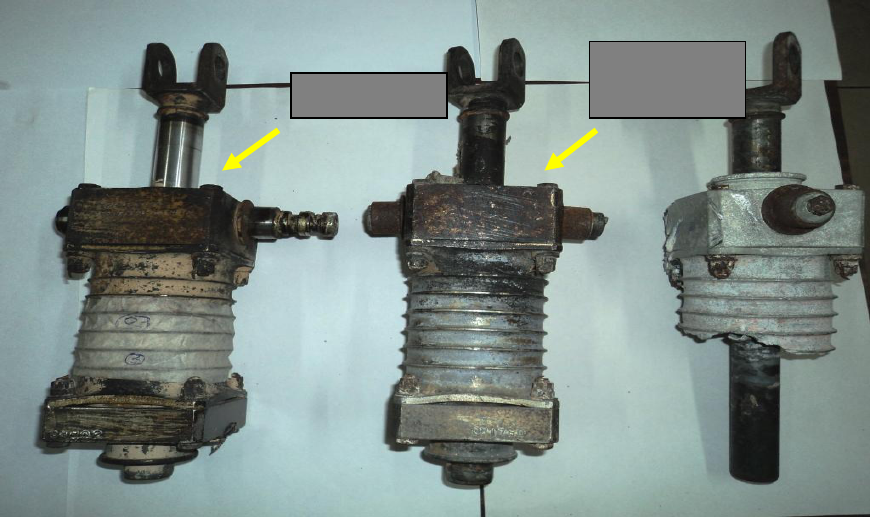

1.15.3 Hydraulic Drag Damper Assemblies (Sl No(s). CH-802, CH-1779 & CH-1780)

Damper Sl No. Ch 802 & 1780 were found mounted on the Drag Hinge

Pins of MRH. The sight gauges were found to have broken and pistons of two dampers

had ceased. The body of the third Damper was found to have burnt off. Therefore, the

serial no. of the third damper could not be ascertained.

Fig. 10 Hydraulic Drag Dampers

SL No. CH 802

SL No. CH

1780

29

1.15.4 Inspection of Engine

The Artouste IIIB Aero Engine Sr No.H-55484 was found intact. It exhibited impact

and fire damage.

Fig. 11 Right Side view of the engine

The Magnesium Reduction Gear Casing of the Engine had got

completely burnt /melted, with all the gear train in position. The Fuel

Pump, Governor Assemblies etc had partially got melted.

The Compressors & its housing, Combustion Chamber, the Turbine discs

were found to be intact.(Fig. 11)

None of the blades of Ist stage centrifugal compressor exhibited

breakage, impact or foreign object damage. (Fig. 12)

There was no evidence of the Turbine blades having grazed the turbine

casing. ( Fig. 13 )

The exhaust section of the engine was found unburnt and attached to the

Engine Turbine casing.

30

Fig. 12 Inlet to Ist Stage Compressor

Fig. 13 Last Stage Turbine Blades

31

Conclusion:

There was no failure of the engine or the bearings.

1.15.5 Metallurgical Examination.

1.15.5.1 The Spacing Cables, Mounting Posts (Spindle) and Attachment Bolts

& Links had been removed by the Inspector of Accidents appointed

by the DGCA for Material Failure Analysis at DGCA R&D Laboratory.

These parts were recovered from the Lab together with the Initial

Report and sent to NAL for material Failure Analysis for second

opinion.

1.15.5.2 Three fractured pitch change rods and the components belonging

to the Spacing Cable Assembly of Chetak helicopter VT-EQL were

forwarded to NAL laboratory for establishing the mode of failure.

NAL carried out the fractographic examination and they have given

following conclusions:

Fractographic analysis confirmed that the pitch change rods and the

Bolts/bushes of the attachment links with the trunnion as well as the cables had

broken by overload fracture. The failure of the bushes of the bolt of the

attachment link with the trunnion indicates that the bolt had experienced very

high load. This in turn indicates that there was excessive load on the attachment

link. This is further substantiated by the deformation marks on the shank of the

fractured bolt and also, bending of one of the fork arms of both the attachment

links. The deformation pattern on the fork of the links suggests that excessive

tension in the spacing cables was responsible for the fracturing of the bolt. In the

sequence of failure, fracture had occurred first at the bolt-head end. Following

this fracture, the whole load on the spacing cable was supported by one of the

arms of the links, leading to bending in a direction out of the loading plane. The

32

bending of one of the fork arms along with the fractured part of the bolt would

also allow the cable anchoring end to come out of the attachment link.

Examination of pitch change rods revealed bending of the pitch change

rods preceded the fracture. This indicates that rods were acted upon by bending

load during the fracture. There were no evidences of progressive failure such as

fatigue or stress corrosion or cracking in any of the pitch change rods.

1.15.5.3 Visual and macro examination of failed Spacing Cable bolt was carried out at

Metallurgical examination laboratory of the DGCA. The report concludes as

follows:

“Presence of the equiaxed dimples and shear dimples on the fractured surface of

the shank portion of the threaded end and head end of the failed bolt

respectively indicated that bolt had failed under overload condition.”

1.15.6 Examination of fuel samples

A sample of fuel of the same barrel as was used on the helicopter was

obtained and subjected to examination at Indian oil Laboratory at Ahmedabad.

As per the examination report received there was no abnormality in the sample.

1.16 Organisation and Management Information

1.16.1 Border Security Force (BSF)

BSF Air Wing was established in the year 1969. Presently, BSF Air Wing is

maintaining and operating 01 Embraer, 02 Avro, 01 SKA B200 Aircraft, 08 Dhruv

(out of which 07 have been delivered to BSF by HAL manufacturer) and 01

Cheetah Helicopter at different location under civil registration as per DGCA.

Whereas, 06 MI IV Helicopter are under military registration.

33

BSF Air Wing was approved under CAR 145/ CAR-M on 11

th

July, 2011

for maintenance and operation of aircraft in airworthy standard. The line

maintenance on Embraer, Avro & SKA B200 aircraft is carried out by BSF.

Whereas, Major Maintenance work is carried out by CAR-145 AMOs. The

maintenance of Dhruv, Chetak/Cheetah helicopter is carried out by HAL/PHHL on

contract basis.

Operational Control

BSF has operations and maintenance contract with M/s Pawan Hans

Helicopters Ltd w.e.f. 29

th

Sept., 2010. After studying the O&M contract between

the two parties, the relevant clauses of the contract can be stated as:

To maintain records in respect of consumption of stock, spares, POL

authorization books and other such documents as prescribed by

Government (DGCA/AAI) and will send monthly statement/return

to BSF air wing and concerned BSF Headquarters.

Operation and maintenance agency will provide consultancy

services on aviation matter, which are incidental for maintenance

and operation of helicopters.

To maintain complete flying records, manifest returns and any

other returns required from time to time for flying and

maintenance of the helicopters as per the requirements of

DGCA/AAI/IAF/ Government and maintenance manuals.

However it was found that neither of the parties was exercising any

operational control and due to which no crew related records/ documents

were maintained by any of the party. Although both the organisations

have elaborate operations setup, the BSF assigns operational task to PHHL

for making the aircraft and the crew available. However neither of the

34

parties was monitoring the FDTL of the crew, currency of their rating and

qualification before operation of the flight.

Maintenance control

1.16.2 Summit Aviation Limited

For the period from 1989 to 2010, the maintenance of the helicopter was

with M/s Summit Aviation. A review of the maintenance record indicates the

following discrepancies:

The log cards were not maintained properly. In a few instances the

original log cards were missing.

A few log cards were raised without the authentication by

concerned AME or without the certificate/label from the

OEM/Overhaul agency (HAL).

The airframe hours at which the component has been fitted on the

aircraft have not been entered.

After the tail rotor strike incident on 30.01.2005, a set of the drag

dampers earlier installed were not found in the inventory of the BSF

or issued to them by the BSF.

1.16.3 Pawan Hans Helicopter Limited (PHHL)

PHHL signed a contract with BSF for O&M of Cheetah and Chetak

Helicopter on 29th Sept 2010. The scope of the contract included "to arrange

suitable/qualified pilots, engineers and technicians for undertaking operation

and maintenance activities including quality control of Cheetah and Chetak

Helicopters within the framework of DGCA rules at Srinagar and Jodhpur".

The routine contract was for maintenance up to 400hrs/2 yearly inspection

for which PHHL was approved vide DGCA Letter ref PHHL/F-APP/2876 dated

35

29.12.2010 under A3 Rating for Jodhpur Sub Base after due inspection of the

base. The following discrepancies were observed:

Aircraft log books for the year 2005 to 2010 were not available.

It appears that M/s PHHL did not exercise any quality control over

the maintenance activities of their AME.

They did not possess copies of the maintenance manual and other

technical literature for preparing and updating the aircraft

maintenance program on the basis of which call outs are required to

be issued.

There was frequent rotation (weekly/fortnightly) of the technicians at the

outstation maintenance Bases. The rotation of the personnel was carried

out without any consideration for the relevant skill, level of experience

and to ensure the continuity in the maintenance activity.

M/s PHHL while taking over the O& M contract did not exercise due

diligence. There was no handing over and taking over or inspection of the

records, facilities and spares.

Inventory of rotables/special equipments and consumables was under the

charge of BSF but were being utilized by PHHL. The inventory control was

found to be deficient in terms of:

a) Curing dates and the shelf life of the hoses were not mentioned.

b) The list of components was not complete and updated.

c) There was no tracking of the components sent to HAL for the

purpose of maintenance/investigation of the components for e.g.

drag damper serial no. CH-524, CH-525, CH-526 removed on

23/12/2008 were sent to M/s HAL for maintenance. The same have

not yet been received back as per the inventory.

d) Calibration record of special tools and testers were not made

available to the committee for the verification purposes. Apparently

the calibration records are not being maintained.

36

1.16.4 Surveillance of maintenance activities by BSF

VT-EQL was based at Jodhpur. BSF has never carried out the surveillance/

audit inspection of the Jodhpur base and the maintenance activities by the AMO

on their helicopter. They have a Quality Manager; however as per the

organisation his scope of work was limited to the fixed wing aircraft. The

oversight of the maintenance activity of helicopter was left to the service

provider.

After signing of O& M contract with M/S PHHL, BSF did not exercise due diligence

in handing over of documents and equipments to the AMO formally.

1.17 Additional Information

1.17.1 Chetek Helicopter accidents that occurred in the Indian Air force in the

year 1978 and 1979 respectively.

Sno

Date

Brief description

1.

3

rd

November,

1978

This accident was probably due to failure of

hydraulic Drag Damper in Flight thus imposing

excessive load on the blade spacing system

resulting in the breakage of links.

2.

01

st

May, 1979

This accident was probably due to failure of

hydraulic Drag Damper in Flight thus imposing

excessive load on the blade spacing system

resulting in the breakage of links and the broken

spacing cable cut through the two pitch control

rods leading of loss of control of Helicopters.

37

1.17.2 Issue regarding diversion from the flight path while flying on direct routing

on Gandhinagar-Jodhpur sector was discussed with the pilots who have earlier

been flying the same helicopter on the same sector. They have suggested as

follows:

On a direct route from Gandhinagar to Jodhpur, especially in the afternoon hours

during summer months, the visibility in the Arravalli Hills (Mount Abu area)

reduces to between 1000 to 2000 meters. In addition, this area does not have

enough open fields, where a helicopter can be landed safely, in case of any

emergency. Whereas, the area slightly west of the route, has much better

visibility and far lower hills with sufficient number of fields, suitable for putting

the helicopter down, in case an emergency action may so require.

Considering the above factors, it is most prudent, in the interest of safety, to stay

slightly west of track in this area, especially during the summer season during the

afternoon period.

2. Analysis

2.1 Maintenance Aspects

2.1.1 Airworthiness of the Helicopter

The Certificate of Airworthiness of the helicopter was current and valid.

Periodicity of all scheduled maintenance task were maintained. As per the

available records no significant snag has been recorded on this helicopter

since its last C of A renewal on 4

th

April, 2011 except a snag about the RPM

indicator at Gandhinagar. The R.P.M. indication snag was rectified by re-

soldering cable wire as the same has come out of the connector. The RPM

indicator was found recording the RPM satisfactorily on ground run given

at Gandhinagar prior to take off from BSF Helipad. The aircraft was under

the maintenance of CAR-145 approved maintenance organisation. Aircraft

Maintenance Engineer who carried out Daily inspection on the day of

38

accident held A&C Licence and held full scope approval for maintenance of

this type of helicopter. During Gandhinagar-Mandore flight of the day no

snag was reported before the accident took place.

Examination of the wreckage site had revealed that helicopter approached

the accident site after making a right turn and had impacted the ground in

squarely manner i.e. vertically. The force of impact is indicated by the

shattering of front plexi glass at impact. The main wreckage was

approximately 40 meters from the flight path being flown by the

helicopter.

Therefore to detect any malfunction of the Main Gear Box (MGB) its

disassembly was carried out. During inspection it was observed that

Planetary gear system was undamaged and freely rotating. All the eight

gears were intact. They were freely rotating with no sign of seizure or

breakage of teeth. Central gear was intact. No signs of abnormal wear of

breakage of teeth was observed. The Crown, Worm gear teeth also did not

exhibit any damage, galling or pitting. The gears in the transmission were

capable of smooth transmission of power.

To detect any failure of the engine, a detailed inspection of the engine

was carried out. The inspection of the engine revealed the following:

The Magnesium Reduction Gear Casing of the Engine had completely

melted with all the gear train in position. The Fuel Pump, Governor

Unit etc had partially got melted.

None of the blades of Ist stage centrifugal compressor exhibited

breakage, impact or foreign object damage.

There was no evidence of the Turbine blades having grazed the turbine

casing.

It indicates that there was not any failure of the engine or the bearings.

39

The damage to the helicopter structure and its systems was due to

impact and fire.

As per CAR Section 2 Series F Part V, the Certificate of Airworthiness of an

aircraft shall be deemed to be suspended when an aircraft ceases or fails

to conform with condition stipulated in the Type Certificate or C of A,

airworthiness requirements in respect of operation, maintenance,

modification, repair, replacement, overhaul, process or inspection

applicable to that aircraft, or is modified or repaired otherwise than in

accordance with approved procedure, or suffers major/substantial damage

(which requires replacement or extensive repair of any major component),

or develop a major defect which would affect the safety of the aircraft or

its occupants in subsequent flights.

The Helicopter was maintained as per the approved maintenance

programme. The snag reported before the accidental flight was rectified

at Gandhinagar prior to take-off for Mandore. Thus it can be safely

concluded that the aircraft was in airworthy condition to undertake the

flight.

2.1.2 Failure of Spacing cable and attachment bolts

Examination of wreckage at the accident site revealed that one of the spacing

cables was attached to its Posts on both sides. The two other spacing cables,

though anchored to one end of their respective Cable Posts, had got detached

from the link chains attached to the third Cable Post. The Attachment bolt of one

Chain Link had sheared off and the free end of the detached cable was found

near the engine RG casing end. The attachment bolt of its second Chain Link

though still intact had been pulled out from its nut end. Both the links had

opened outwards thereby, letting the Spacing Cable ends to come out. This free

40

end of the second Spacing cable had lost its bush insert and was found lying

beneath the Rotor Assembly. Further all the three Pitch Change Rods were found

broken but attached at both the upper as well as the lower ends. Attachment end

of one of the swaged end of the severed spacing cable Sl. No. 30172 indicated

deep scoring marks.

For establishing the mode of failure the pitch change rods and the

components belonging to the spacing cable post assembly were examined at NAL

laboratory. NAL carried out the fractographic examination and they have given

following conclusions:

“Bolts/bushes of the attachment links with the trunnion as well as the cables

had broken by overload fracture. The failure of the bushes of the bolt of the

attachment link with the trunnion indicates that the bolt had experienced very

high load. This in turn indicates that there was excessive load on the attachment

link. This is further substantiated by the deformation marks on the shank of the

fractured bolt and also, bending of one of the fork arms of both the attachment

links. The deformation pattern on the fork of the links suggests that excessive

tension in the spacing cables was responsible for the fracturing of the bolt. In the

sequence of failure, fracture had occurred first at the bolt-head end. Following

this fracture, the whole load on the spacing cable was supported by one of the

arms of the links, leading to bending in a direction out of the loading plane. The

bending of one fork arm of both the attached links along with the fractured part

of the bolt had allowed the cable anchoring end to come out of the attachment

link.

Examination of pitch change rods revealed bending of the pitch change

rods preceded the fracture. This indicates that rods were acted upon by

bending load during the fracture. There were no evidences of progressive

failure such as fatigue or stress corrosion or cracking in any of the pitch change

rods.”

41

The above result of the metallurgical examination lends credence to the fact that

there was excessive tension in the Spacing Cables which led to the failure of the

Attachment Bolts. As one of the cables was released from the post, it became

free and started hunting thus caused failure of the pitch change rods. Failure of

the Pitch Change Rods was probably due to the hit by the Spacing Cable end.

The cable spacing equalizer system corrects transient disturbance affecting

inter blade spacing to ensure proper 120° angular distribution of the three

blades. Therefore release of one of the spacing cable resulted in imbalance in the

rotor system and led to the release of the other spacing cable from the same

post. The other spacing cable does not indicate much hit marks indicating that it

was released shortly before the impact of the helicopter with the ground.

Centrifugal loads resulting from the rotation of the blades are carried by the

tension-torsion strips in the blade sleeve. If, during rotor operation, the

horizontal motion of a blade is disturbed, two distinct components are used to

overcome the disturbance.

The cable spacing equalizer system corrects transient disturbance affecting

inter blade spacing to ensure proper 120° angular distribution of the three

blades.

The drag hinge dampers limit the horizontal oscillations of the blade by

taking up the loads developed about the drag hinge axis and so facilitate

the action of the blade spacing cables.

The metallurgical examination has indicated excessive tension in the spacing

cable. This excessive tension in the spacing cable may be due to the malfunction

of the hydraulic drag damper. The set of drag dampers recovered from the

accident site were installed on this helicopter on 22/12/2008. These were

installed after the previous set was found to have “Timing out of limits”. The set

had been overhauled at HAL on 06/12/2005 and matched. Two of the Drag

dampers recovered from the site were identified while the third drag damper due

to damage could not be identified as its body had got burnt. However due to the

damage, the three drag dampers could not be subjected to bench check.

42

Inspection of the BSF store inventory indicated that they do not have equipment

for the drag damper timing check. Neither there was any record of their

procuring such equipment. This indicates that their assessment of drag damper

timing was based on estimation and not actual measurements. Therefore snag

may not have been detected at its initiations.

The Hydraulic Drag Damper malfunction in flight would cause severe

vibrations that could not be dampened. The imbalance or hunting movements of

the advancing / retreating Blades would cause transmission of excessive tensile

loads from the Rotor Blade System to the Spacing Cable Posts. This would result

in excessive tensile load which might cause failure of Attachment Bolts /Links.

Review of the similar accidents to the Chetak Helicopters operated by

Indian Air force in the year 1978 and 1979 respectively indicated that these

accidents had occurred probably due to failure of Hydraulic Drag Dampers in

Flight thus imposing excessive load on the blade spacing system resulting in the

breakage of links and the broken spacing cable cut through the two pitch control

rods leading of loss of control of Helicopter.

Thus Malfunction of Drag Dampers caused excessive vibrations, transmitting

tensile load on the spacing Cable system and resulting in breakage of Link

attachment bolt. The spacing cable eye-end got released; whip lashed the pitch

control rods and broke them in quick succession.

2.1.3 Management of maintenance records

Scrutiny of records revealed that the helicopter was involved an incident

on 30

th

January, 2005. Following the incident among other parts of rotor

hydraulic drag damper assembly were sent to HAL for inspection on heavy

landing checks. For the removal of drag damper two Defect reports were raised.

43

1) Dated 10.05.2005, which states that Hydraulic Drag Damper Sr. No CH 802,

CH1779, CH1780 were replaced due as their calendar life was near to

completion.

2) Dated 11.05.2005, which states that Hydraulic Drag Damper Sr. No CH 924,

CH925, CH926 were replaced due incident for inspection purposes. The on

numbers were CH733, CH734, and CH735. However these Sr. No(s) are not

available in the Inventory of BSF.

Neither of Summit Aviation, nor PHHL nor the BSF could provide the Defect

Investigation report of the removed drag dampers.

Neither BSF nor PHHL could provide aircraft logbooks of the helicopter

from the year 2005 to 2010.

Log cards of the components have been locally raised and entries have not

been signed by any authorized person.

Thus from above it appears that for all the years the helicopter was operating

without any review of the maintenance activities of the certifying personnel by

the AMO. No system existed for the upkeep of the maintenance literature,

documents, log books and the stock in the bonded store. In other words

Maintenance Quality Control was non-existent.

2.2 Operation Aspect

2.2.1 Crew Qualification

Both the crew held valid license and were qualified on type. The PIC had a total

flying experience of 2930:00 Hrs out of which 1781:00 Hrs were on Allouette

III/Chetak type of helicopter. The co pilot had total flying Experience of 246 hrs.

all of which was on the type of the helicopter being flown.

44

CAR Section 7 Series B Part XIV requires as under

a) Proficiency Checks. All pilots engaged in commercial operations carrying

passengers shall undergo proficiency checks covering aspects as applicable for

type of helicopter and operator’s role. The proficiency check will be carried out by

DGCA approved examiner twice in a year with not less than four months and not

more than eight months between any two checks.

b) Route/Line/LOFT Check. These checks will be carried out once a year to cover

exercises as applicable to the type of helicopter(s).

For the Co pilot the Proficiency check was carried out on 30

th

April 2010 and then

on 27 January 2011, the next became due on 30

th

April 2011. However the same

has not been carried out. Also the check carried out on 27

th

January 2011 should

have been carried out by 30

th

of December 2010.

Thus there is discrepancy in the currency of the licence of the Co Pilot.

2.2.2 Conduct of the flight

The Crew of the helicopter filed Flight Plan for direct routing from

Gandhinagar to Mandore for an altitude of 1500 ft AGL. The telephonic clearance

was taken from Area Control land line for a VFR flight. The Helicopter departed

from Gandhinagar at 0850 UTC. ATC advised the pilot of the helicopter VT-EQL to

maintain the preferred altitude of 1500 feet AGL on QNH 1005 hpa. He was

further advised to report 30 miles out. Pilot intimated estimates as FIR 1030 UTC

and ETA destination 1155 UTC. Then the estimates were passed on to FIC at 30

miles. The helicopter remained in contact with ACC on frequency 123.75 MHz till

0907 UTC reporting at 30NM on radial 007 AAE. At time 0908 UTC the helicopter

called JAI 2065 to rely the position of 30NM on radial 007 AAE to Ahmedabad

ACC. On route radar, the helicopter painted till 0911 UTC and then the target

dropped at distance of approx. 37 NM from AAE. The accident site was towards

45

the west of the track by almost 12 miles. Apparently the helicopter was following

west of the route. The highest hill in the region on the route was the Mt Abu at

5650 ft. To ascertain the reasons for the deviation, views of the pilots who had

earlier flown the helicopter of type in this region/route was obtained. As per their

opinion

“On a direct route from Gandhinagar to Jodhpur, especially in the afternoon hours

during summer months, the visibility in the Arravali Hills (Mount Abu area)

reduces between 1000 to 2000 meters. In addition, this area does not have

enough open fields, where a helicopter can be landed safely, in case of any

emergency. Whereas, the area slightly west of the route, has much better

visibility and far lower hills with sufficient number of fields, suitable for putting

the helicopter down, in case an emergency action may so require.

Considering the above factors, it is most prudent, in the interest of safety, to stay

slightly west of track in this area, especially during the summer season during the

afternoon period.”

Thus deviation of the helicopter to the West of the route was carried out in the

interest of safety as this region has much better visibility and far lower hills

with sufficient number of fields, suitable for putting the helicopter down in case

an emergency action may so require.

2.2.3 Handling of Emergency

While the aircraft was flying in the Arravalli hill range, to the West of the cleared

route, it experienced the failure of the spacing cable. The released spacing cable

impacted the pitch change rods successively. Due to the load asymmetry in the

rotor system the other spacing cable was also released from its attachment point.

The blade pitch change is controlled by means of rods connected at one end to

the blade horns carried by the blade sleeves and at the other end to the rotating

star or upper swash plate.

46

As the pitch change rods gave way, the pilot lost collective and cyclic control.

Pilot could not put the helicopter in autorotation and flare it for cushioning its

landing. The helicopter virtually stood still in air before falling squarely on the

ground with no tilt towards any side. Before approaching the accident site the

helicopter made a right turn and impacted the ground with high impact force at

approximately 40 metres from the route being flown. This indicates that the

impact with the ground was after falling from a substantial height which resulted

in the burst of fuel tank and helicopter caught fire.

Though the engines were producing power, and transmitting to the rotor

assembly, the crew could not cushion the landing due to loss of control.

3. CONCLUSION

3.1 Findings

3.1.1 The Helicopter was maintained as per the approved maintenance programme.

No snag related to Engine or Tail Transmission system was reported before the

accidental flight. The MGB, TGB, Engine and associated drives were checked after

the crash and no abnormality was observed. Thus the helicopter apparantly was

in airworthy condition to undertake the flight.

3.1.2 The deformation pattern on the fork ends of two links suggests excessive tension

in the Spacing Cables.

3.1.3 Bolts/bushes of the attachment links with the trunnion as well as the cables had

broken by overload fracture caused due to excessive tension in the spacing

cables.

3.1.4 Pitch change rods were acted upon by bending load during the fracture imposed

probably by hitting of the released spacing cable. There were no evidences of

47

progressive failure such as fatigue or stress corrosion or cracking in any of the

pitch change rods.

3.1.5 Probable malfunction of Drag Dampers resulted in excessive vibrations,

transmitting tensile load on the spacing Cable system and resulting in breakage of

Link attachment bolt. The spacing cable end got released; probably whip lashed

hard the pitch control rods and broke them in quick succession. Pilot lost the

Cyclic & Collective control of the Helicopter which resulted in crash landing

without any auto-rotative cushioning available to it.

3.1.6 The helicopter was operating without review of the maintenance activities of the

Certifying personnel by the Quality control of the AMOs. There was no review of

the maintenance literature, documents, log books and the stock in the bonded

store. In other words Maintenance Quality Control was nonexistent.

3.1.7 Both the Pilots had valid endorsement on the type of the helicopter.

3.1.8 There was a discrepancy in the currency of the licence of the Co pilot. The

Proficiency check was carried out on 30

th

April 2010 and then on 27

th

January

2011, the next became due on 30

th

April 2011. However the same has not been

carried out. Also the check carried out on 27

th

January 2011 should have been

carried out by 30

th

of December 2010.

3.1.9 Helicopter deviated to the West of the route while flying in the Arravalli range.

The deviation was carried out in the interest of safety as this region has much

better visibility and far lower hills with sufficient number of fields, suitable for

putting the helicopter down, in case an emergency action may so require.

3.1.10 Before approaching the accident site the helicopter made a right turn and

impacted the ground with high impact force at approximately 40 metres from

the route being flown. Helicopter impacted the ground in the squarely manner

i.e. vertically and with no forward movement.

48

3.1.11 As the pitch change rods broke, the collective and cyclic control was lost. Though

the engines was producing power and transmitting to the Rotor Assembly, the

crew could not cushion the landing due to loss of control.

3.1.12 Neither the BSF nor M/s PHHL were monitoring the FDTL of the crew, currency of

their rating and qualification before operation of the flight. This is how despite

the lapse of proficiency check Co Pilot was allowed to operate this flight. Thus

neither BSF nor M/s PHHL was exercising any operational control.

3.1.13 Following incident on 11.05.2005 a Defect Investigation Report was raised,

which stated that Hydraulic Drag Dampers Sr. No CH 924, CH925, CH926 were

replaced and sent to HAL for inspection. The “ON” numbers were CH733, CH734,

and CH735. However these “ON” Sr. No(s) are not available in the Inventory of

BSF.

49

3.2 Cause of Accident

The accident occurred due to loss of control resulting from probable

failure of Hydraulic Drag Dampers in flight which imposed excessive loads on the

Blade Spacing System resulting in the failure of bolts/links. The severed spacing

cable impacted and broke the pitch control rods, leading to loss of control of

Helicopter.

Lack of oversight of Maintenance Activities of the AMOs was the

contributory factor.

4. RECOMMENDATIONS

4.1 HAL may review the line maintenance practices of the Hydraulic Drag Dampers in

view of a number of malfunctions of the Drag Dampers in the past.

4.2 In majority of fatal accidents involving the private/NSOPs operator unlike the

scheduled operators, the flying and training records of the crew are not

completely available. DGCA may consider issuing necessary instructions to the

industry to ensure that organisations maintain these records independent of the

individual flight crew.

4.3 Action as deemed fit may be taken against concerned AMOs and the operator for

the lack of supervision of the operational and maintenance activities in view of

findings 3.1.6, 3.1.8 & 3.1.12, 3.1.13.

(S.S. Nat) (Captain P.K. Chabri)

MEMBER MEMBER

(Group Captain M.K. Labroo (Retd.))

CHAIRMAN